Preparation process of renewable sulfur-resistant Fe-Mn-Ce magnetic adsorbent for flue gas demercuration

A magnetic adsorbent, fe-mn-ce technology, applied in gas treatment, alkali metal oxide/hydroxide, inorganic chemistry, etc. It can improve the anti-SO2 poisoning performance, protect the active site of mercury removal, and reduce the toxic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 8.1 g ferric chloride hexahydrate (FeCl 3 ·6H 2 O), 8.34g ferrous sulfate (FeSO 4 ·7H 2 O), 0.338g manganese sulfate (MnSO 4 ·H 2 O) and 3.427g cerium nitrate (Ce(NO3 ) 3 ·6H 2 0) for subsequent use; measure 200ml of deionized water with a graduated cylinder and place it in a beaker, add the weighed medicine to the deionized water and stir until there is no obvious fine particle, and make a mixed solution A;

[0039] Measure 100ml ammonia water (NH 3 ·H 2 O) The solution is slowly added to the mixed solution A until PH=8~9 (tested by a pH meter), stirred for 2 hours with an electromagnetic stirrer, and the rotating speed is set at 800r / min, to obtain a sufficient amount of product precipitation, and stand for 12 hours to make the product Precipitation is complete;

[0040] Filter the liquid in the beaker to obtain the reaction product, wash the obtained reaction product with deionized water, and remove the ammonium ion on it until the pH is neutral;

[0...

