Comprehensive treatment technology of kitchen garbage

A comprehensive treatment technology for food waste, which is applied in the direction of organic fertilizers and climate change adaptation, can solve the problems of secondary environmental pollution, long processing time, and large floor area, and achieve strong controllability, reasonable process design, The effect of short production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

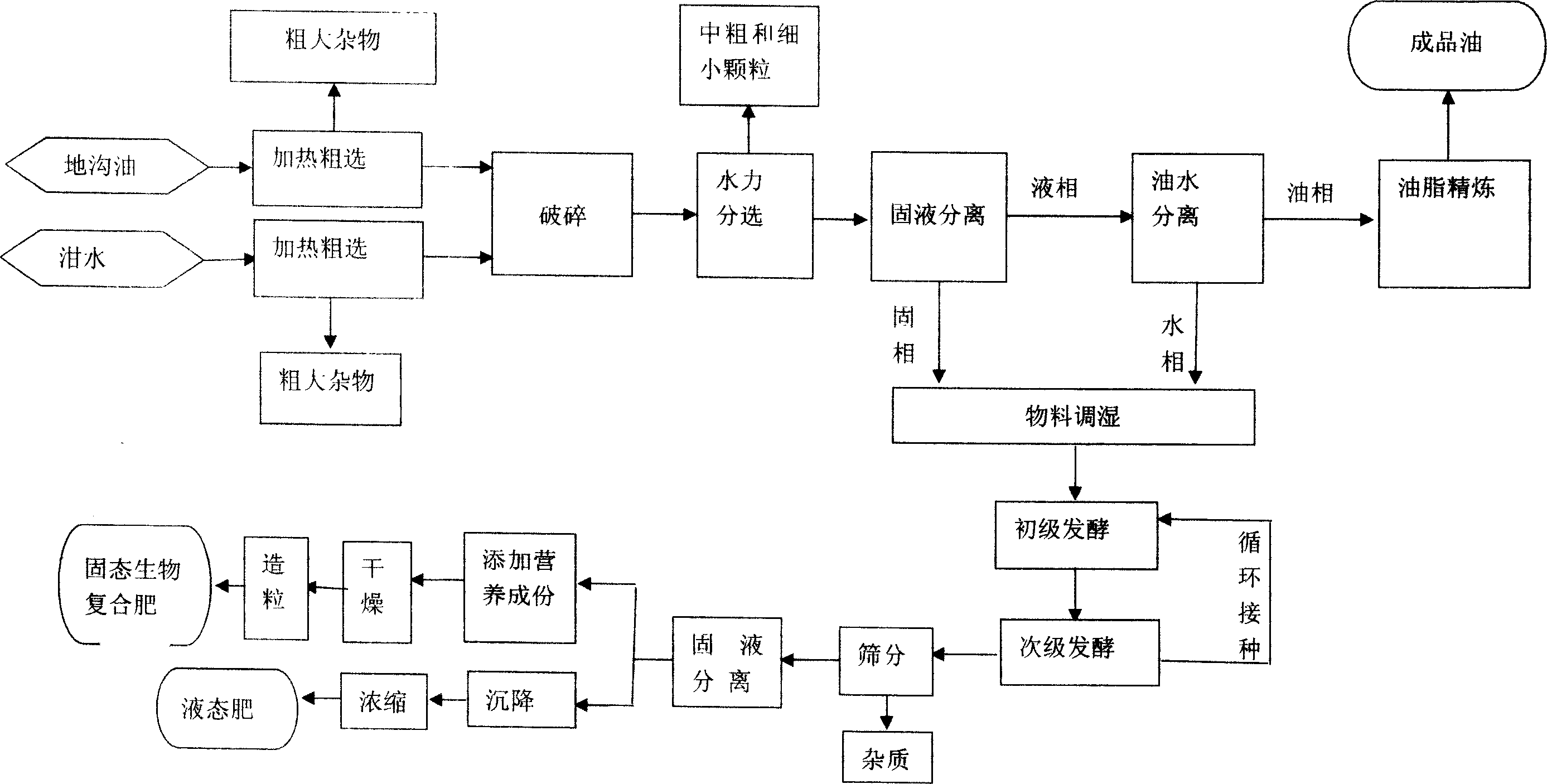

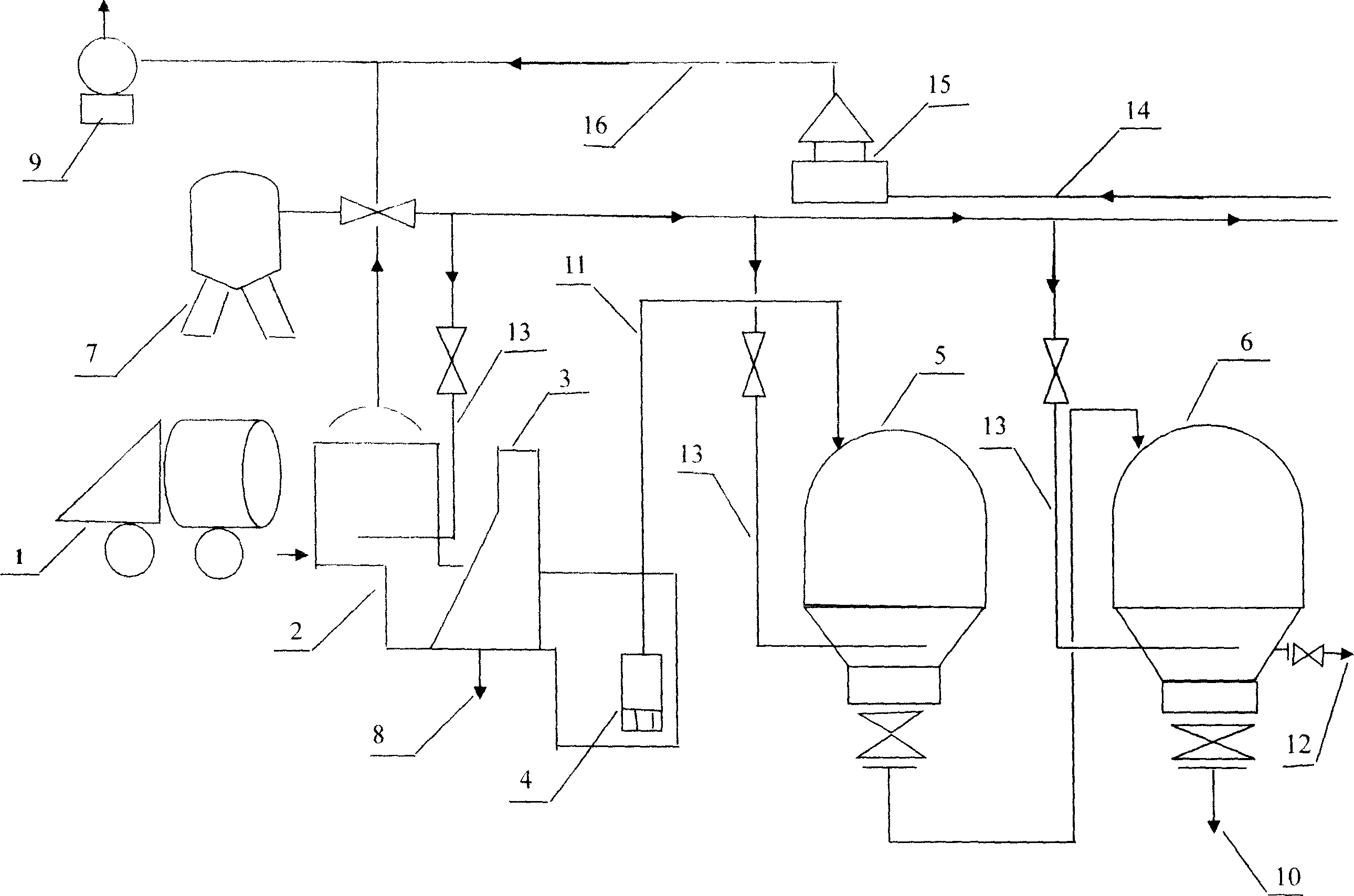

