Molybdenum-based catalyst for preparing low-carbon alcohol from synthesis gas by taking alkaline carrier material mesoporous NiO-Al2O3 as carrier and preparation method of molybdenum-based catalyst

A molybdenum-based catalyst, mos2-nio-al2o3 technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. problem, to achieve the effect of non-carbonized operation stability and narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

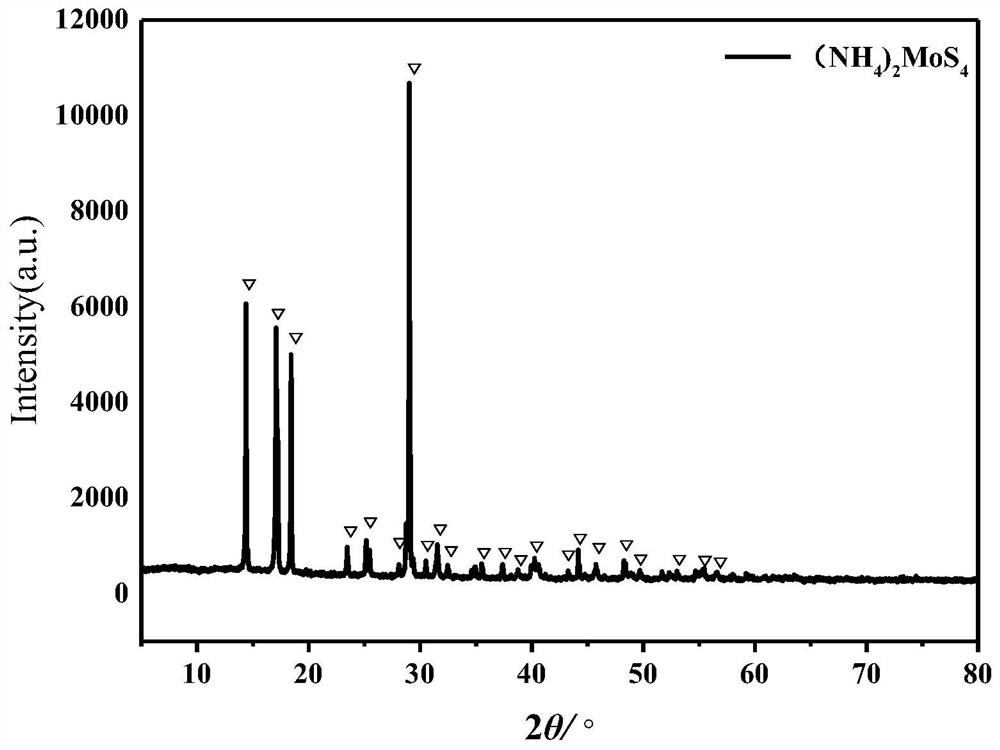

[0031] (1) Basic carrier material mesoporous NiO-Al 2 o 3

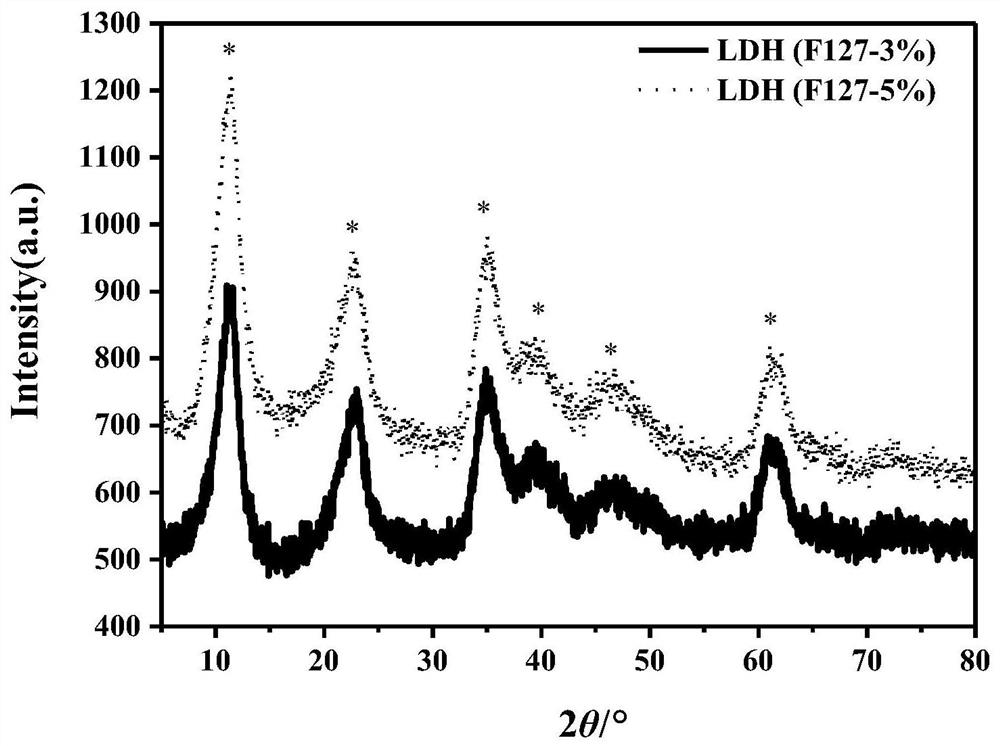

[0032] Synthesis of Ordered Mesoporous Metal Oxide NiO-Al by Soft Template Method 2 The precursor of O NiAl-LDH (NiAl double metal layered hydroxide): add Ni(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and template agent