Preparation method, catalyst and application of polycyclic aromatic hydrocarbon hydrogenation catalyst

A hydrogenation catalyst, polycyclic aromatic hydrocarbon technology, applied in chemical instruments and methods, physical/chemical process catalysts, molybdenum sulfide, etc. The problem of high conversion depth, to achieve the effect of high hydrodesulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Catalyst preparation:

[0026] Prepare aqueous solution A containing ammonium tetrathiomolybdate (ATTM), the concentration of ATTM is 0.15mol / L. Prepare aqueous solution B containing hydrazine hydrate, the concentration of hydrazine hydrate is 16mol / L. A mixture C containing nonionic surfactant, n-hexanol and cyclohexane was prepared, wherein the nonionic surfactant was 10.6 g, n-hexanol was 8.0 g and cyclohexane was 13.3 g. Add 4ml of ATTM aqueous solution A to mixture C under stirring, and stir for 30 minutes to obtain stable microemulsion D. Add 1 ml of hydrazine hydrate aqueous solution B to the above microemulsion D, and stir for 30 minutes to obtain stable microemulsion E. The microemulsion E was transferred into an autoclave, sealed and left to crystallize at 185°C for 24 hours. Cool down to room temperature naturally after taking it out. After filtering, washing with deionized water and absolute ethanol three times, and vacuum drying at 70 °C for 12 h, the b...

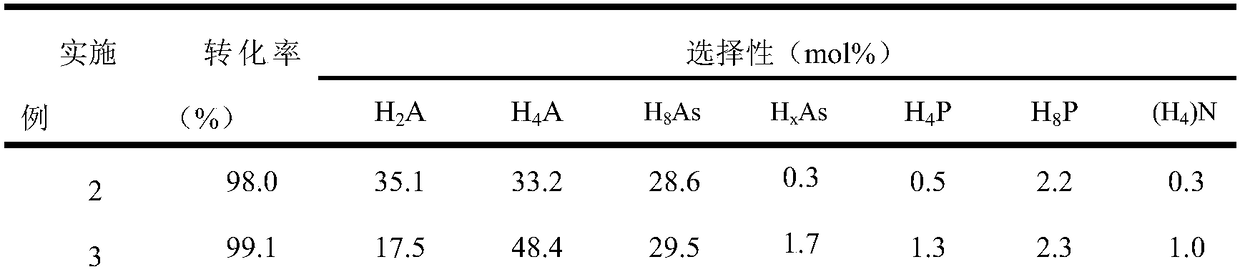

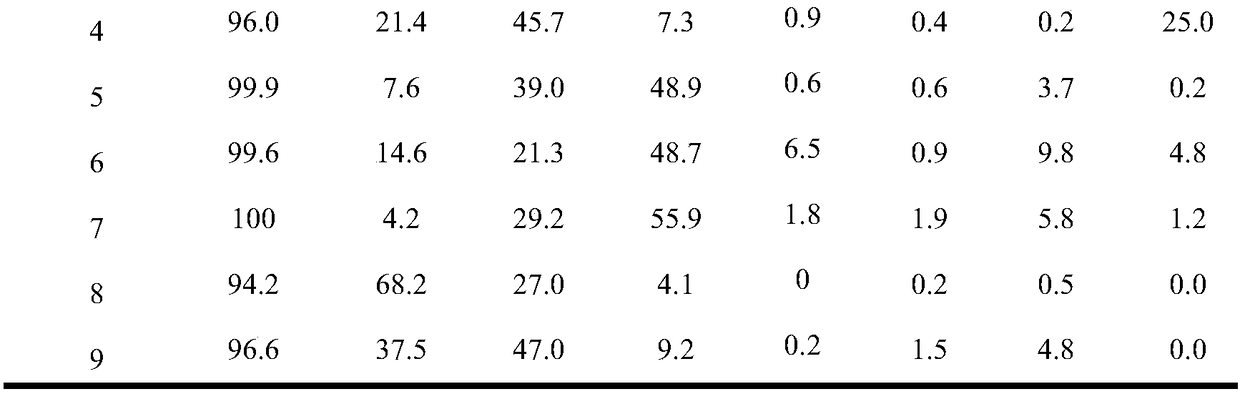

Embodiment 2

[0029] Add 0.075g of the molybdenum disulfide catalyst prepared in Example 1 (5% by weight based on anthracene) into the 100mL autoclave reactor of the slurry bed reaction system, and then add 1.5g of anthracene and 28.5g of n-hexadecane. After loading the kettle, replace the air with hydrogen 3 times (close the exhaust valve first, then open the intake valve each time, pressurize with 100ml / min hydrogen to 2MPa, then close the intake valve, and then open the exhaust valve to empty.), boost the pressure to 4MPa, then raise the temperature to 325°C, and carry out the hydrogenation reaction at a stirring speed of 300r / min for 4 hours.

Embodiment 3

[0031] Add 0.075g of the molybdenum disulfide catalyst prepared in Example 1 (5% by weight based on anthracene) into the 100mL autoclave reactor of the slurry bed reaction system, and then add 1.5g of anthracene and 28.5g of n-hexadecane. After filling the kettle, replace the air with hydrogen for 3 times (the replacement operation is the same as in Example 2), increase the pressure to 4MPa, and then raise the temperature to 350°C, and carry out the hydrogenation reaction for 4 hours at a stirring speed of 300r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com