Method for efficiently removing elemental mercury in flue gas

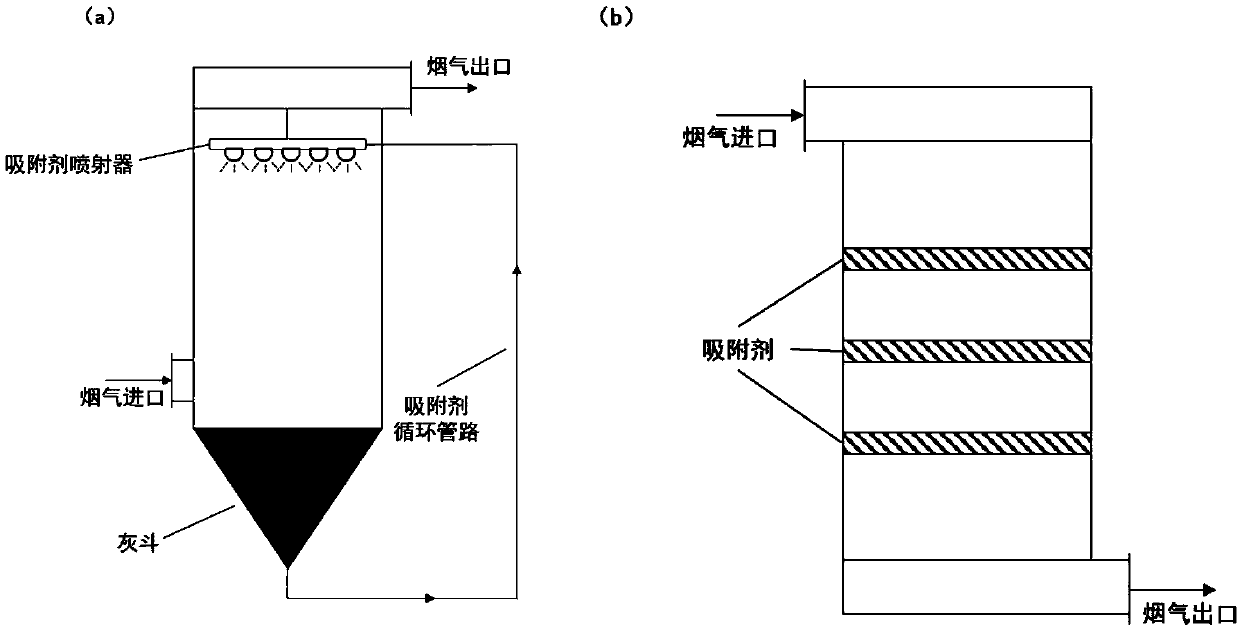

A technology for elemental mercury and flue gas, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problem that commercial activated carbon has a small mercury adsorption capacity and rate, is difficult to remove by flue gas treatment devices, and is difficult to meet mercury emissions. Standard and other issues, to achieve excellent mercury removal effect, reduce mercury re-release, and improve the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 50 mg of natural copper selenium (CuSe), whose BET specific surface area is 0.18 m 2 g -1 , passed through a 100-mesh sieve after drying, and placed in a cylindrical quartz glass fixed-bed reactor with a length of 10 cm and an inner diameter of 1 cm. Mercury produced by mercury permeation tube, Hg 0 Initial concentration 75 μg·m -3 , and use 1 L min -1 Nitrogen acts as the carrier gas through the CuSe adsorbent, and the simulated flue gas flow rate is 0.15m s -1 , use the VM3000 mercury detector to monitor the Hg at the inlet and outlet of the reactor 0 concentration. When the reaction temperature is room temperature, for Hg 0 The adsorption efficiency is 100%.

Embodiment 2

[0031] Weighing synthetic molybdenum selenide (MoSe 3 ) 10 mg, the synthesis method is: mix and dissolve selenium powder and sodium molybdate in 14 v% hydrazine hydrate solution, transfer the solution to the reaction kettle and o Under the condition of C, react for 12 hours, pass through a 100-mesh sieve after centrifugal drying, and the BET specific surface area can reach 101.3 m 2 g -1 . The synthesized MoSe 3 Weigh 10 mg and place it in a cylindrical quartz glass fixed-bed reactor with a length of 10 cm and an inner diameter of 1 cm. Mercury produced by mercury permeation tube, Hg 0 Initial concentration 1000 μg·m -3 , and use 1 L min -1 Nitrogen acts as a carrier gas through MoSe 3 Adsorbent, the simulated flue gas flow rate is 0.5 m s -1 , use the VM3000 mercury detector to monitor the concentration of elemental mercury at the inlet and outlet of the reactor, and the reaction temperature is 50 o C, in the case of flue gas with high mercury content, Hg 0The remo...

Embodiment 3

[0033] Weigh 200 mg of synthetic zinc selenite (ZnSe), the synthesis method is as follows: mix and dissolve zinc sulfate and sodium selenate in equimolar ratio in 10 v% hydrazine hydrate solution, and place in a reaction kettle at 150 o Reaction under C conditions for 12 hours, after centrifugal drying, 100-mesh sieve, its BET specific surface area reached 202 m 2 g -1 . 200 mg of the synthesized ZnSe was weighed and placed in a cylindrical quartz glass fixed-bed reactor with a length of 10 cm and an inner diameter of 1 cm. Hg generation via mercury permeation tube 0 , Hg 0 Initial concentration 60 μg·m -3 , and use 1 L min -1 Nitrogen acts as a carrier gas through the ZnSe adsorbent, while adding simulated flue gas components of 300 ppm NO, 400 ppm SO 2 , 30ppm HCl and 8% H 2 O, use a VM3000 mercury detector to monitor the concentration of elemental mercury at the inlet and outlet of the reactor. The reaction temperature is 200°C, Hg 0 The extraction efficiency reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com