Environment-friendly PVC (polyvinyl chloride) wood-plastic foamed board material and preparation method thereof

A wood-plastic foaming and environmental protection technology, which is applied in the field of PVC wood-plastic materials, can solve the problems of sound insulation and heat insulation, flame retardant, waterproof, mildew-proof and insect-proof performance, reduced durability in use, affecting product appearance and sales, and uneven bubbles. It achieves the effects of high flame retardant and waterproof grade, superior mildew and insect resistance performance, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

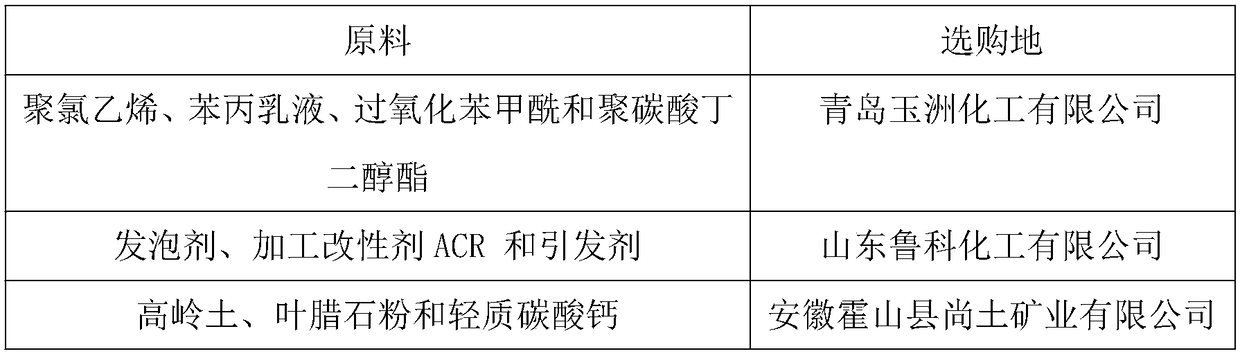

[0027] A kind of environment-friendly PVC wood-plastic foam board, weigh the raw materials of the following table 2:

[0028] Table 2

[0029]

[0030] The above-mentioned modified rice husk is made of the following raw materials: 5 kg of rice husk, 1 kg of far-infrared ceramic powder, 0.4 kg of allyl heptanoate, 0.1 kg of 2-methylimidazole, 1 kg of aromatic polyurethane acrylate, polycarboxylic acid high-efficiency reducing Water agent 0.8kg, nepheline powder 1kg and sandan oil 0.6kg; the preparation method is as follows: first crush the rice husk into 80 mesh particles, spray sandan oil while stirring, mix well and let stand for 4 hours, then mix with other remaining The ingredients are mixed, heated to 60°C, dispersed and ground for 30 minutes, and the modified rice husk required by the raw material of the present invention is obtained;

[0031] The above-mentioned modified sawdust is made from the following raw materials: 10kg of sawdust, 1kg of sepiolite wool, 0.5kg o...

Embodiment 2

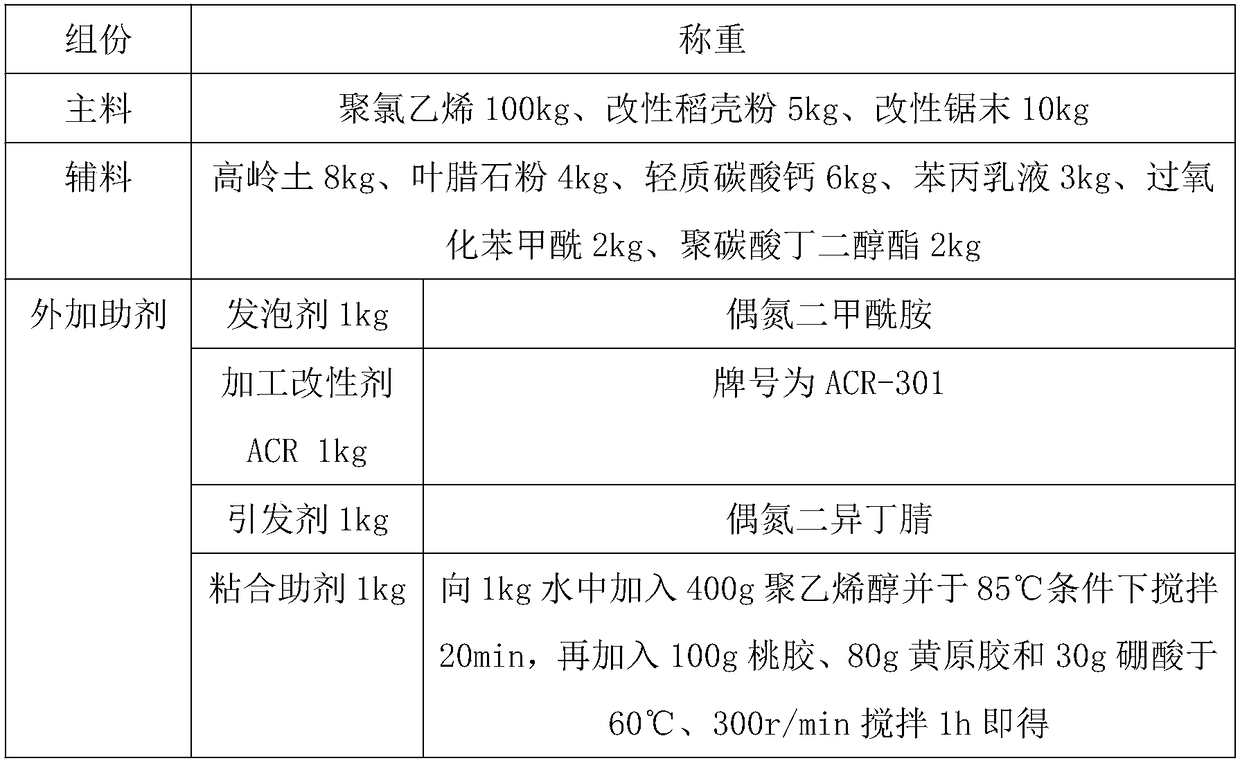

[0038] An environmentally friendly PVC wood-plastic foam board, the raw materials in the following table 3 are weighed:

