System and method for trapping acid gas in smoke

An acid gas and flue gas technology, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high system energy consumption, excessive energy consumption, and absorption load limited by reaction balance, and achieve energy consumption. The effect of reducing and reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

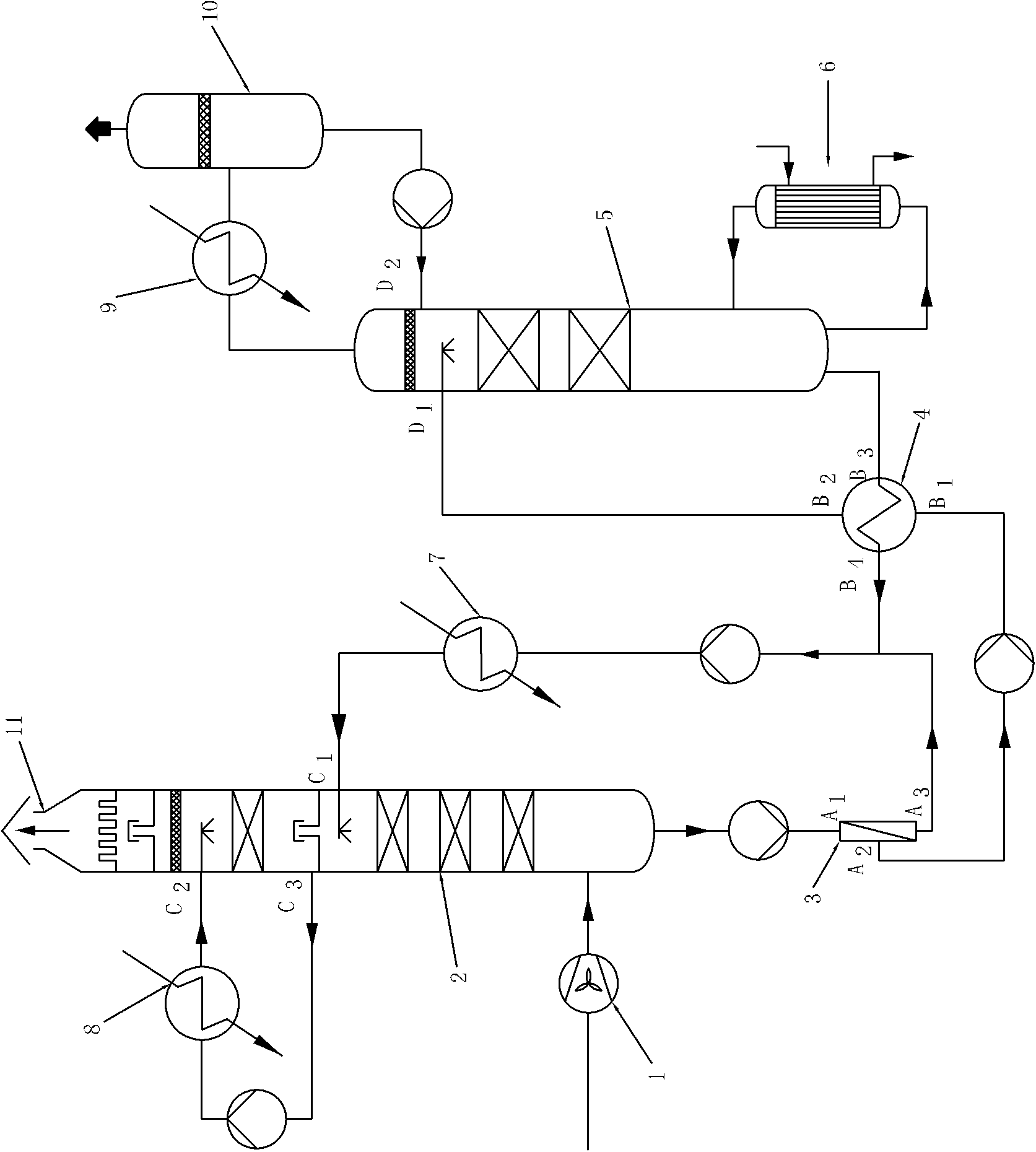

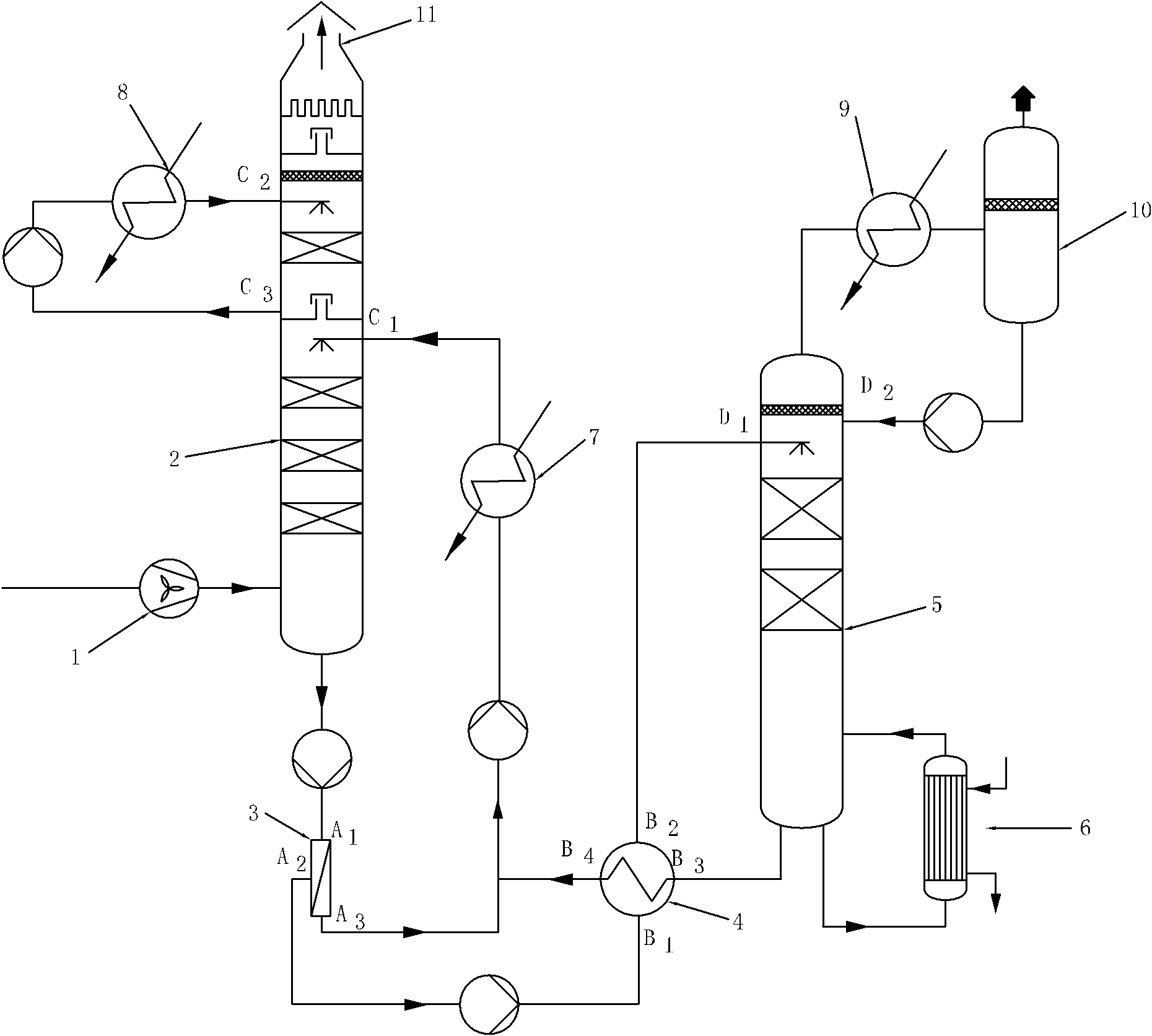

[0017] Combining the composition and connection mode of the system and the CO 2 , SO 2 The embodiment of the specific capture method further illustrates the present invention.

[0018] Such as figure 1 As shown, the booster fan 1 is connected to the air inlet at the bottom of the absorption tower 2, and the bottom of the absorption tower 2 passes through the absorption liquid inlet A of the pump and the liquid film concentration device 3 1 Connected, the concentrated solution outlet A of the liquid membrane concentration device 3 2 Rich liquid inlet B via pump and lean rich liquid heat exchanger 4 1 Connected, the water outlet A of the liquid membrane concentration device 3 3 and the lean liquid outlet B of the lean rich liquid heat exchanger 4 4 Connected, the rich liquid outlet B of the poor rich liquid heat exchanger 4 2 and the first liquid inlet D at the top of regeneration tower 5 1 Connected, the liquid outlet at the bottom of the regeneration tower 5 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com