A mercury-containing fumes emission continuous monitoring system and a monitoring method thereof

A flue gas form and monitoring system technology, applied in the field of measurement systems, can solve problems such as easy leakage, low reliability, and small amount of sample collection, so as to reduce the possibility of leakage, improve measurement accuracy, and simple system structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

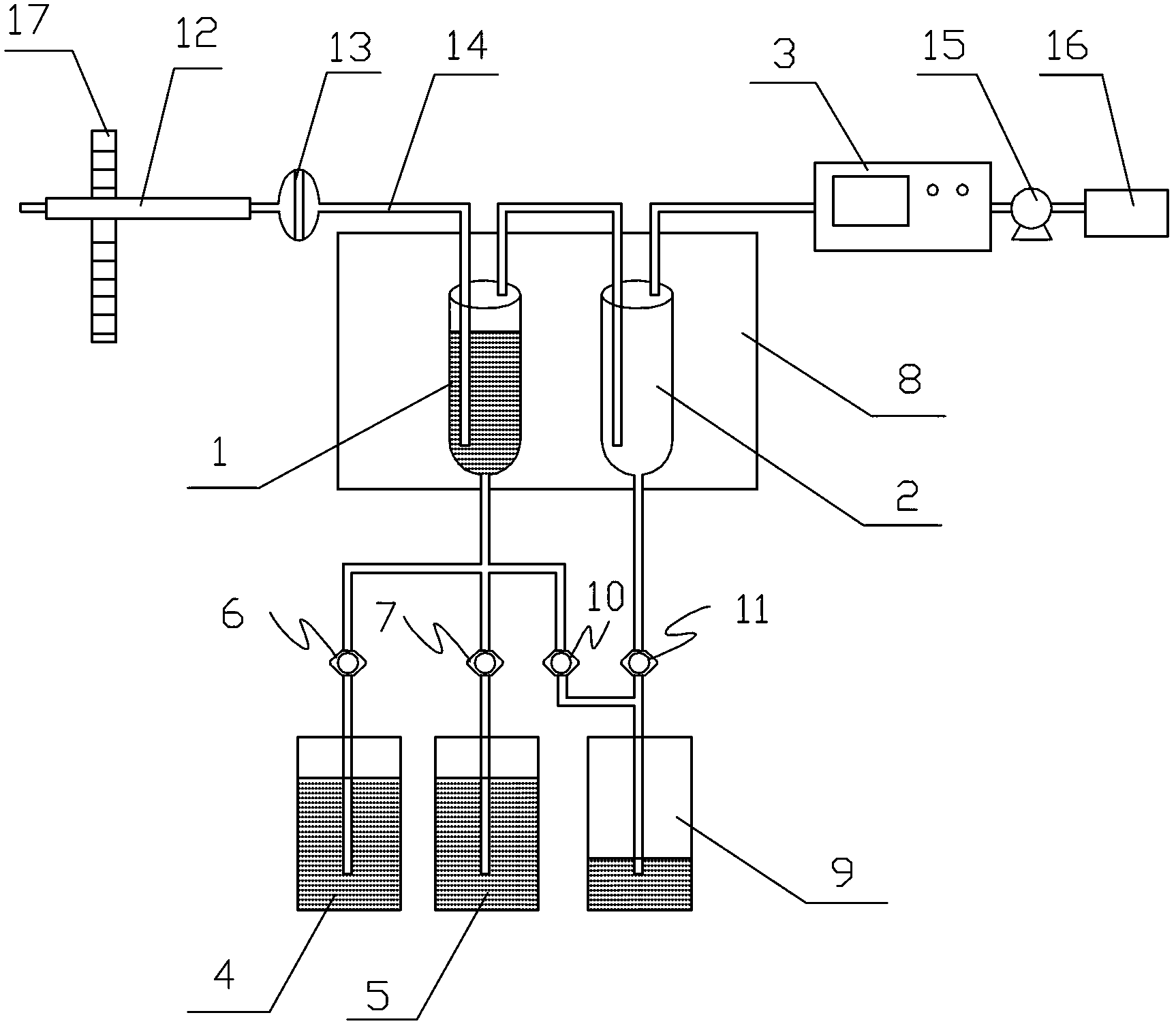

[0026] Embodiment: the flue gas form mercury emission continuous monitoring system of this embodiment, such as figure 1 As shown, it includes a sampling device and a reactor 1 composed of a sampling probe 12, a smoke filter 13, a jet device 15 and an air compressor 16, a gas-water separation device 2, a mercury measuring device 3, a refrigeration device 8, and a first container 4 , the second container 5, the waste liquid bucket 9, the first peristaltic pump 6, the second peristaltic pump 7, the third peristaltic pump 10, the fourth peristaltic pump 11 and the control circuit. The sampling probe 12 is installed in the measured flue 17, the sampling probe 12 is connected with the smoke filter 13, the smoke filter 13 is connected with the air inlet of the reactor 1 through the heat tracing pipeline 14, and the gas outlet of the reactor 1 is connected through the pipeline Connect to the air inlet of the gas-water separation device 2, the gas outlet of the gas-water separation dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com