Melt flux for submerged-arc welding

A technology of fusion welding and submerged arc welding, which is applied in the direction of arc welding equipment, welding medium, welding equipment, etc., can solve difficult problems such as performance, and achieve the effects of improving welding workability, improving low temperature toughness, and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] Hereinafter, the effects of the examples of the present invention will be described in comparison with comparative examples outside the scope of the present invention.

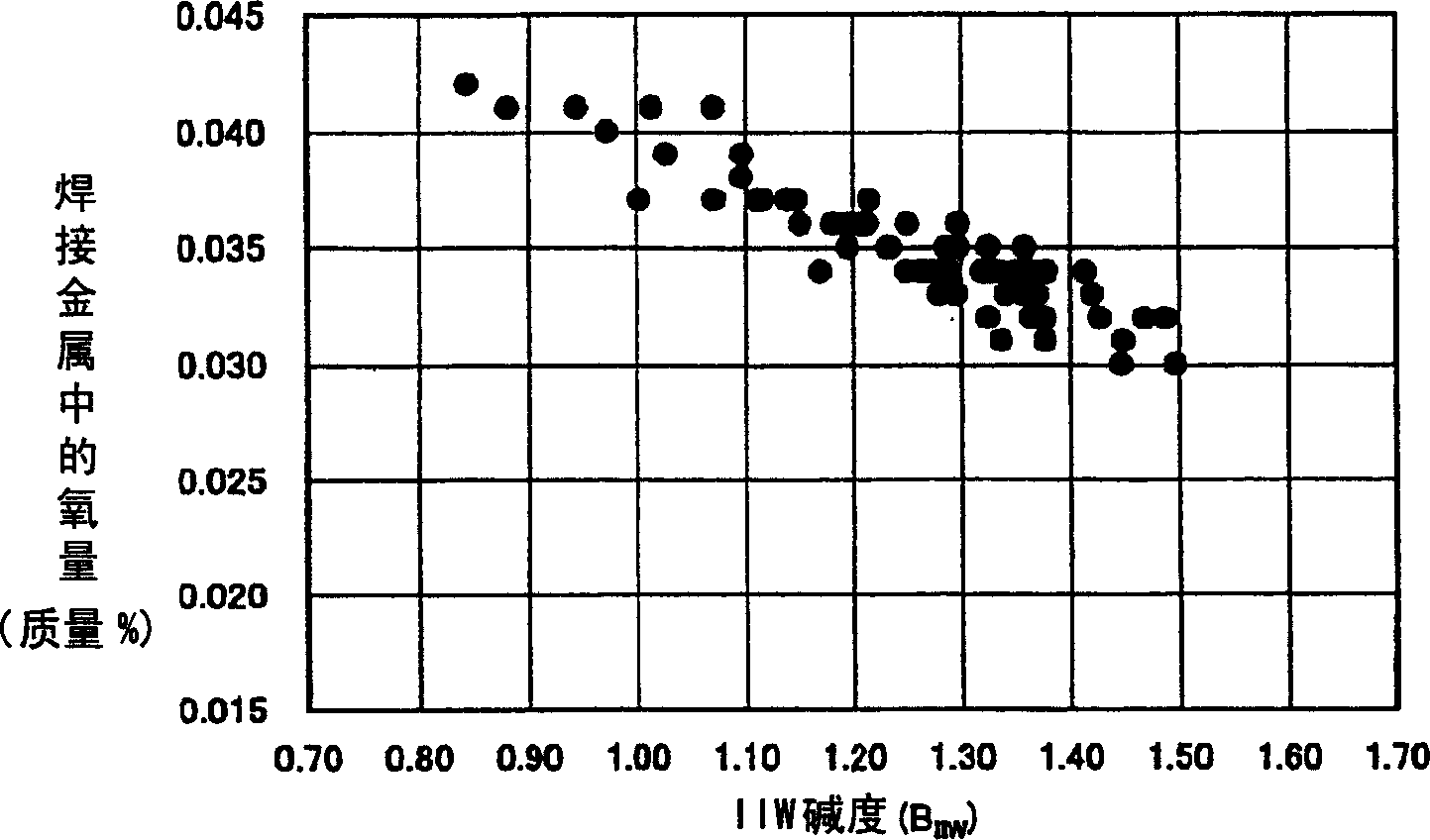

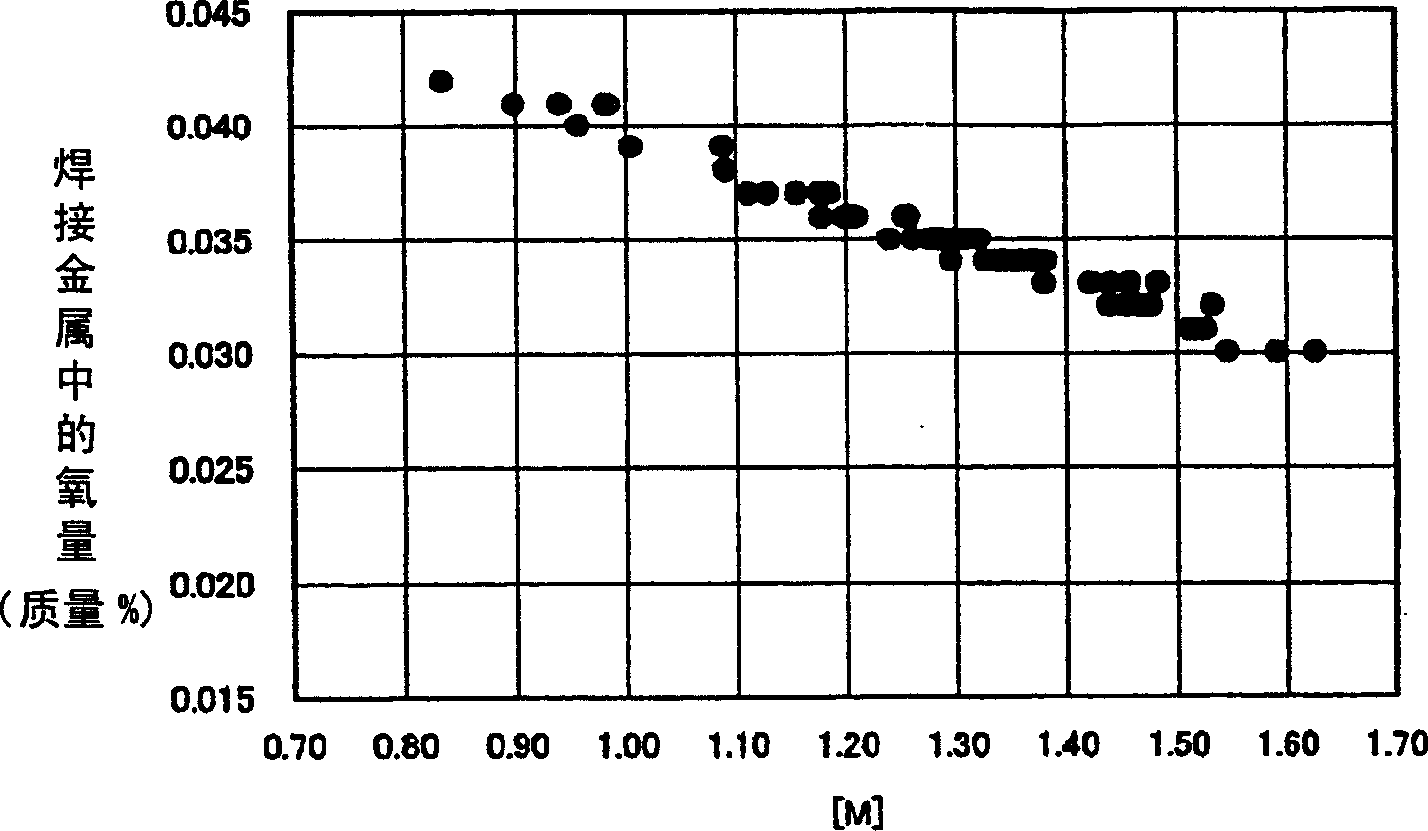

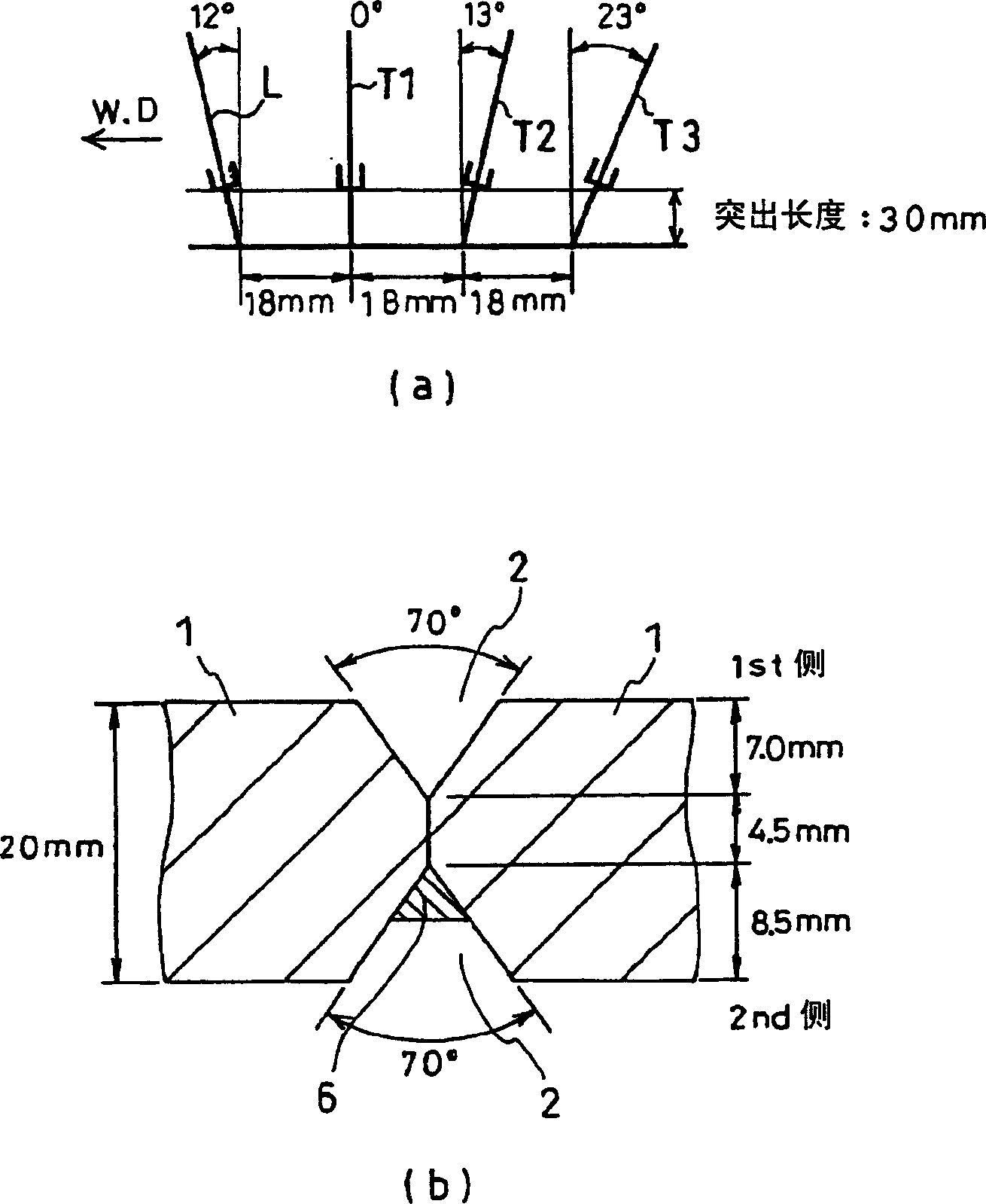

[0066] image 3 (a) is a schematic diagram showing the electrode arrangement of four-electrode welding, and (b) is a cross-sectional view showing the groove shape at this time. in addition, Figure 4 (a) is a schematic diagram showing the electrode arrangement of 3-electrode welding, and (b) is a cross-sectional view showing the groove shape at this time. First, a test steel plate having a composition (JIS standard G3160 SM490A) shown in Table 1 below and a thickness of 20 mm was used with a welding wire (JIS Z3351 YS-S6, diameter 4.0 mm) having a composition shown in Table 2 below and the following: For fluxes with the composition shown in Table 3.1 and Table 3.2, in the above Table 4, image 3 (a), (b) and Figure 4 Under the conditions shown in (a) and (b), the double-sided single-layer welding o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com