Lignin modified filter material loading denitration and sulfur-resistant catalyst with double-layer core-shell structure and preparation method of lignin modified filter material

A core-shell structure and catalyst technology, applied in the field of functional composite filter materials, can solve problems such as non-renewable regeneration effect, and achieve the effects of good sulfur resistance, simple reaction synthesis method and operation, and simple use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

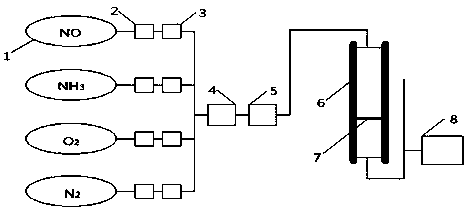

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a lignin-modified filter material loaded with a double-layer core-shell structure denitrification and anti-sulfur catalyst, the specific steps are:

[0029] 1) Preparation of double-layer core-shell structure denitrification and anti-sulfur catalyst: Weigh 0.5g dry polystyrene microspheres, dilute with 50mL distilled water and ultrasonicate for 1h to form a homogeneous system, weigh 0.0136g sodium dodecyl sulfate and add the above system, sonicate for 1h, weigh 0.412g of cerium nitrate into the above solution, and sonicate for 1h. Weigh 0.15g of potassium permanganate and dissolve it in 50ml of deionized water, and slowly add it to the above solution. 80 degrees Celsius water bath for 3h, centrifugal drying to obtain the core-shell structure Mn-Ce-O X catalyst. Weigh 0.2g of ammonium metavanadate hydrate, dissolve in 4mL of 25-28% ammonia water, then add 40mL of distilled water, stir to dissolve. The dried 0.3g core-shell structure Mn-Ce-O X A...

Embodiment 2

[0037] A method for preparing a lignin-modified filter material loaded with a double-layer core-shell structure denitrification and anti-sulfur catalyst, the specific steps are:

[0038] 1) The preparation of the double-layer core-shell structure denitrification and anti-sulfur catalyst is the same as in Example 1.

[0039] 2) Preparation of functional filter material loaded with double-layer core-shell structure denitrification and anti-sulfur catalyst:

[0040] (1) Add 0.1g of lignin to 50mL of deionized water and stir to dissolve to form a lignin solution; add 0.6g of polyphenylene sulfide filter material to the obtained lignin solution, and ultrasonically treat it for 2 hours to make lignin pass through the π- The mechanism of π-conjugation fully covers the surface of the filter fiber;

[0041] (2) Add 0.2 g of the above prepared hollow structure denitrification and anti-sulfur catalyst into a small beaker with ethanol and ultrasonically dissolve it to make a suspension; ...

Embodiment 3

[0046] A method for preparing a lignin-modified filter material loaded with a double-layer core-shell structure denitrification and anti-sulfur catalyst, the specific steps are:

[0047] 1) The preparation of the double-layer core-shell structure denitrification and anti-sulfur catalyst is the same as in Example 1.

[0048] 2) Preparation of functional filter material loaded with double-layer core-shell structure denitrification and anti-sulfur catalyst:

[0049] (1) Add 0.1g of lignin to 50mL of deionized water and stir to dissolve to form a lignin solution; add 0.6g of polyphenylene sulfide filter material to the obtained lignin solution, and ultrasonically treat it for 2 hours to make lignin pass through the π- The mechanism of π-conjugation fully covers the surface of the filter fiber;

[0050] (2) Add 0.2 g of the above prepared hollow structure denitrification and anti-sulfur catalyst into a small beaker with ethanol and ultrasonically dissolve it to make a suspension; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com