Mixed titanate support solid electrolyte multilayer film of solid oxide fuel cell and manufacturing method thereof

A solid oxide and solid electrolyte technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve the problems of reduced activity, difficulty in using low-cost dense electrolyte films, etc., and achieve stable structure, good industrialization prospects, Effect of high electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

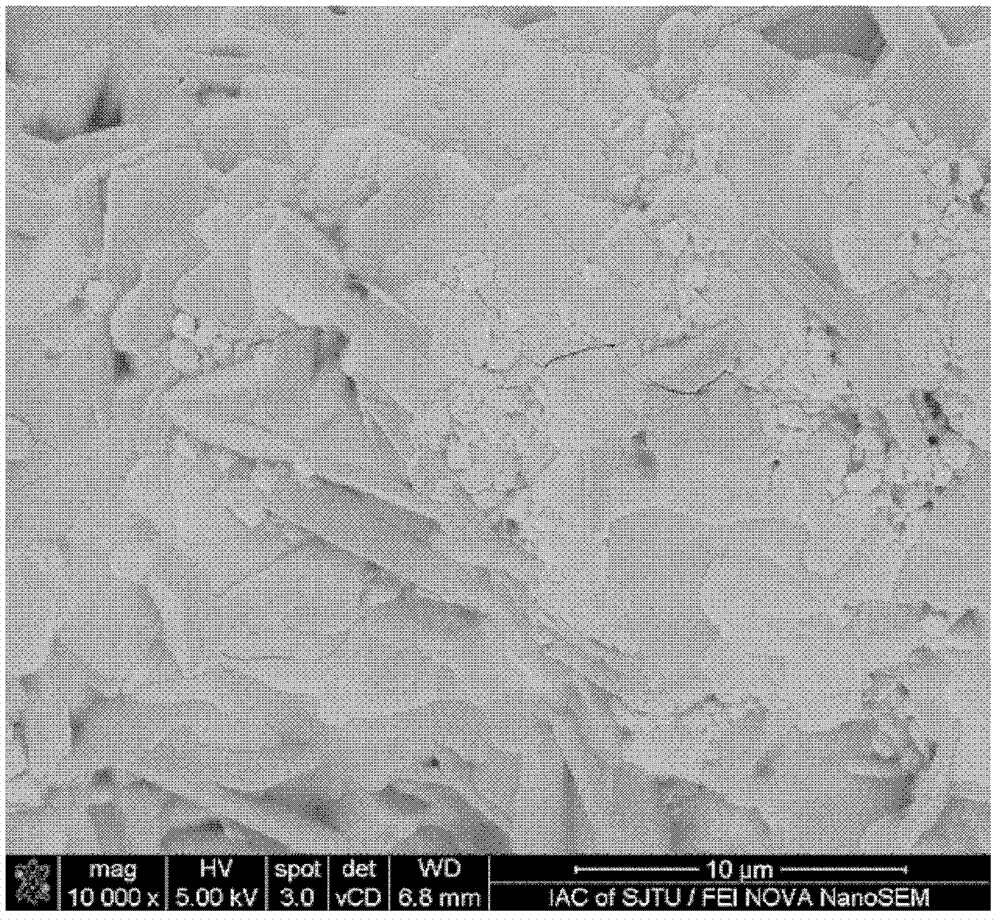

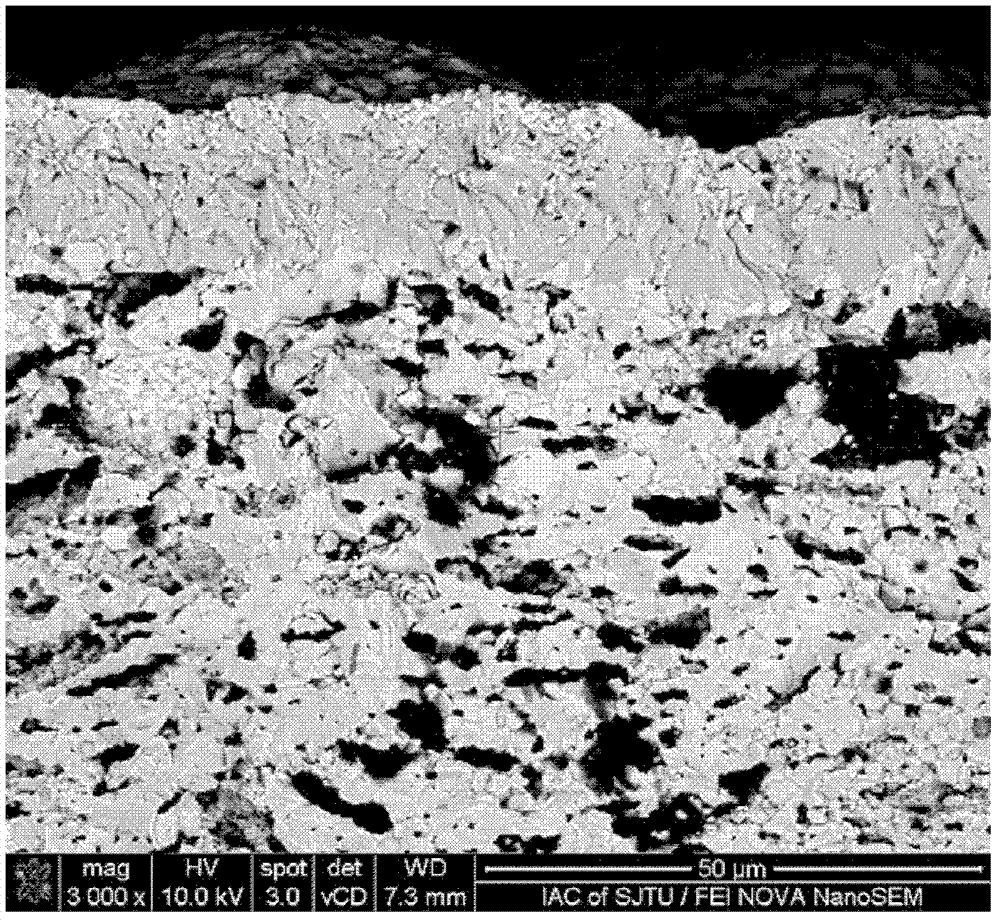

Embodiment 1

[0027] (1) Add 80 grams of La 0.2 Sr 0.7 TiO 3 And 20 grams of starch are added in the ball mill jar, then add 120 grams of butanone and ethanol mixed solvent and 2 grams of triethyl phosphate in a weight ratio of 2: 1, and mix evenly with a planetary ball mill at 300 rpm for 8 hours. Add 18 grams of polyvinyl butyral, 6 grams of dibutyl phthalate and 6 grams of polyethylene glycol 200 to the slurry mixed by ball milling, and then ball mill it with a planetary ball mill at a speed of 300 rpm. Mix well for 16 hours. The above-mentioned last ball-milled slurry was subjected to vacuum degassing treatment for 30 minutes, and cast on a tape casting machine to make La 0.2 Sr 0.7 TiO 3 The support body green body, the thickness of the support body green body after drying is 700 μm.

[0028] (2) ethyl cellulose is dissolved in terpineol, and the ethyl cellulose terpineol solution that makes ethyl cellulose content is 2wt% is applied to transition layer and electrolyte as screen ...

Embodiment 2

