Vanadium-doped OMS-2 loaded TiO2 material as well as preparation method and application thereof

A technology of OMS-2 and V-OMS-2, applied in the field of CO reduction low-temperature denitrification catalyst V-OMS-2@TiO2 material and its preparation, can solve the problems of narrow activation temperature window and poor low temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

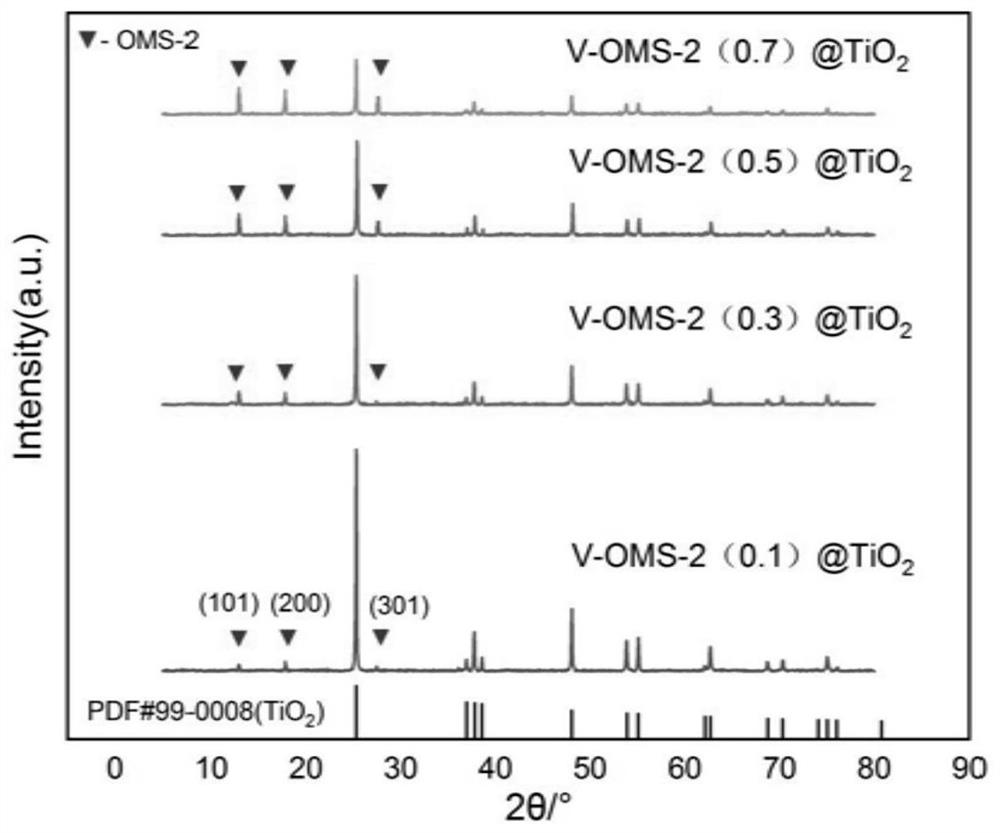

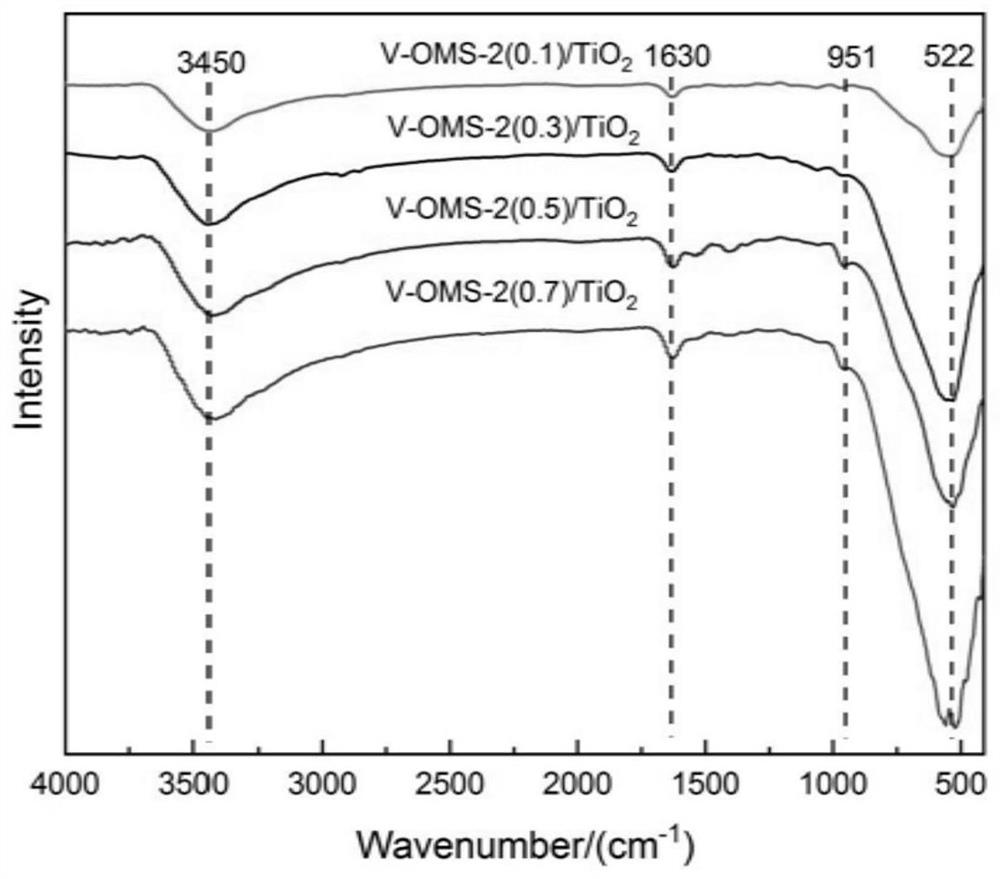

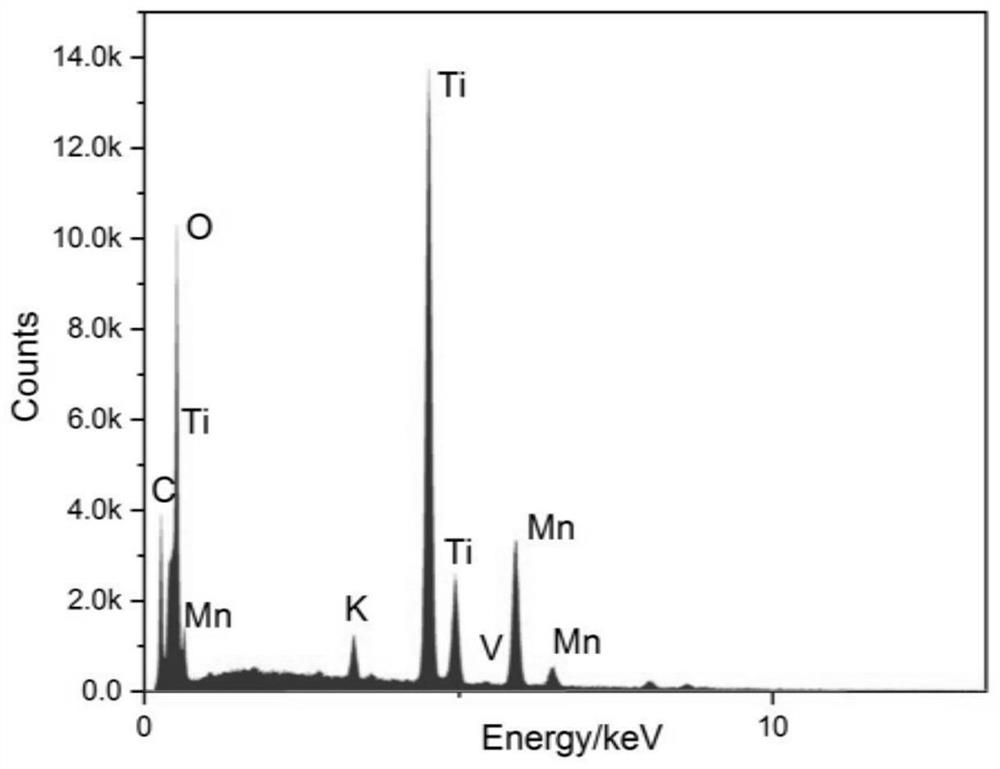

[0036] First, 1.5g of anatase TiO 2 Disperse in 30ml of deionized water to form solution A, take 0.32g of manganese acetate and 0.07g of sodium orthovanadate dissolved in 30ml of deionized water to form solution B, take 0.24g of potassium permanganate and dissolve in 30ml of deionized water to form For solution C, slowly pour solutions A and B into the polytetrafluoroethylene lining, then slowly pour solution C while stirring, seal the reaction vessel after stirring evenly, and put it in an oven at 120°C for 4 hours. The product obtained after the reaction was washed with deionized water and absolute ethanol and then centrifuged. The black product obtained by centrifugation was dried in an oven for 12 hours and then ground to obtain V-OMS-2(0.1)@TiO 2 sample.

[0037] Place 1g of catalyst in the center of a high-temperature-resistant quartz glass tube, and fix both sides of the catalyst with high-temperature quartz wool. The inner diameter of the quartz glass tube is 12mm and...

Embodiment 2

