120ksi primary grade sulfur-resistant drill pipe and manufacturing method thereof

A manufacturing method and drill pipe technology, applied in the manufacture of tools, furnace types, furnaces, etc., can solve the problems of low oil and gas production, sulfide stress corrosion cracking, and low strength of sulfur-resistant drill pipes, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

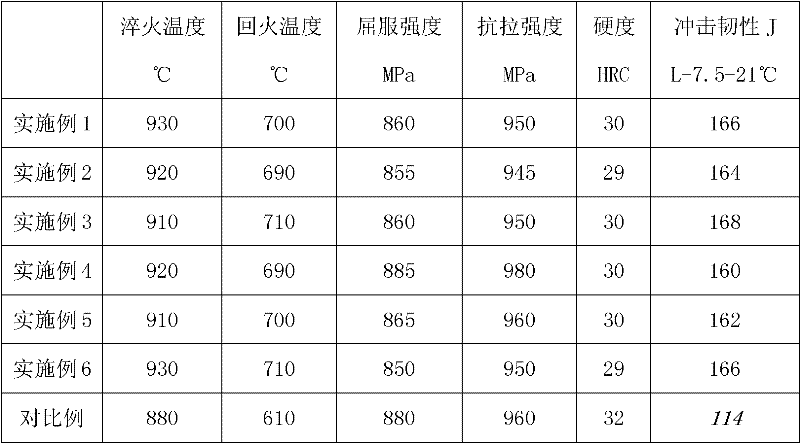

Embodiment 1-6

[0056] Adopt the following steps to prepare the primary sulfur-resistant drill pipe of 120ksi steel grade (the various steel grade compositions of this case embodiment 1-6 and comparative example are shown in Table 1, and wherein comparative example is the commonly used CrMnMo steel drill pipe of prior art):

[0057] (1) Thickening the pipe end to make a pipe body of a thickened drill pipe;

[0058] (2) Quenching: After heating the drill pipe as a whole to 900-950°C, place it on a rotating quenching stand. While the drill pipe is rotating, the inner surface of the drill pipe is cooled by spraying water on the inner surface of the drill pipe and the outer surface of the drill pipe is cooled by laminar flow. Water spray cooling, while controlling the amount of water sprayed at the thickened pipe end of the drill pipe to be different from that of the pipe body so that the pipe body and the thickened pipe end with different wall thicknesses have the same cooling rate;

[0059] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com