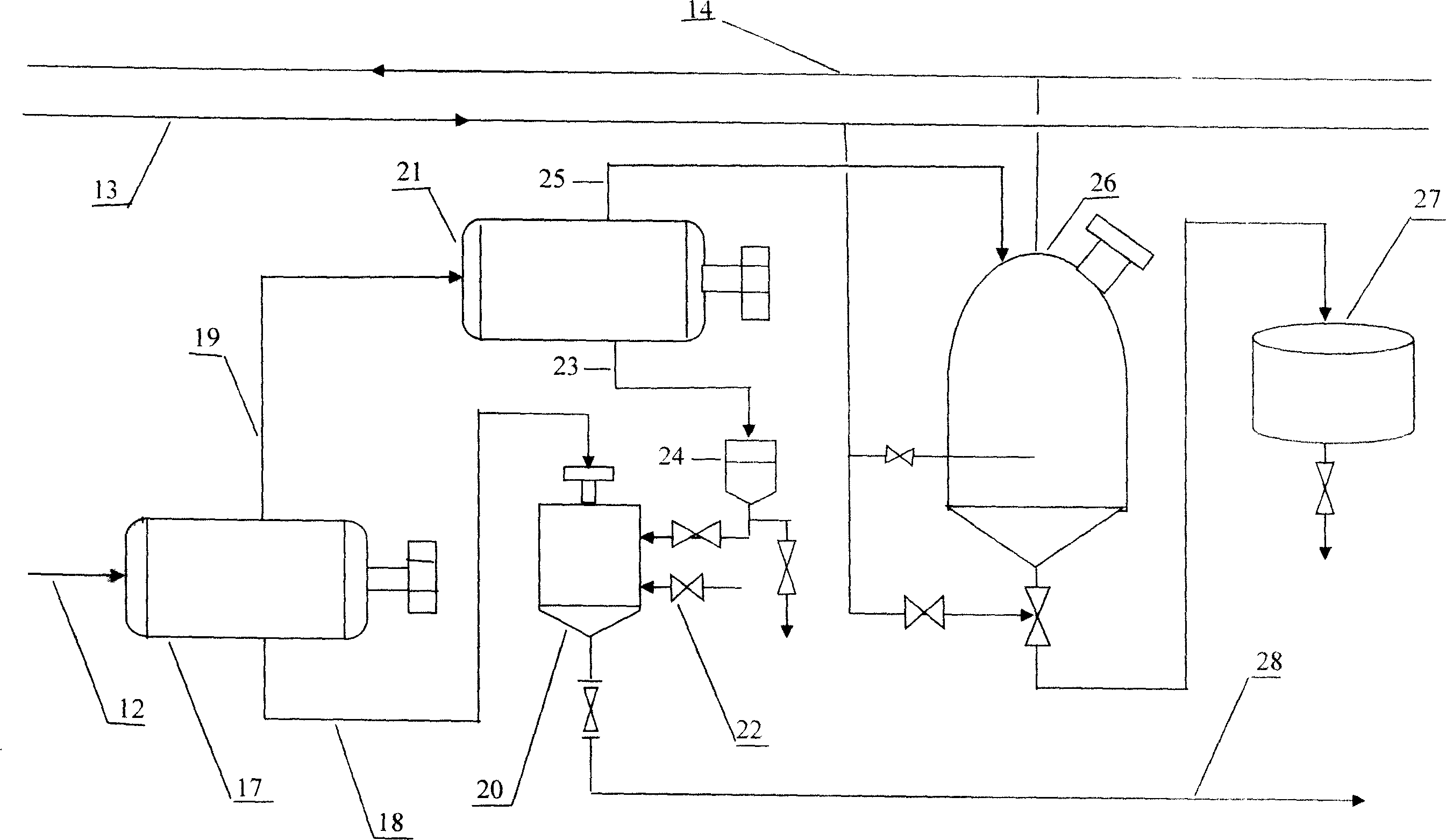

[0014] As shown in Figure 1: its technological process comprises the following steps:

[0015] (1) Coarse sorting: heating the collected kitchen waste such as swill and waste oil to remove large pieces of rough and hard waste;

[0016] (2) Crushing treatment: send the kitchen waste after primary sorting to the crusher, and break it into a slurry;

[0017] (3) Hydraulic separation: the slurry liquid produced in step (2) is sent into a hydraulic separator for sorting, and medium-coarse and fine solid particles are separated to obtain an emulsion liquid containing fine particles;

[0018] (4) Centrifugal separation: the milk slurry obtained in step (3) is first separated through solid-liquid and then oil-water two-stage high-speed centrifuge, so that the milk slurry is separated from solid-liquid and oil-water;

[0019] (5) oil refining: the crude oil obtained in step (4) is refined to produce base oils for the manufacture of biodiesel and other chemical products;

[0020] (6) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com