Embodiment 2

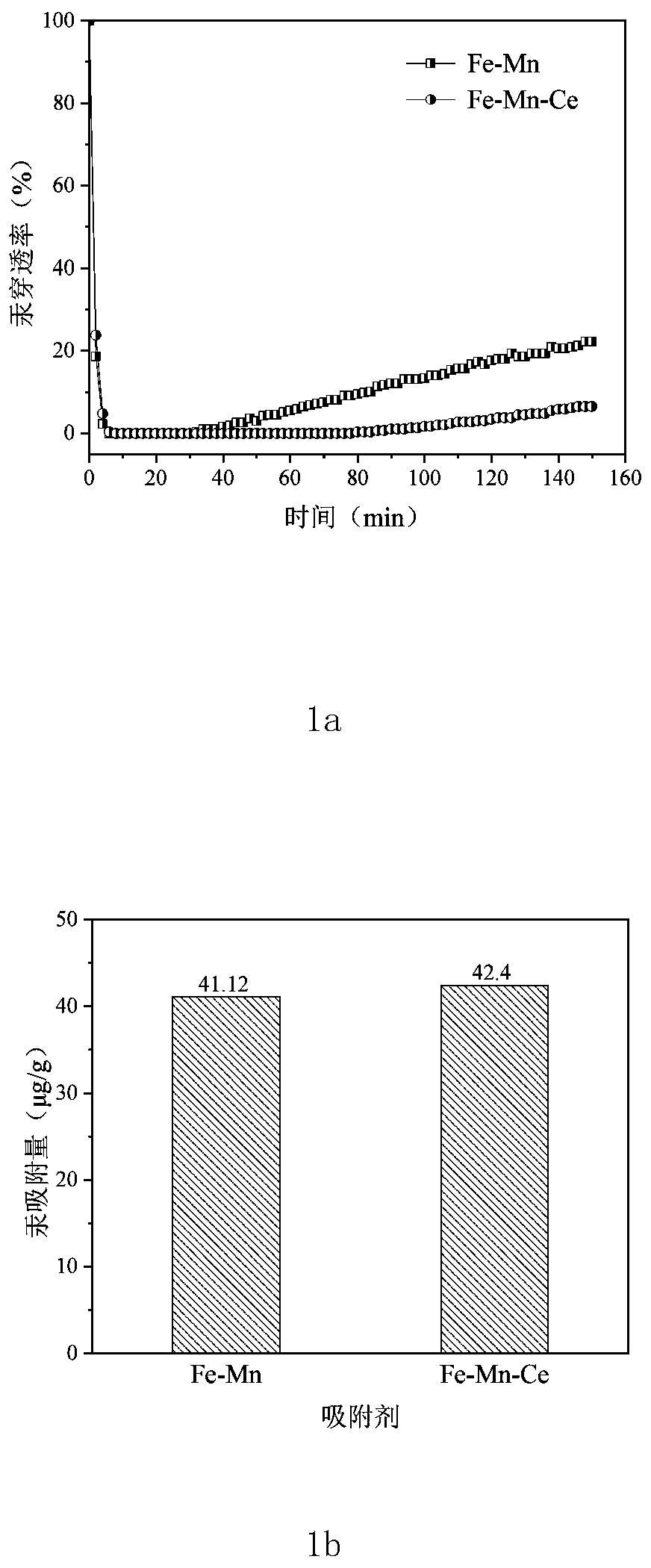

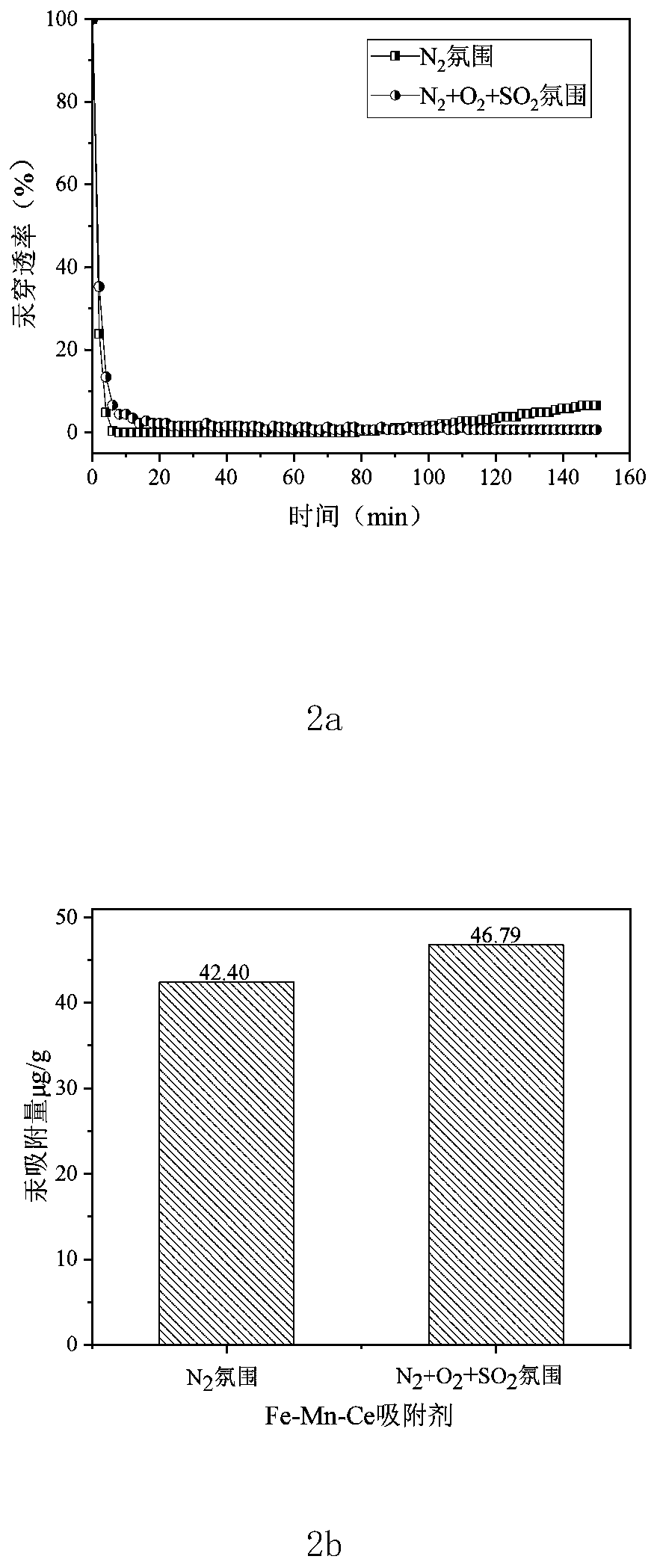

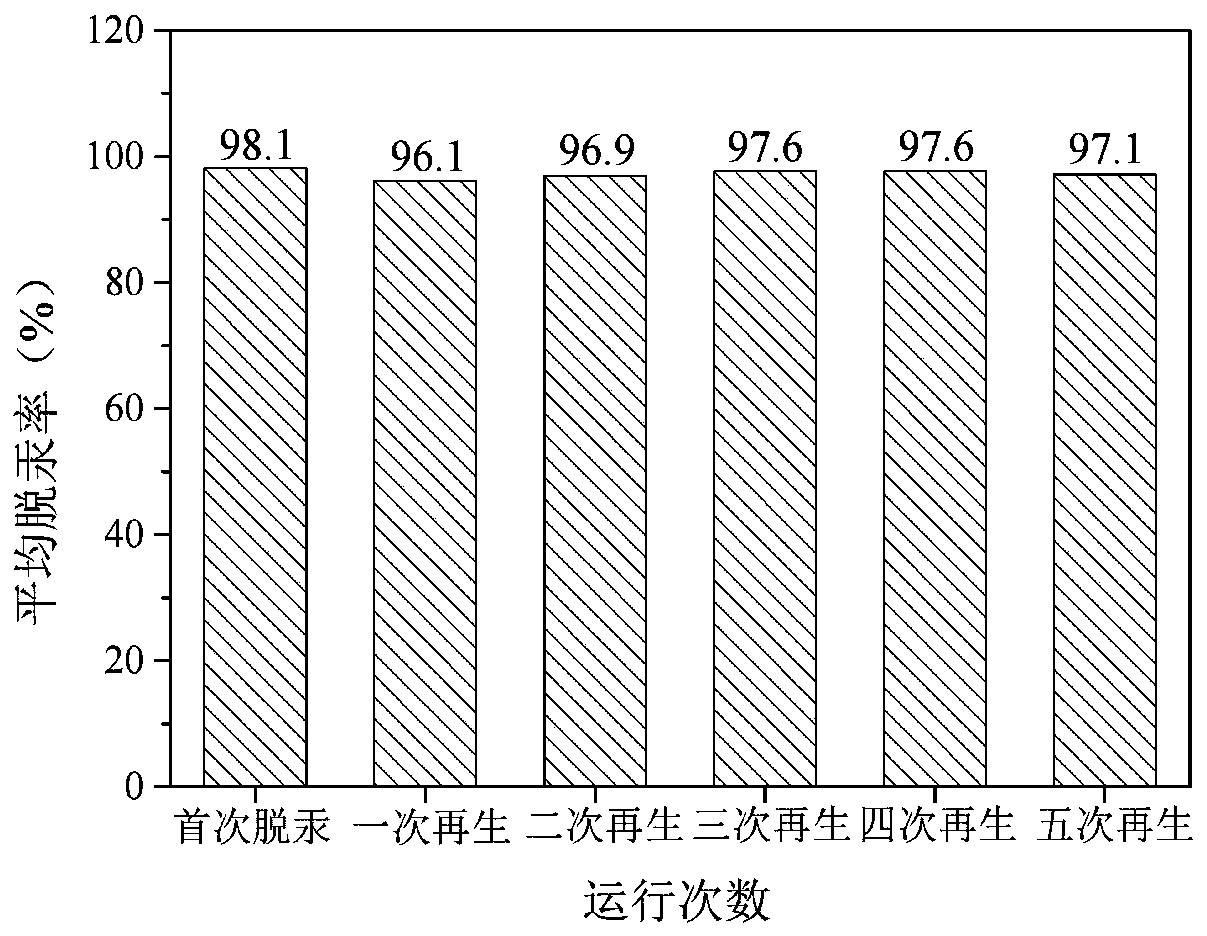

[0044] The regenerable anti-sulfur Fe-Mn-Ce magnetic adsorbent for flue gas demercuration was prepared by the above-mentioned Example 1, and its mercury removal and regeneration effect was verified on the fixed bed adsorption performance testing experimental device;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com