Aqueous solution retarder

A technology of retarder and water agent, which is applied in the field of water agent retarder, can solve the problems of additive types and high addition amount, environmental pollution, etc., and achieve improvement and improvement of mechanical properties, good adaptability, improvement and easy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

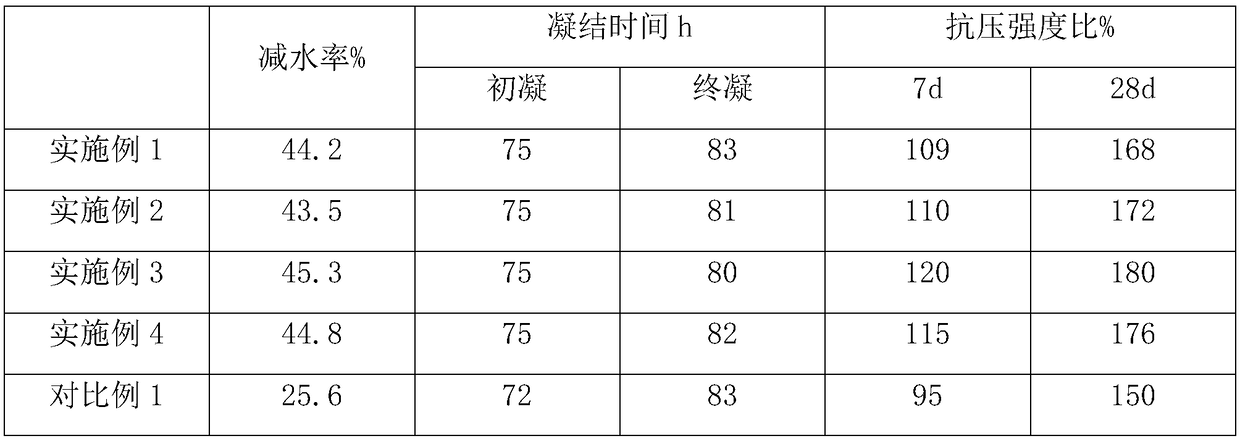

Examples

Embodiment 1

[0028] An aqueous retarder, in parts by weight, the retarder includes polycarboxylate water reducer 70, sodium tripolyphosphate 1, citric acid 5, sodium nitrite 1 and calcium enhancer 1, the The weight ratio of calcium hydroxide, calcium oxide and calcium carbonate in the calcium enhancer is 20:30:1. The preparation steps of the polycarboxylate water reducer are:

[0029] 1) Add methallyl polyoxyethylene ether into a three-necked flask, heat and stir to 40°C;

[0030] 2) Add 30% hydrogen peroxide solution, drop in thioglycolic acid solution, after 5 minutes, slowly add fumaric acid solution for 3 hours, ammonium persulfate solution for 3.5 hours, and keep 40°C for 1.5 hours after the dropwise addition;

[0031] 3) After the reaction is finished, wait for the reaction product to cool down, add 30% sodium hydroxide solution, adjust the pH value to neutral, and obtain a light yellow viscous polymer copolymer solution, that is, a polycarboxylate superplasticizer.

[0032] Mix th...

Embodiment 2

[0034] An aqueous retarder, in parts by weight, the retarder includes polycarboxylate water reducer 75, sodium tripolyphosphate 5, citric acid 10, calcium nitrite 2 and calcium enhancer 5, the The weight ratio of calcium hydroxide, calcium oxide and calcium carbonate in the calcium enhancer is 30:40:10. The preparation steps of the polycarboxylate water reducer are:

[0035] 1) Add methallyl polyoxyethylene ether into a three-necked flask, heat and stir to 40°C;

[0036] 2) Add 30% hydrogen peroxide solution, drop in thioglycolic acid solution, after 5 minutes, start to slowly add itaconic acid solution for 3 hours, ammonium persulfate solution for 3.5 hours, and keep it at 40°C for 1.5 hours after the dropwise addition;

[0037] 3) After the reaction is finished, wait for the reaction product to cool down, add 30% sodium hydroxide solution, adjust the pH value to neutral, and obtain a light yellow viscous polymer copolymer solution, that is, a polycarboxylate superplasticize...

Embodiment 3

[0040] An aqueous retarder, in parts by weight, said retarder includes polycarboxylate water reducer 80, sodium hexametaphosphate 6, citric acid 15, methanol 3 and calcium enhancer 7, said retarder The weight ratio of calcium hydroxide, calcium oxide and calcium carbonate in the calcium preparation is 30:40:15. The preparation steps of the polycarboxylate water reducer are:

[0041] 1) Add methallyl polyoxyethylene ether into a three-necked flask, heat and stir to 40°C;

[0042] 2) Add 30% hydrogen peroxide solution, drop in thioglycolic acid solution, after 5 minutes, slowly add methacrylic acid solution for 3 hours, potassium persulfate solution for 3.5 hours, keep 40°C for 1.5 hours after dropping;

[0043]3) After the reaction is finished, wait for the reaction product to cool down, add 30% sodium hydroxide solution, adjust the pH value to neutral, and obtain a light yellow viscous polymer copolymer solution, that is, a polycarboxylate superplasticizer.

[0044] Mix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com