Demercuration and regeneration method for copper-based demercuration adsorbent

An adsorbent, mercury removal technology, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problem of copper-based mercury removal adsorbents that cannot be recycled simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

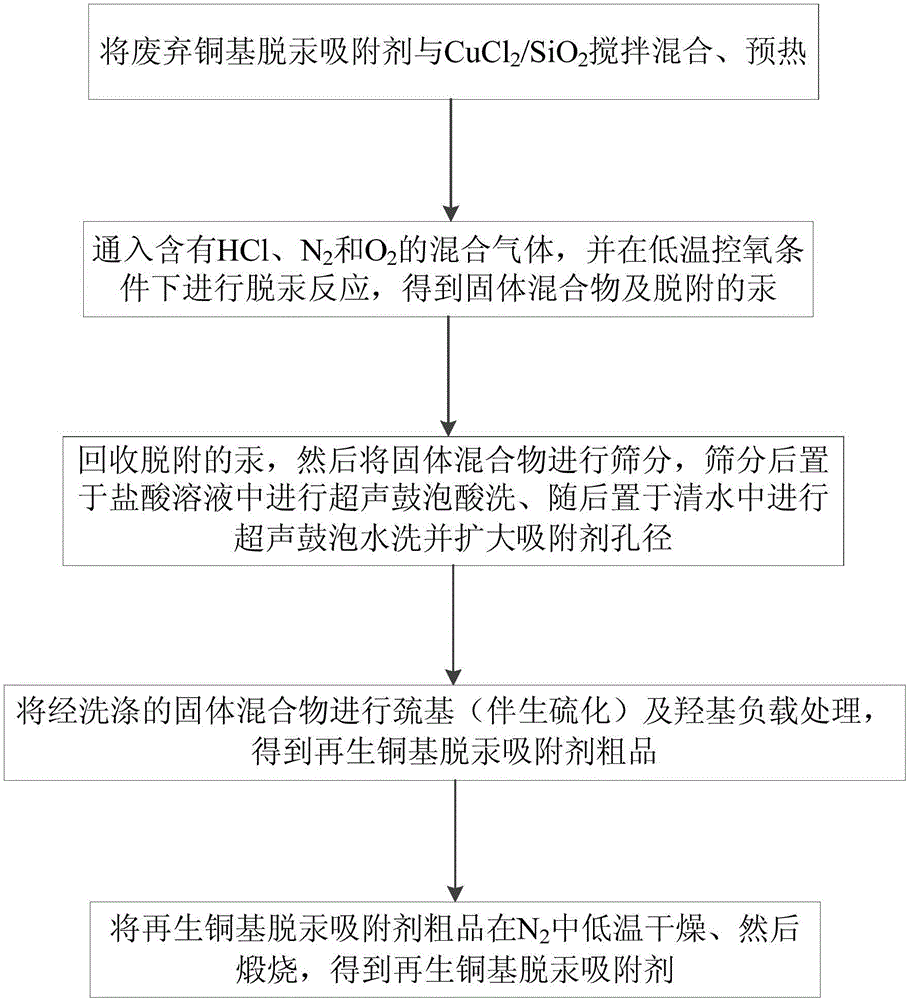

Image

Examples

Embodiment 1

[0053] This embodiment provides a mercury removal and regeneration method for a waste copper-based mercury removal adsorbent, the steps of which are as follows:

[0054] Take the abandoned copper sulfide mercury removal adsorbent with aluminum oxide as the carrier and the low-temperature pyrolysis catalyst in a gas field and mix and preheat in a stirred reactor. The preheating temperature is 50°C and the time is 30 minutes to obtain a preheated mixture; Wherein, the above-mentioned low-temperature pyrolysis catalyst is composed of 90% by mass percentage of copper chloride and 10% by mass of silicon dioxide, and the particle diameter of the silicon dioxide is 4mm. The chlorine molar ratio of copper chloride in the pyrolysis catalyst is 1:2 (ie Hg:Cl=1:2);

[0055] The above-mentioned preheated mixture is placed in a rotary furnace, and then the mixed carrier gas is continuously introduced, and an oxygen-controlled pyrolysis reaction (ie, mercury removal reaction) is carried out...

Embodiment 2

[0062] This embodiment provides a mercury removal and regeneration method for a waste copper-based mercury removal adsorbent, the steps of which are as follows:

[0063] The copper sulfide mercury removal adsorbent and the low-temperature pyrolysis catalyst discarded by the power plant with activated carbon as the carrier are mixed and preheated in a stirred reactor. The preheating temperature is 50 ° C and the time is 30 minutes to obtain a preheated mixture; wherein, The above-mentioned low temperature pyrolysis catalyst is composed of 70% copper chloride by mass percentage and 30% silicon dioxide by mass percentage. The particle diameter of the silicon dioxide is 4mm. The chlorine molar ratio of copper chloride in the catalyst is 1:1 (ie Hg:Cl=1:1);

[0064] The above-mentioned preheated mixture is placed in a rotary furnace, and then the mixed carrier gas is continuously introduced, and an oxygen-controlled pyrolysis reaction (ie, mercury removal reaction) is carried out i...

Embodiment 3

[0070] This embodiment provides a mercury removal and regeneration method for a waste copper-based mercury removal adsorbent, the steps of which are as follows:

[0071] Take the abandoned copper sulfide mercury removal adsorbent with aluminum oxide as the carrier and the low-temperature pyrolysis catalyst in a gas field and mix and preheat in a stirred reactor. The preheating temperature is 50°C and the time is 30 minutes to obtain a preheated mixture; Wherein, the above-mentioned low-temperature pyrolysis catalyst is composed of 90% by mass percentage of copper sulfide and 10% by mass of silicon dioxide, and the particle diameter of the silicon dioxide is 4mm. The sulfur molar ratio of copper sulfide in the decomposing catalyst is 1:2 (ie Hg:S=1:2);

[0072]The above-mentioned preheated mixture is placed in a rotary furnace, and then the mixed carrier gas is continuously introduced, and an oxygen-controlled pyrolysis reaction (ie, mercury removal reaction) is carried out in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com