A cleaning method for high temperature components

A component and high temperature technology, which is applied in the cleaning field of high temperature components, can solve problems such as unevenness, poor painting quality, and peeling off, and achieve the effects of improved high temperature resistance, complete and beautiful appearance, and improved antirust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

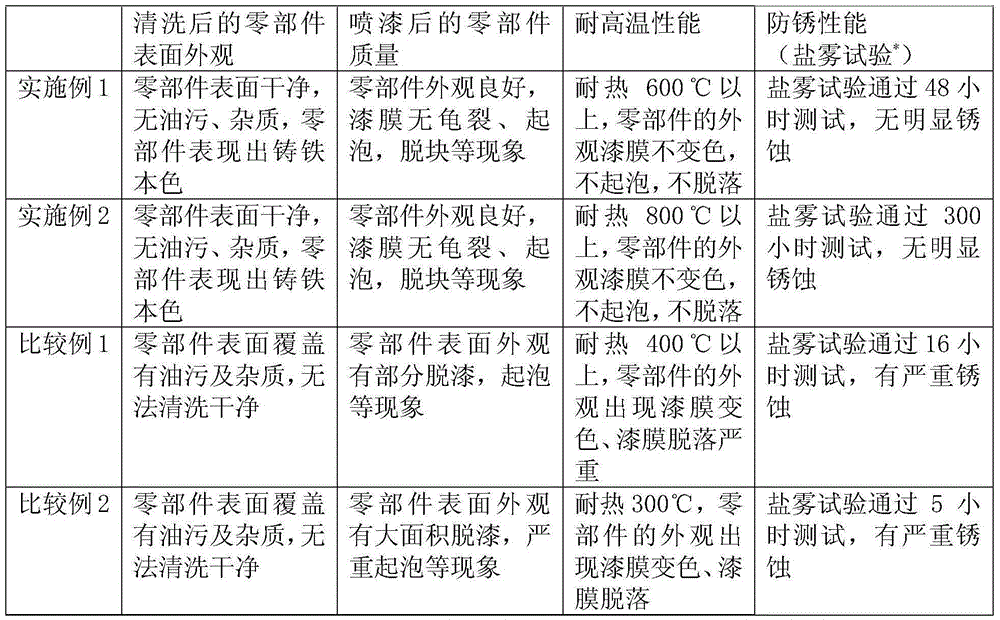

Examples

Embodiment 1

[0024] Embodiment 1. adopt cleaning method of the present invention to clean parts and spray oily high temperature resistant paint

[0025] The present invention takes high-temperature components such as engine exhaust pipe, turbocharger volute, and exhaust connection pipe as examples, and performs the following operations.

[0026] Rinse on high heat. Randomly take 25 of the above-mentioned parts, keep the joints of the parts facing down to facilitate drainage, place them in the cleaning basket, and place each layer staggered. Put the placed cleaning basket into a high-temperature cleaning pool (60x80 Lintai Company), put in NR301 type cleaning solution (Foshan Jintai Chemical Co., Ltd.) with a concentration of 7% by mass, heat to 85°C, and wash for 8 minutes. Each batch uses a refractometer (HT0-5 model) to detect the concentration of the cleaning solution, and controls the reading of the refractometer to remain within the range of 6.5-9. Good cleaning effect.

[0027] Ul...

Embodiment 2

[0033] Embodiment 2. adopt cleaning method of the present invention to clean parts and spray water-based high temperature resistant paint

[0034] The present invention takes high-temperature components such as engine exhaust pipe, turbocharger volute, and exhaust connection pipe as examples, and performs the following operations.

[0035]Rinse on high heat. Get 25 above-mentioned parts at random, keep the pass of parts downwards, be placed in the cleaning basket (same as embodiment 1). Put the placed cleaning basket into a high-temperature cleaning tank (60x80 Lintai Company), put in NR301 type cleaning solution (Foshan Jintai Chemical Co., Ltd.) with a concentration of 9% by mass, heat to 95°C, and wash for 10 minutes. Each batch uses a refractometer (HT0-5 model) to detect the concentration of the cleaning solution, and controls the reading of the refractometer to remain within the range of 6.5-9. Better cleaning effect.

[0036] Ultrasonic cleaning. Place the parts aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com