[0039] First, 1.5g of anatase TiO 2 Disperse in 30ml of deionized water to form solution A, take 0.97g of manganese acetate and 0.21g of sodium orthovanadate dissolved in 30ml of deionized water to form solution B, take 0.72g of potassium permanganate and dissolve in 30ml of deionized water to form For solution C, slowly pour solutions A and B into the polytetrafluoroethylene lining, then slowly pour solution C while stirring, seal the reaction vessel after stirring evenly, and put it in an oven at 120°C for 4 hours. The product obtained after the reaction was washed with deionized water and absolute ethanol and then centrifuged. The black product obtained by centrifugation was dried in an oven for 12 hours and then ground to obtain V-OMS-2(0.3)@TiO 2 sample.

[0040] Place 1g of catalyst in the center of a high-temperature-resistant quartz glass tube, and fix the catalyst with high-temperature quartz wool on both sides. The temperature of the tubular resistance furnace is co...

Embodiment 3

[0042] First, 1.5g of anatase TiO 2 Disperse in 30ml of deionized water to form solution A, take 1.62g of manganese acetate and 0.35g of sodium orthovanadate dissolved in 30ml of deionized water to form solution B, take 1.19g of potassium permanganate and dissolve in 30ml of deionized water to form For solution C, slowly pour solutions A and B into the polytetrafluoroethylene lining, then slowly pour solution C while stirring, seal the reaction vessel after stirring evenly, and put it in an oven at 120°C for 4 hours. The product obtained after the reaction was washed with deionized water and absolute ethanol and then centrifuged. The black product obtained by centrifugation was dried in an oven for 12 hours and then ground to obtain V-OMS-2(0.5)@TiO 2 sample.

[0043] Place 1g of catalyst in the center of a high-temperature-resistant quartz glass tube, and fix the catalyst with high-temperature quartz wool on both sides. The temperature of the tubular resistance furnace is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com