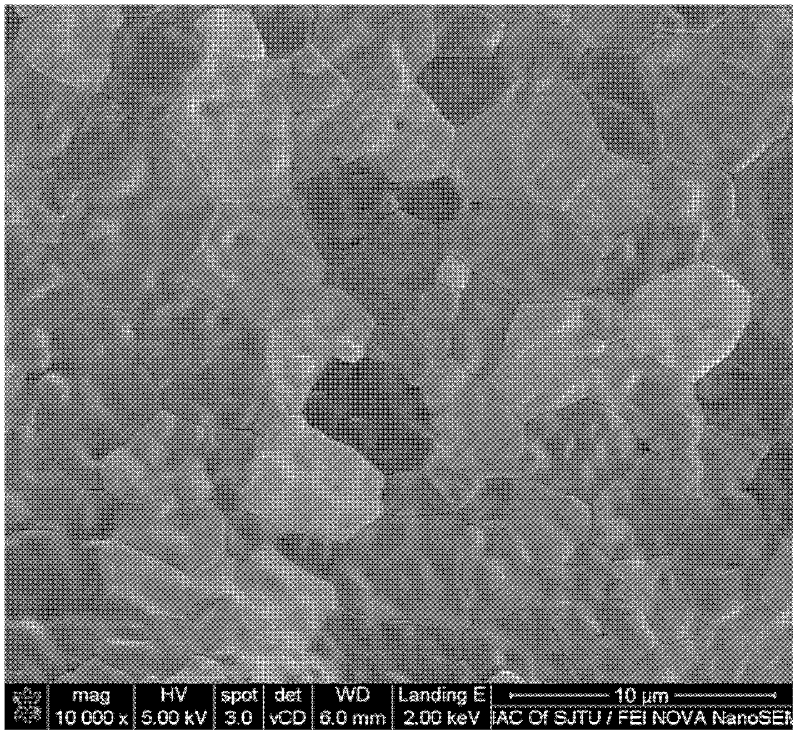

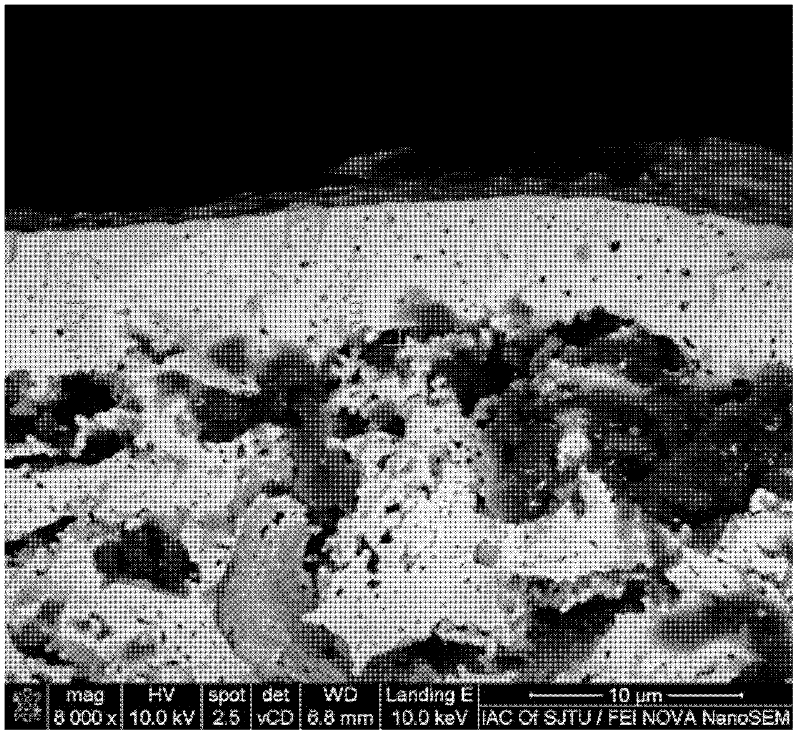

Solid oxide fuel cell anode/electrolyte bilayer membrane and preparation method thereof

A solid oxide and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as the difficulty in preparing dense electrolytes, and achieve good industrialization prospects and stable structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029](1) 80 grams of YSZ and 20 grams of starch are added in the ball mill tank, then add 90 grams of butanone and ethanol mixed solvent and 2 grams of triethyl phosphate in a weight ratio of 2: 1, and ball mill 8 with a planetary ball mill at a speed of 300 rpm hours to mix. Add 13 grams of polyvinyl butyral, 6 grams of dibutyl phthalate, and 6 grams of polyethylene glycol 200 to the slurry mixed by ball milling, and then ball mill with a planetary ball mill at a speed of 300 rpm. Mix well for 16 hours. The above ball-milled slurry was subjected to vacuum degassing treatment for 30 minutes, and cast on a tape casting machine to form a green body of yttria-stabilized zirconia support body. The thickness of the green body support body after drying was 700 μm.

[0030] (2) dissolving ethyl cellulose in terpineol, making ethyl cellulose content is the ethyl cellulose terpineol solution of 2wt% in terpineol, to be applied to the depositing of electrolyte layer as screen printing...

Embodiment 2

[0038] (1) Co-sintering the YSZ support body green body and the electrolyte layer according to Example 1 to prepare the support body and the electrolyte layer.

[0039] (2) preparation concentration is respectively the mixed solution of lanthanum nitrate and chromium nitrate of 1 mole / liter, extracts certain solution with syringe, according to the method for embodiment 1, impregnates above-mentioned solution in the porous YSZ framework, then the matrix after impregnation is good Put it in a furnace at 250°C for half an hour to decompose the nitrates. After repeating the above operation 5 times, put it into a furnace for calcination at 800°C for 2 hours to form lanthanum chromate (LaCrO 3 ), so that the amount of lanthanum chromate reaches 10 mg / cm2. Then use the same method of Example 1 to impregnate to obtain V 2 o 5 , V 2 o 5 The amount is also required to reach 10 mg / cm2.

Embodiment 3

[0041] (1) Prepare the YSZ support body green body and ethylcellulose terpineol solution according to Example 1.

[0042] (2) Add 5 grams of YSZ powder to 6 ml of ethyl cellulose terpineol solution, grind for more than 2 hours to obtain a stable and uniform slurry, and evenly deposit the prepared electrolyte slurry on the YSZ on a screen printing machine The electrolyte layer is formed on the green support body.

[0043] (3) Co-sintering the YSZ support body green body and the electrolyte layer according to Example 1 to prepare the support body and the electrolyte layer.

[0044] (4) Carry out the deposition of the nano electrocatalyst in the framework of the porous YSZ structure according to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com