Catalyst for deep purification and removal of impurities in olefin stream at room temperature and its preparation and application

A deep purification and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of poor processing ability of high CO concentration samples and liquid phase polymerization process Inapplicable, complicated process, etc., to achieve the effect of maintaining high activity, good water resistance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of Cobalt-Zinc-Cerium-Based Catalyst Precursor

[0046] Prepare the nitrates of Co, Zn, and Ce metals into a solution of a certain concentration, and mix them evenly under sufficient stirring; the molar ratio of the nitrate solution and the alkali solution is 1:1.5; Co-precipitate with alkali solution under stirring, the precipitation temperature is 60-80°C; after the precipitation is completed, adjust the pH value of the system to 6-7; age the obtained catalyst precursor at a certain temperature, and fully stir; take out the solid product, After repeated washing and centrifugation with deionized water at a certain temperature, place in a drying oven to dry at 80-120°C for 12 hours; roast at 300-500°C for 6.0 hours, and cool to room temperature to obtain the cobalt-zinc-cerium-based catalyst product;

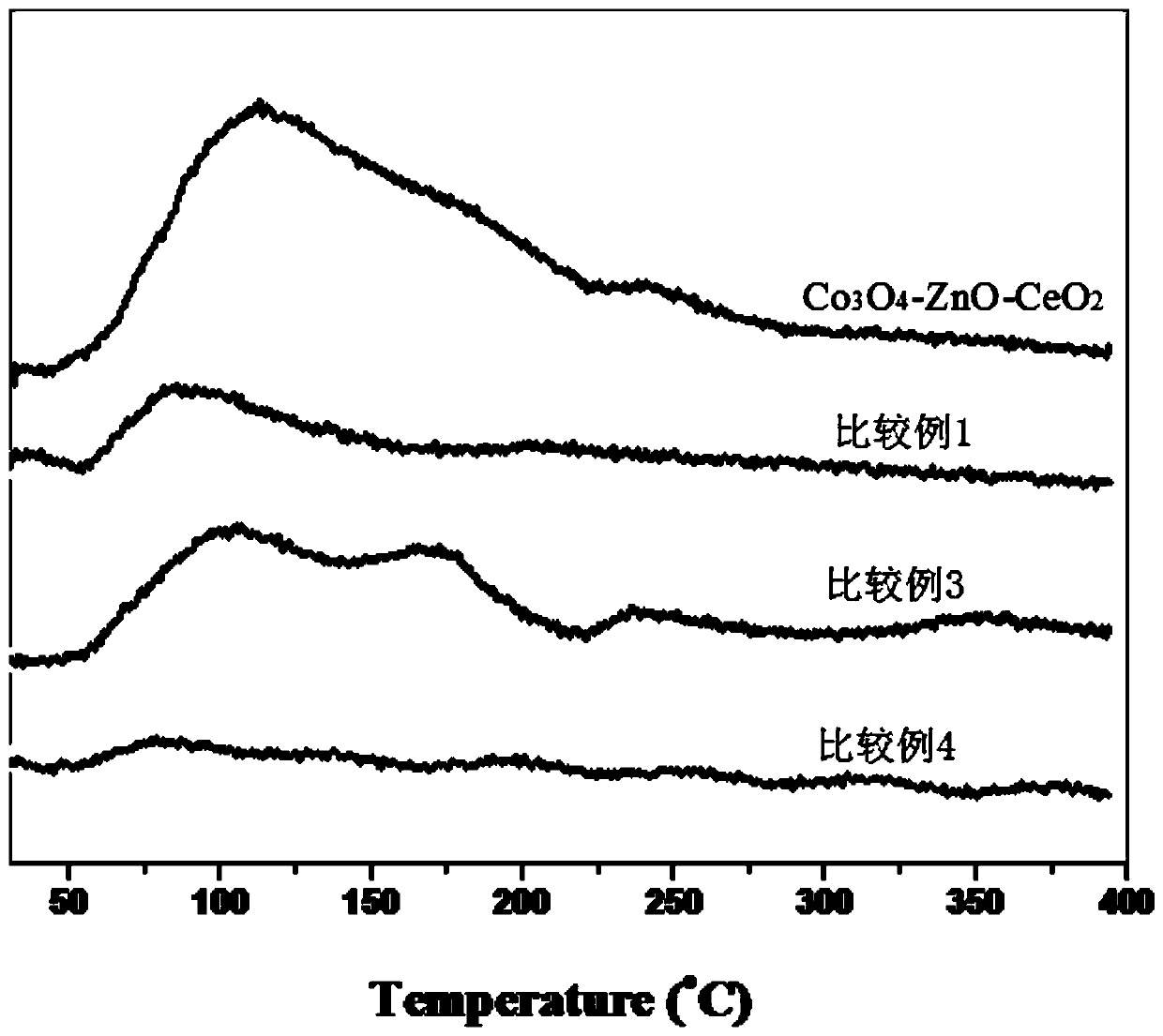

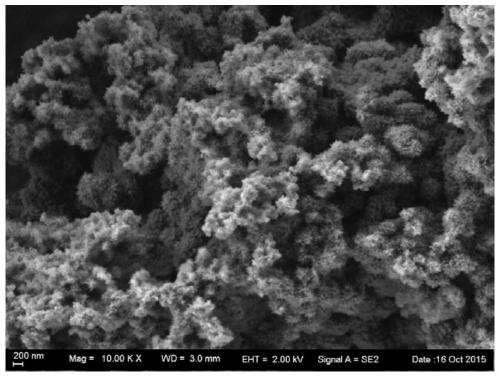

[0047] Depend on figure 2 It can be seen from the SEM image that the nano-cobalt-zinc-cerium composite metal oxide (Co 3 o 4 -ZnO-CeO 2 ) The catalyst ha...

