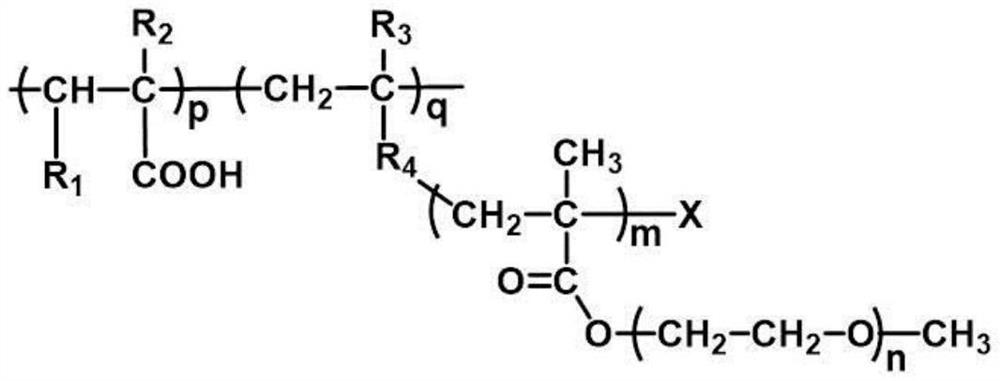

A kind of polycarboxylate water reducing agent, its preparation method and application

A technology of water reducing agent and polycarboxylate, applied in the field of polycarboxylate water reducing agent, can solve problems such as poor workability, insufficient water reducing rate of high-strength concrete, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

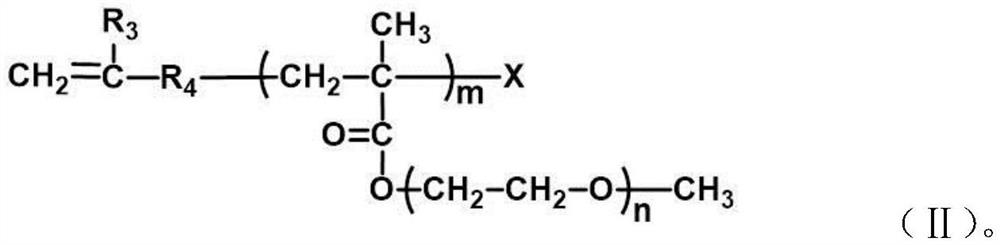

[0054] (1) Synthesis of comb polyether monomer:

[0055] In the flask that stirrer is equipped with, add 3-chloropropene 0.2mol, OEGMA (M w The molecular weight is 300) 4mol, CuCl0.2mol, PMDETA 0.2mol, N 2 30min to remove the O in the solution 2 , then close the system, stir and heat up to 60°C, and react at this temperature for 2h. After the reaction is over, the copper salt is removed by filtration to obtain a comb-shaped polyether monomer, and GPC records M w It is 5150, and the molecular weight distribution coefficient is 1.26.

[0056] (2) Synthesis of polycarboxylate water reducer:

[0057] In the flask that stirrer is equipped with, add above-mentioned synthetic comb polyether monomer 0.1mol (according to M w Molecular weight 5150, total 515g), hydrogen peroxide 0.012mol and water 515g, then stir and heat up to 40°C, at this temperature, add dropwise The mixed solution of the mixed solution, the dropping time is 3h, after the dropping is completed, it is incubate...

Embodiment 2

[0059] (1) Synthesis of comb polyether monomer:

[0060] In the flask that stirrer is equipped with, add 2-methyl-3-chloropropene 0.2mol, OEGMA (M w The molecular weight is 400) 4mol, CuBr 0.2mol, bpy 0.4mol, N 2 30min to remove the O in the solution 2 , then close the system, stir and heat up to 80°C, and react at this temperature for 4h. After the reaction is over, the copper salt is removed by filtration to obtain a comb-shaped polyether monomer, and GPC records M w It is 6850, and the molecular weight distribution coefficient is 1.35.

[0061] (2) Synthesis of polycarboxylate water reducer:

[0062] In the flask that stirrer is equipped with, add above-mentioned synthetic comb polyether monomer 0.1mol (according to M w Molecular weight 6850 calculation, total 685g), ammonium persulfate 0.028mol and water 690g, then stir and heat up to 60°C, at this temperature, dropwise add methacrylic acid 0.6mol, mercaptoethanol 0.0245mol, sodium bisulfite 0.0035mol and The mixed ...

Embodiment 3

[0064] (1) Synthesis of comb polyether monomer:

[0065] In the flask that stirrer is equipped with, add 2-methyl-4-bromobutene 0.2mol, OEGMA (M w The molecular weight is 500) 3.6mol, CuBr 0.2mol, TPEN 0.2mol, N 2 30min to remove the O in the solution 2 , Then close the system, stir and heat up to 100°C, and react at this temperature for 6h. After the reaction is over, the copper salt is removed by filtration to obtain a comb-shaped polyether monomer, and GPC records M w It is 7740, and the molecular weight distribution coefficient is 1.25.

[0066] (2) Synthesis of polycarboxylate water reducer:

[0067] In the flask that stirrer is equipped with, add above-mentioned synthetic comb polyether monomer 0.1mol (according to M w Molecular weight 7740 calculation, total 774g), potassium persulfate 0.009mol and water 775g, then stir and heat up to 60°C, at this temperature, dropwise add 0.8mol of itaconic acid, mercaptopropionic acid 0.0315mol, sodium bisulfite 0.0045mol and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com