Carbon fiber hydrogen storage material, and preparation method thereof

A hydrogen storage material, carbon fiber technology, applied in the direction of fiber chemical characteristics, chemical instruments and methods, hydrogen, etc., can solve the problems of poor flexibility of carbon fiber, limited hydrogen storage capacity, low specific surface area, etc., and achieve good toughness and good regeneration performance , the effect of high average molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

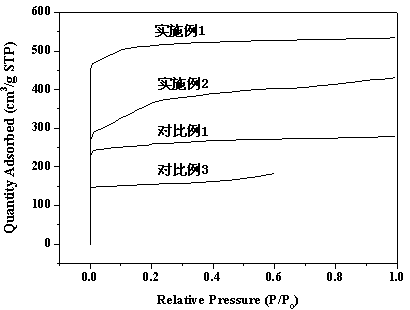

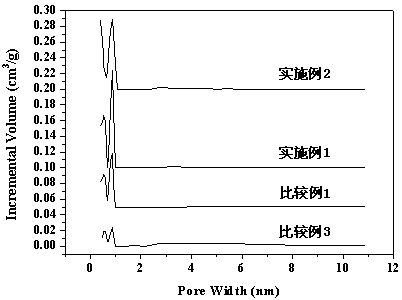

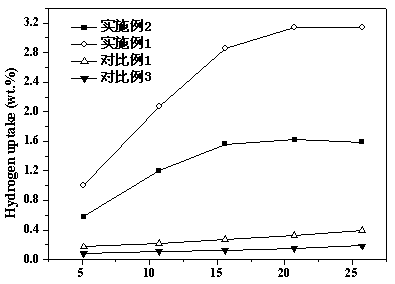

Image

Examples

Embodiment 1

[0033] Take 20 g of rice straw, cut into small pieces of about 8 cm, and soak in 2000 g of 20% sodium hydroxide solution at room temperature for 24 hours. Weigh 10 g of soaked rice straw and place it in a mixed solution of N-methylmorpholine-N-oxide / deionized water / propyl gallate, N-methylmorpholine-N-oxide / deionized water The mass of propyl gallate is 50g, 10g and 1g respectively, and the magnetic water bath is turned on to stir, and the treatment is carried out at 100°C and 200rpm for 10h. The obtained dark yellow solution was poured into a spinning vessel, and purged with nitrogen gas at 20 mL / min to make the solution pass through a 0.1 mm spinneret. Then the spinning solution is extruded through the spinneret at 100°C, enters the deionized water coagulant bath after 50min, and is stretched by the winding shaft, and then the elongated fiber is removed from the coagulant at a speed of 10m / min bath. After winding, the filaments on the spool are soaked in deionized water for...

Embodiment 2

[0036] In Example 1, the carbon fiber hydrogen storage material B was obtained by replacing the rice straw with wooden branches of the same mass, and keeping other reaction conditions and material composition unchanged.

Embodiment 3

[0038] In Example 1, the sodium hydroxide solution was replaced with lithium hydroxide solution of the same amount and concentration, and other reaction conditions and material composition remained unchanged to obtain carbon fiber hydrogen storage material C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com