Embodiment 2~5

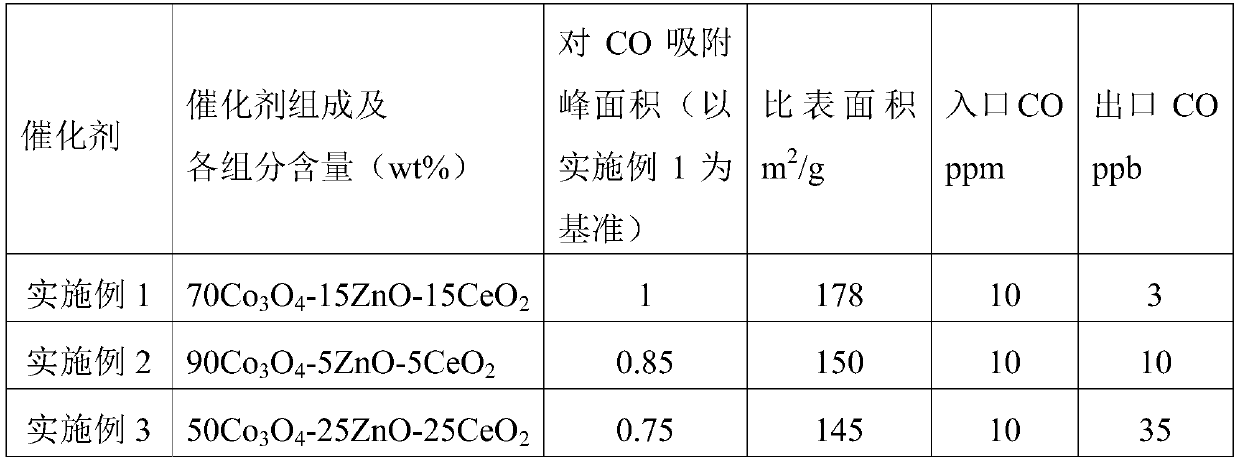

[0057] Using different Co 3 o 4 :ZnO:CeO 2 Proportioning, raw materials are weighed, in weight percentage, see Table 1 for details.

[0058] Prepare the nitrates of Co, Zn, and Ce metals into a solution of a certain concentration, and mix them evenly under sufficient stirring; the molar ratio of the nitrate solution and the alkali solution is 1:1.5; Co-precipitate with alkali solution under stirring, the precipitation temperature is 60-80°C; after the precipitation is completed, adjust the pH value of the system to 6-7; age the obtained catalyst precursor at a certain temperature, and fully stir; take out the solid product, After repeated washing and centrifugation with deionized water at a certain temperature, place in a drying oven to dry at 80-120°C for 12 hours; roast at 300-400°C for 6.0 hours, and cool to room temperature to obtain the cobalt-zinc-cerium-based catalyst product;

[0059] oxidative activation pretreatment

[0060] The catalysts prepared above (Examples...

Embodiment 6

[0062] The cobalt-zinc-cerium-based catalyst prepared in Example 1 was granulated, tabletted, and crushed, and the catalyst particles with a mesh size of 60 to 80 were screened out for an activity test without oxidative activation, which was designated as Example 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com