Preparation process of renewable sulfur-resistant fe-mn-ce magnetic adsorbent for mercury removal from flue gas

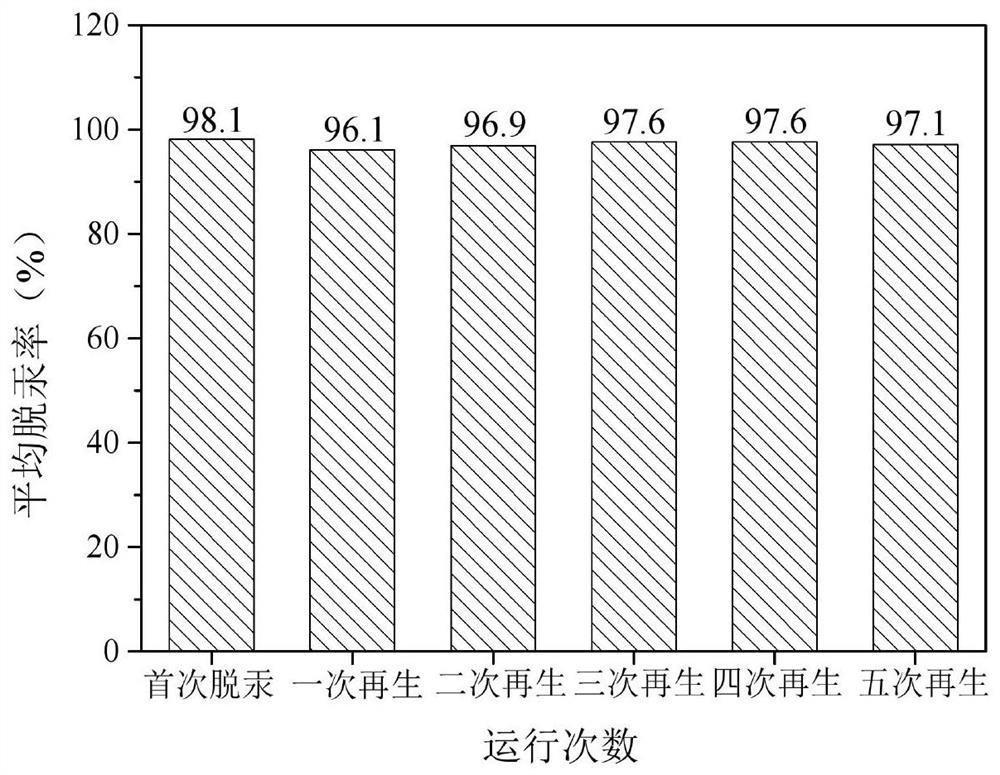

A magnetic adsorbent, fe-mn-ce technology, applied in gas treatment, other chemical processes, separation methods, etc., can solve the problems of inability to restore to the original state, difficult recovery and reuse of adsorbents, secondary pollution, etc. Achieve the effect of improving anti-SO2 poisoning performance, protecting active sites for mercury removal, and realizing recycling

Active Publication Date: 2022-06-03

NANJING NORMAL UNIVERSITY

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

my country's coal-fired power plant flue gas mercury removal technology is mainly developing in two directions: one is to develop a new selective catalytic reduction (SCR) catalyst to achieve combined denitrification and mercury removal, but the Hg of the SCR catalyst 0 Oxidation performance is related to the chlorine content in the flue gas, and the use of SCR catalysts to remove mercury has certain limitations; the other direction is activated carbon injection (ACI), but ACI technology also has carbon-based adsorbents that are difficult to remove from fly ash after adsorbing mercury. The problem of separating out in the process leads to difficult recovery and reuse of the adsorbent, high cost, and low utilization rate; more importantly, the synergistic demercury removal of the SCR catalyst and the mercury removal by the ACI technology will decompose the more toxic HgCl 2 Introduced into coal combustion by-products (fly ash and desulfurization gypsum), and coal combustion by-products in my country are used for secondary use. After leaching or high temperature process, mercury in coal combustion by-products will be released again, causing secondary pollution

