Catalyst for preparing low-carbon mixed alcohol by synthetic gas, its preparation method and application

A low-carbon mixed alcohol and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve problems such as poor stability of anti-sulfur catalysts, and achieve the effect of improving stability and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

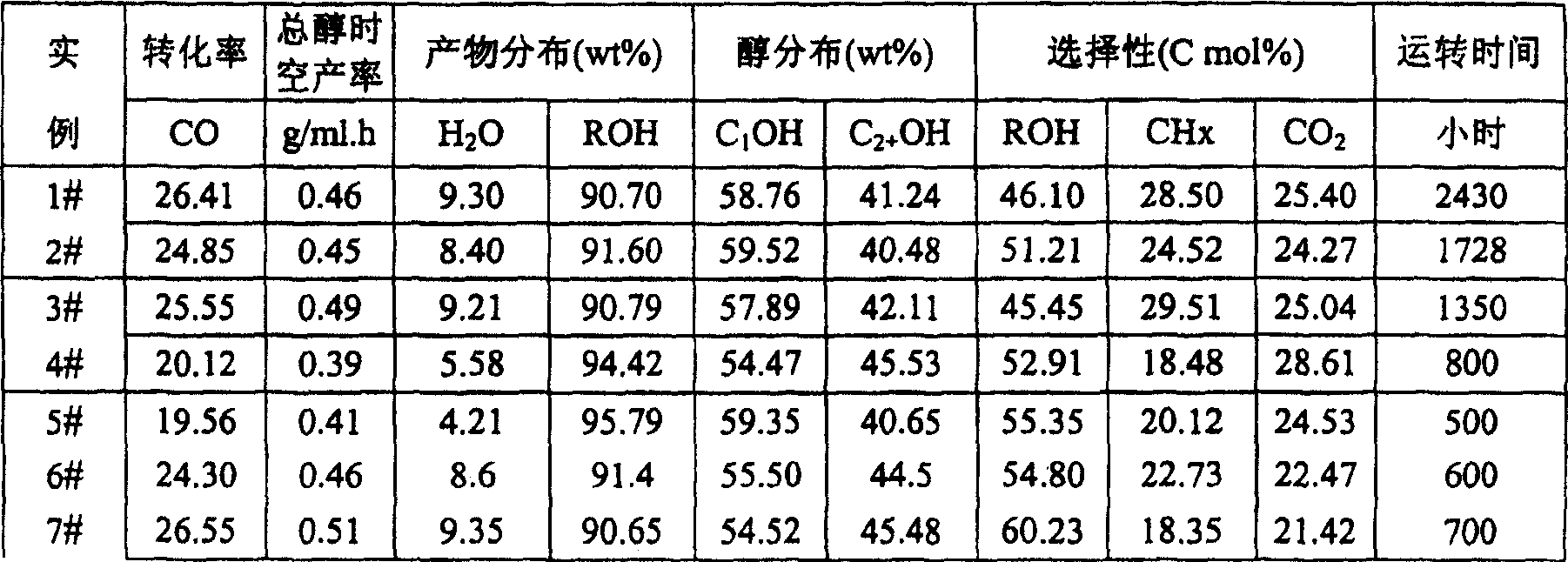

Examples

Embodiment 1

[0034] Ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 .24H 2 O) 13.6g and a concentration of 22% ammonium sulfide ((NH 4 ) 2 S) 120ml of the solution was reacted for one hour at 60°C with stirring, and 50ml of concentrated acetic acid (CH 3 COOH) and deionized water to completely dissolve part of the precipitate and prepare a 1.0M ammonium thiomolybdate solution. Weigh nickel acetate (Ni(CH 3 COO) 2 .4H 2 O) 4.7g, manganese acetate (Mn(CH 3 COO) 2 .4H 2 O) 1.7g was dissolved in 150ml deionized water together, and this solution reacted with ammonium thiomolybdate solution and 300ml concentration of 30% acetic acid solution at 60°C with stirring to generate a black precipitate. Wash, filter, and dry under vacuum at 120°C to obtain a molybdenum-based precipitate. Weigh 1.7g of ferrous sulfide and the same quality of citric acid and mix them thoroughly, rise to 450°C under nitrogen protection, roast at constant temperature for 2 hours, cool to room temperature, fully mix wit...

Embodiment 2

[0036] Ammonium molybdate ((NH 4 ) 6 Mo 7 o 24· 24H 2 O) 13.6g and a concentration of 22% ammonium sulfide ((NH 4 ) 2 S) 120ml of the solution was reacted for one hour at 60°C with stirring, and 50ml of concentrated acetic acid (CH 3 COOH) and deionized water to completely dissolve part of the precipitate and prepare a 0.5M ammonium thiomolybdate solution. Weigh nickel acetate (Ni(CH 3 COO) 2· 4H 2 O) 6.4g, manganese acetate (Mn(CH 3 COO) 2· 4H 2 O) 3.4g were dissolved in 150ml deionized water together, and this solution reacted with ammonium thiomolybdate solution and 300ml concentration of 30% acetic acid solution at 60°C under stirring to generate black precipitate. Wash, filter, and dry under vacuum at 120°C to obtain a molybdenum-based precipitate. Weigh 1.15g of ferrous sulfide and the same quality of citric acid and mix them thoroughly, rise to 450°C under nitrogen protection, roast at constant temperature for 2 hours, cool to room temperature, fully mix wi...

Embodiment 3

[0038] Ammonium molybdate ((NH 4 ) 6 Mo 7 o 24· 24H 2 O) 13.6g and a concentration of 22% ammonium sulfide ((NH 4 ) 2 S) 120ml of the solution was reacted for one hour at 60°C with stirring, and 50ml of concentrated acetic acid (CH 3 COOH) and deionized water to completely dissolve part of the precipitate and prepare a 0.8M ammonium thiomolybdate solution. Weigh nickel acetate (Ni(CH 3 COO) 2· 4H 2 O) 3.2g, manganese acetate (Mn(CH 3 COO) 2· 4H 2 O) 1.7g was dissolved in 150ml deionized water together, and this solution reacted with ammonium thiomolybdate solution and 300ml concentration of 30% acetic acid solution at 60°C under stirring to generate black precipitate. Wash, filter, and dry under vacuum at 120°C to obtain a molybdenum-based precipitate. Weigh 2.3g of ferrous sulfide and the same quality of citric acid and mix them thoroughly, rise to 450°C under nitrogen protection, roast at constant temperature for 2 hours, cool to room temperature, fully mix with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com