Elution-method soil remediation process

A soil remediation and leaching technology, applied in the field of contaminated soil remediation, can solve the problems of long remediation time, slow pollutant speed, and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

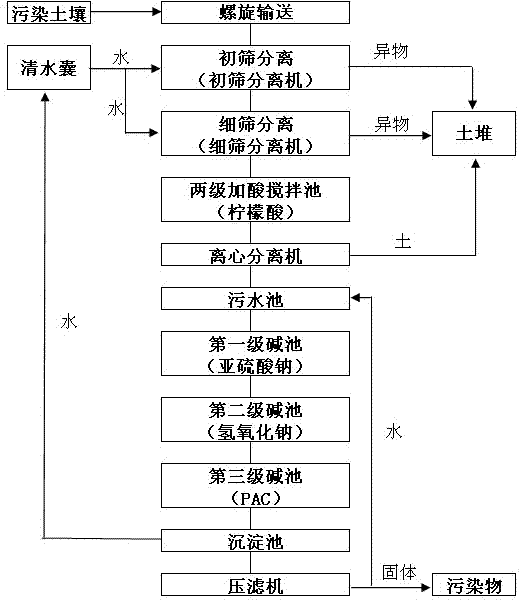

[0027] The specific embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing:

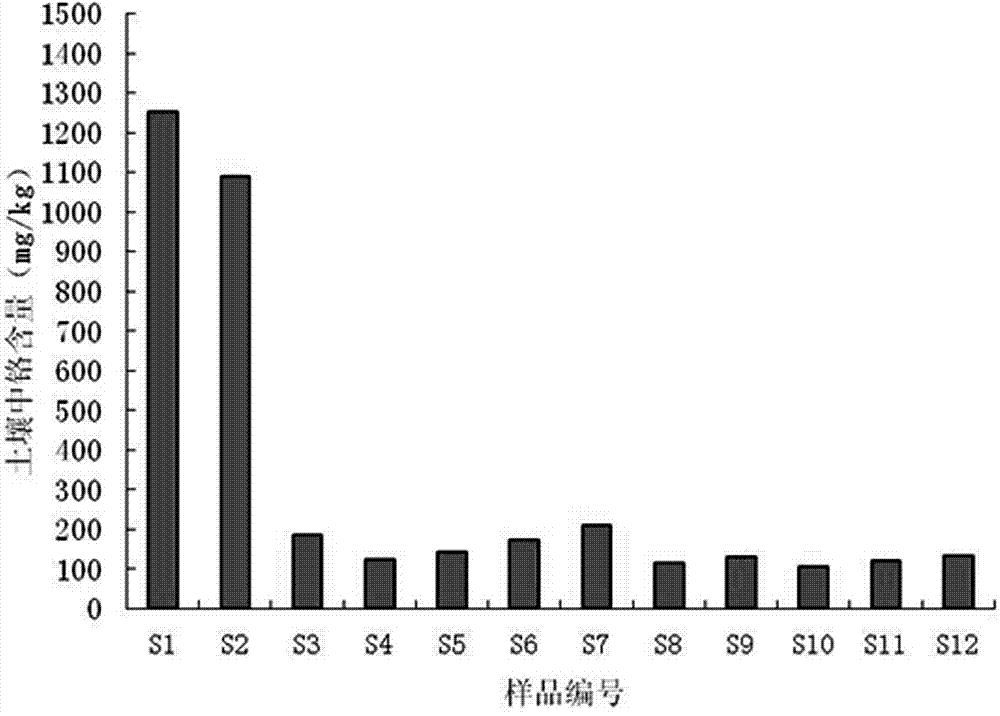

[0028] In a piece of chromium-contaminated soil, one sample was taken from every 10 square meters of soil, and a total of 12 samples were selected and labeled S1-S12 in sequence. S1 and S2 were not treated, and the chromium content was directly tested. S3-S12 was subjected to the following leaching method soil Measurement of chromium balance after repair process:

[0029] (1) Feeding: Send the polluted soil to the inlet of the primary screening separator through the screw conveyor;

[0030] (2) Primary screening and separation: the soil is washed by high-pressure water in the screen cage of the primary screening separator. The mesh of the screen cage is 4 mesh. Water flushing is that the muddy water enters the primary screening liquid storage tank from the mesh of the screen cage, and the circulating stirring pump in the primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com