P123 / F127 (see Table 1 for the amount of material added), vigorously stirred at room temperature (stirring time 1 hour, rotating speed 250rpm). The final reaction mixture was adjusted to a pH value of 10.0 with sodium hydroxide solution (concentration of 1 mol / L), and the obtained precipitate was filtered, washed and dried (washed several times with distilled water until the pH of the filtrate was 7, and then the washed precipitate was placed in Drying under vacuum at 60°C for 12 hours) to obtain NiAl-LDH;

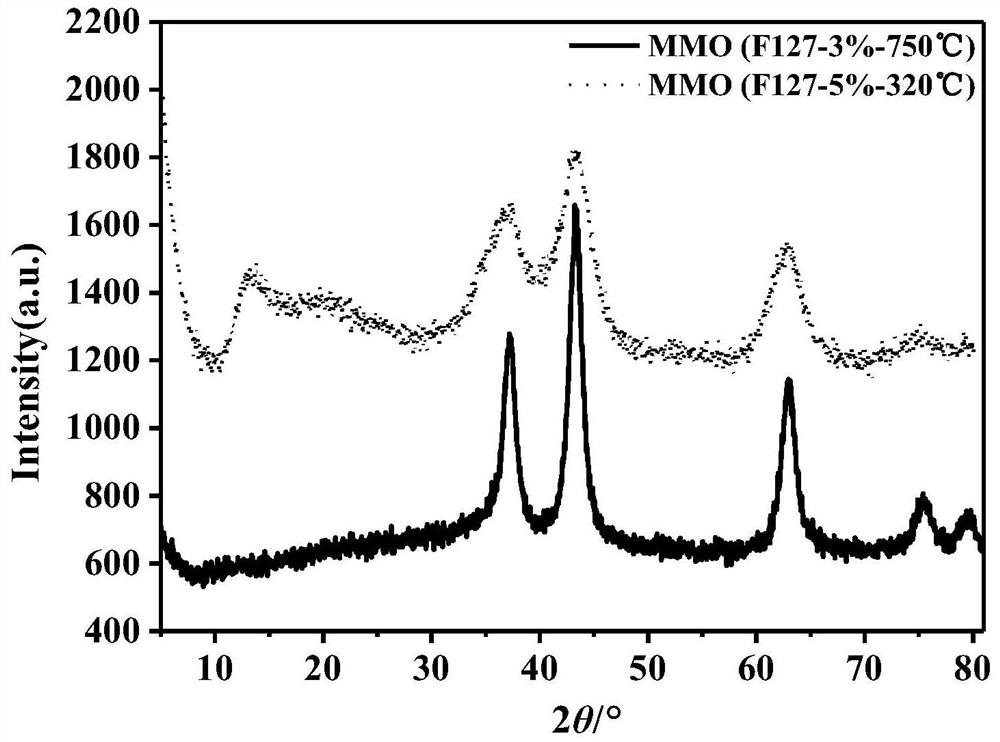

[0033] Then NiAl-LDH is calcined in a muffle furnace with temperature programming (calcination in a muffle furnace, set to increase 5°C per minute, and the calcination time is 5 hours. The obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com