Cast-in-place process for ultra light foamed cement-based bearing heat insulation wallboard

A foamed cement and thermal insulation wallboard technology, which is applied in the treatment of roofs, walls, and building materials using flat/curved panels, can solve the problems of low construction efficiency, poor overall stiffness performance, and decreased strength, and improve construction. Efficiency, good thermal insulation performance, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

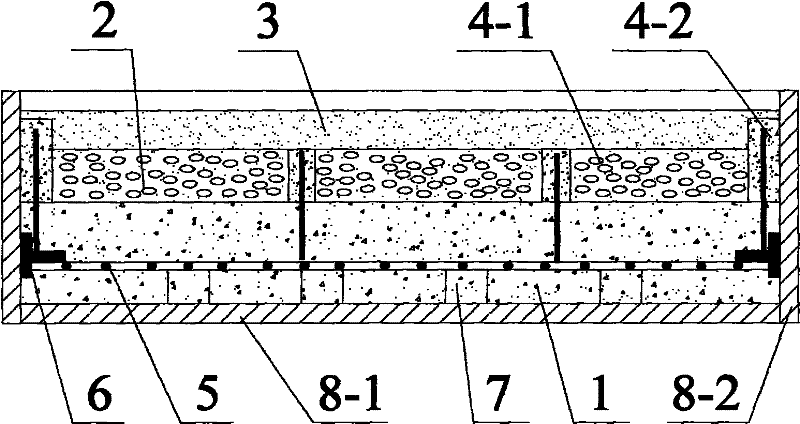

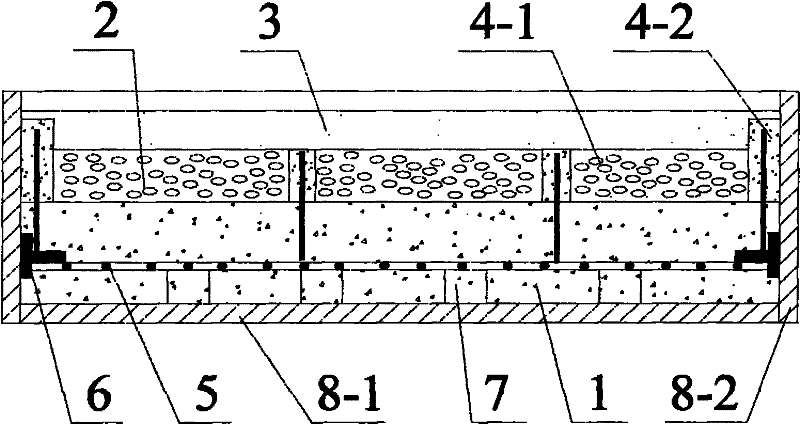

[0017] The cast-in-place process of ultra-light foamed cement-based load-bearing insulation wall panels includes the basic process of preparing the reinforced concrete load-bearing layer 1. The cast-in-place process includes the following processes:

[0018] a. Lay the bottom formwork 8-1 and the side formwork 8-2 to form a groove-shaped concrete forming mold;

[0019] b. Lay the concrete protective layer cushion block 7 on the bottom formwork 8-1, and then pour fine stone concrete into the concrete forming mold to form the reinforced concrete bearing layer 1;

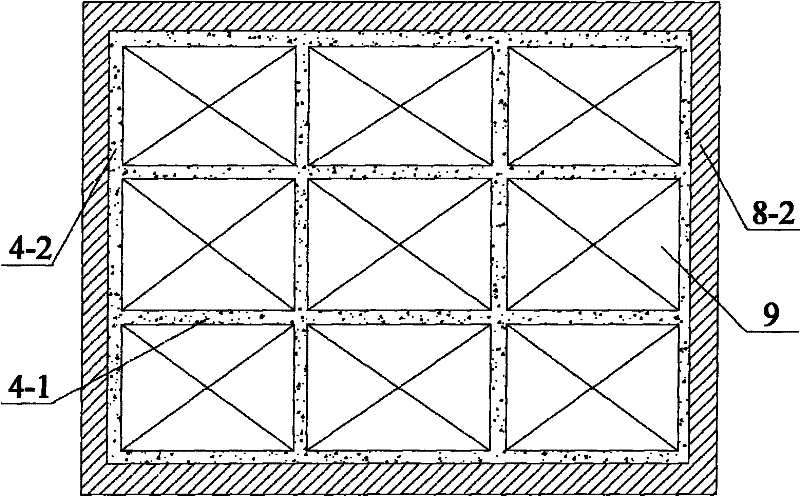

[0020] c. Position the 9 groups of inner mold cores formed by the plate frame on the uninitiated reinforced concrete bearing layer 1 according to the design position of the reinforcing rib;

[0021] d. Pour fine stone concrete into the gap between the 9 sets of inner mold cores, the inner mold core 9 and the forming mold, form the frame 4-2 and the reinforcing rib 4-1 after the initial setting, and place the inner mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com