[0039] table 3

[0040]

[0041]The above-mentioned modified rice husk is made of the following raw materials: 10kg of rice husk, 1.5kg of far-infrared ceramic powder, 0.6kg of allyl heptanoate, 0.2kg of 2-methylimidazole, 1.5kg of aromatic polyurethane acrylate, polycarboxylic acid 1kg of high-efficiency water reducer, 1.5kg of nepheline powder and 0.8kg of sandan oil; the preparation method is as follows: crush the rice husk into 100 mesh particles, spray into sandan oil while stirring, mix well and let stand for 5 hours, and then mix with other The remaining ingredients are mixed, heated to 65°C, dispersed and ground for 35 minutes, and the modified rice husk required by the raw material of the present invention is obtained;

[0042] The above-mentioned modified sawdust is made from the following raw materials: 15kg of sawdust, 1.5kg of sepiolite woo...

Embodiment 3

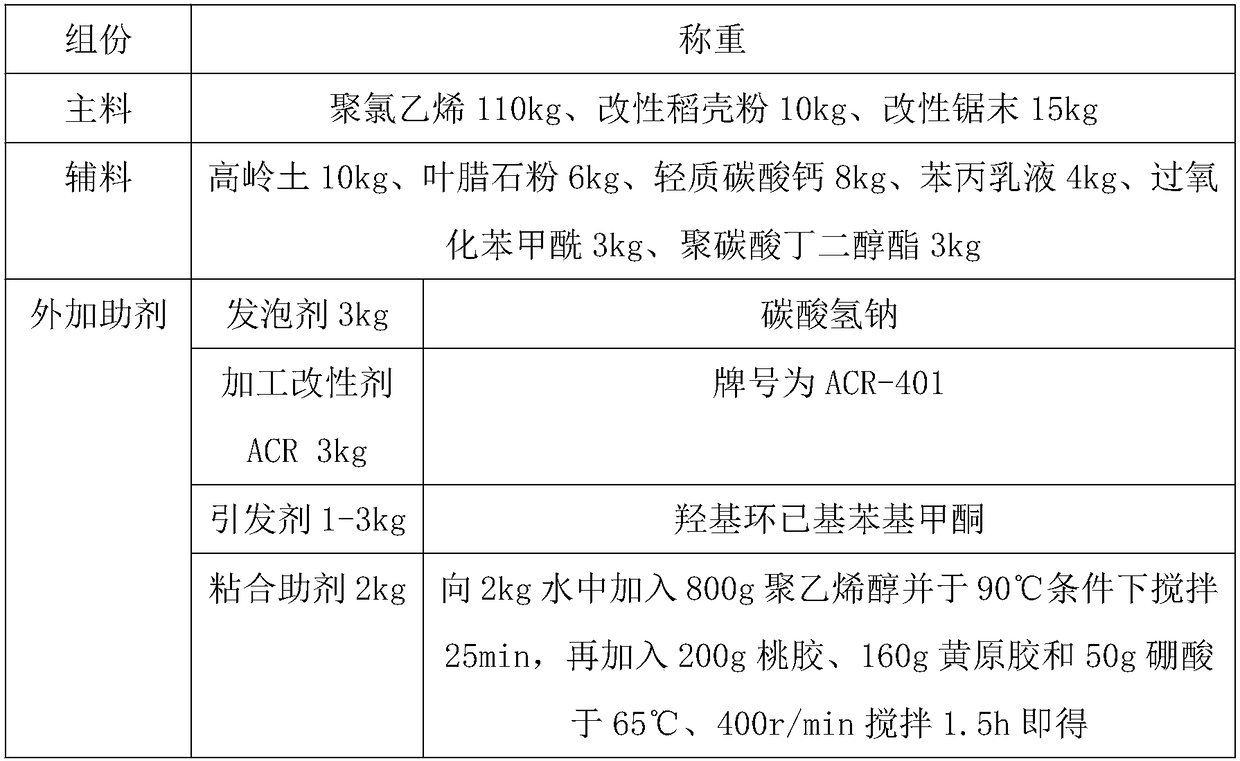

[0049] A kind of environment-friendly PVC wood-plastic foam board, weigh the raw materials of the following table 4:

[0050] Table 4

[0051]

[0052] The above-mentioned modified rice husk is made of the following raw materials: 15kg of rice husk, 2kg of far-infrared ceramic powder, 0.8kg of allyl heptanoate, 0.3kg of 2-methylimidazole, 2kg of aromatic polyurethane acrylate, high-efficiency polycarboxylate Water agent 1.2kg, nepheline powder 2kg and sandan oil 1.0kg; the preparation method is as follows: crush rice husk into 120 mesh particles, spray sandan oil while stirring, mix well and let stand for 6h, then mix with other remaining ingredients Mix, heat to 70°C, disperse and grind for 40 minutes to obtain the modified rice husk required by the raw material of the present invention;

[0053] The above-mentioned modified sawdust is made from the following raw materials: 20kg of sawdust, 2kg of sepiolite wool, 1.5kg of silica airgel, 0.8kg of wood glue powder, 1.0kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com