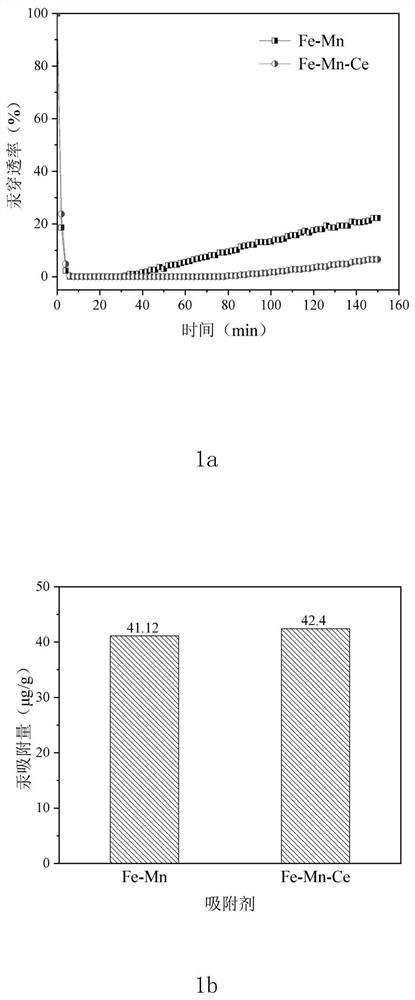

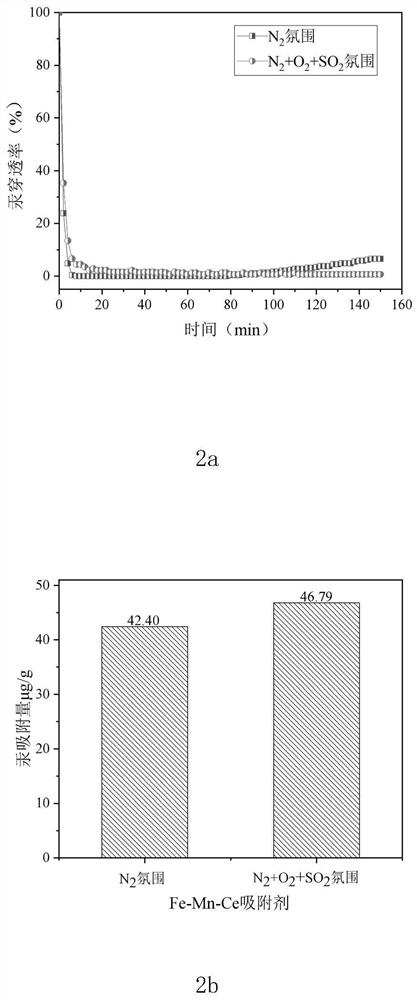

[0004] At present, iron-manganese (Fe-Mn) magnetic adsorbent has received extensive attention due to its advantages of recyclability, regeneration, low cost, and high activity, and is generally considered to have a good application prospect. However, Fe-Mn magnetic adsorbent Prone to SO 2 Poisoning defects limit its industrial application; a certain concentration of SO in coal-fired flue gas 2 It will lead to poisoning and inactivation of Fe-Mn magnetic adsorbent, especially when H 2 When O exists at the same time, SO 2 The poisoning is more serious, which will not only reduce its ability to remove mercury, but may even cause it to fail to return to its original state after regeneration, making the mercury adsorption capacity permanently damaged; therefore, Fe-Mn magnetic adsorbents can be modified with transition metals , to enhance its resistance to SO 2 Poisoning ability and mercury removal performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a preparation process of a renewable anti-sulfur Fe-Mn-Ce magnetic adsorbent for flue gas demercuration. A high-efficiency mercury removal adsorbent for mercury technology, with strong mercury removal performance, magnetic separation, renewability, and anti-SO 2 Poisoning and other advantages, can achieve efficient mercury removal and recycling of coal-fired flue gas.

Description

Preparation of Renewable Sulfur-Resistant Fe-Mn-Ce Magnetic Adsorbent for Flue Gas Removal of Mercury craft technical field The present invention relates to a kind of preparation technology of the regenerable anti-sulfur type Fe-Mn-Ce magnetic adsorbent for flue gas demercuring, It belongs to the field of mercury removal from coal-fired flue gas. Background technique Heavy metal mercury is a kind of pollutant that is extremely harmful to the ecological environment and human health and is highly toxic, and has The characteristics of inter-regional migration, biological accumulation, food chain toxicity transmission, strong latent and other characteristics are mainly derived from natural discharge, human In terms of emissions and secondary releases, in addition to natural causes, fossil fuel combustion, metal smelting, cement production, chlor-alkali industry, Human activities such as municipal actions have increasingly become an important source of mercury pollution...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J20/02B01J20/28B01J20/30B01D53/02

CPCB01J20/0229B01J20/0222B01J20/28009B01D53/02B01D2258/0283B01D2257/602

Inventor 周强尚瑜陶信狄冠丞姜鑫王永琪卢平

Owner NANJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com