[0035] (1) Carry out La according to embodiment 1 0.2 Sr 0.7 TiO 3 Support body green body and ethyl cellulose terpineol solution preparation, and transition layer deposition.

[0036] (2) Add 9 grams of YSZ powder to 27 ml of ethylcellulose terpineol solution, grind for more than 2 hours to obtain a stable and uniform slurry, and deposit the prepared electrolyte slurry evenly on the transition layer to form an electrolyte layer.

[0037] (3) Carry out co-sintering of the support body green body, the transition layer and the electrolyte layer according to Example 1, and prepare a doped titanate-supported solid electrolyte multilayer membrane.

Embodiment 3

[0039] (1) Add 60 grams of La 0.2 Sr 0.7 TiO 3 , 20g Al 2 o 3 Add the powder and 20 grams of starch into the ball mill jar, then add 120 grams of methyl ethyl ketone and ethanol mixed solvent and 2 grams of triethyl phosphate in a weight ratio of 2:1, and use a planetary ball mill to mix evenly at 300 rpm for 8 hours. Add 18 grams of polyvinyl butyral, 6 grams of dibutyl phthalate and 6 grams of polyethylene glycol 200 to the slurry mixed by ball milling, and then ball mill it with a planetary ball mill at a speed of 300 rpm. Mix well for 16 hours. The above-mentioned last ball-milled slurry was subjected to vacuum degassing treatment for 30 minutes, and cast on a tape casting machine to make La 0.2 Sr 0.7 TiO 3 The support body green body, the thickness of the support body green body after drying is 700 μm.

[0040] (2) Preparation of ethylcellulose terpineol solution, transition layer and electrolyte layer deposition according to Example 1.

[0041] (3) Carry out co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com