Solid wall paper and its production method and use

A wallpaper, three-dimensional technology, applied in the direction of paper, papermaking, special paper, etc., can solve the problem that the height of the three-dimensional pattern will not exceed 5mm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] a three-dimensional wallpaper,

[0110] It is characterized by:

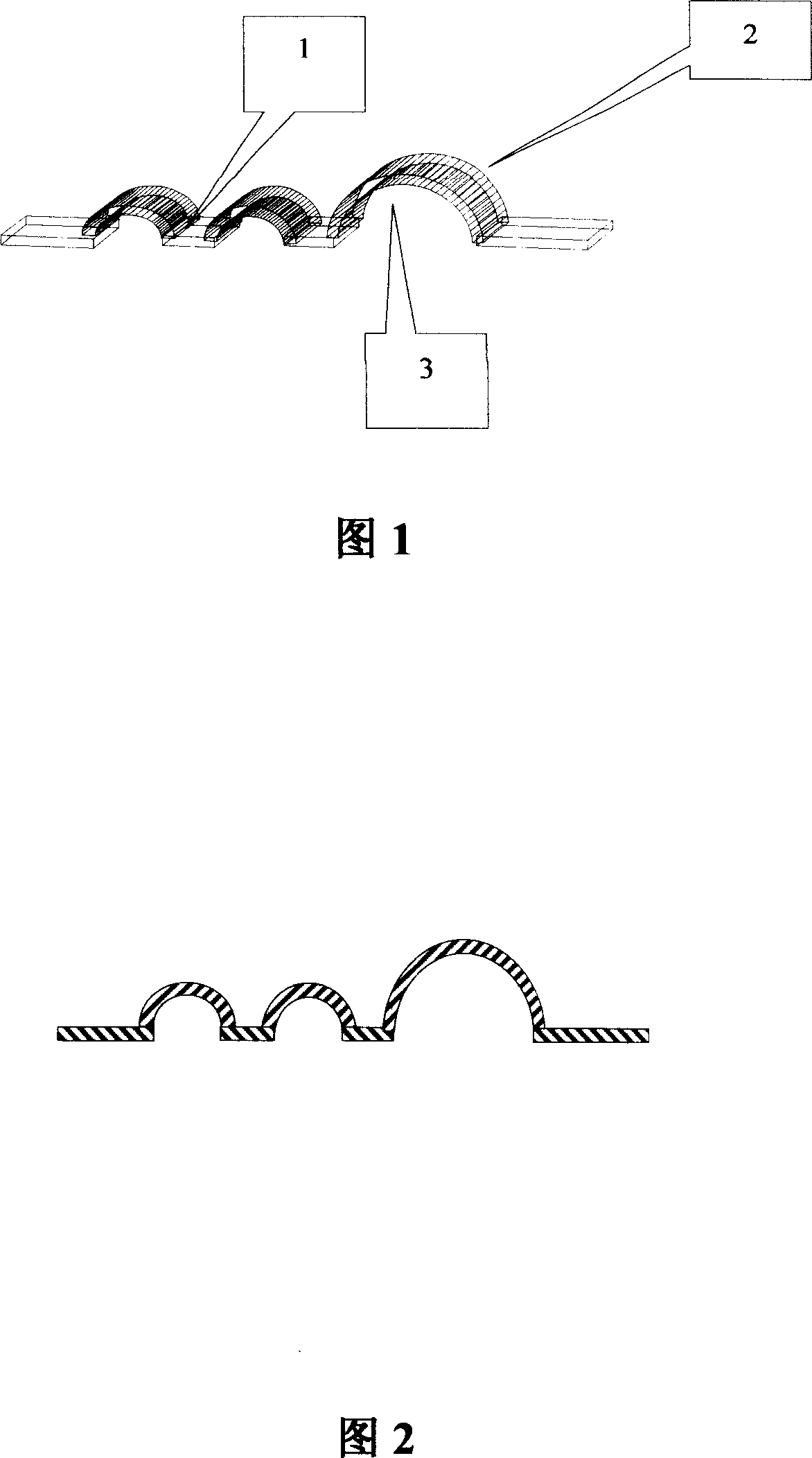

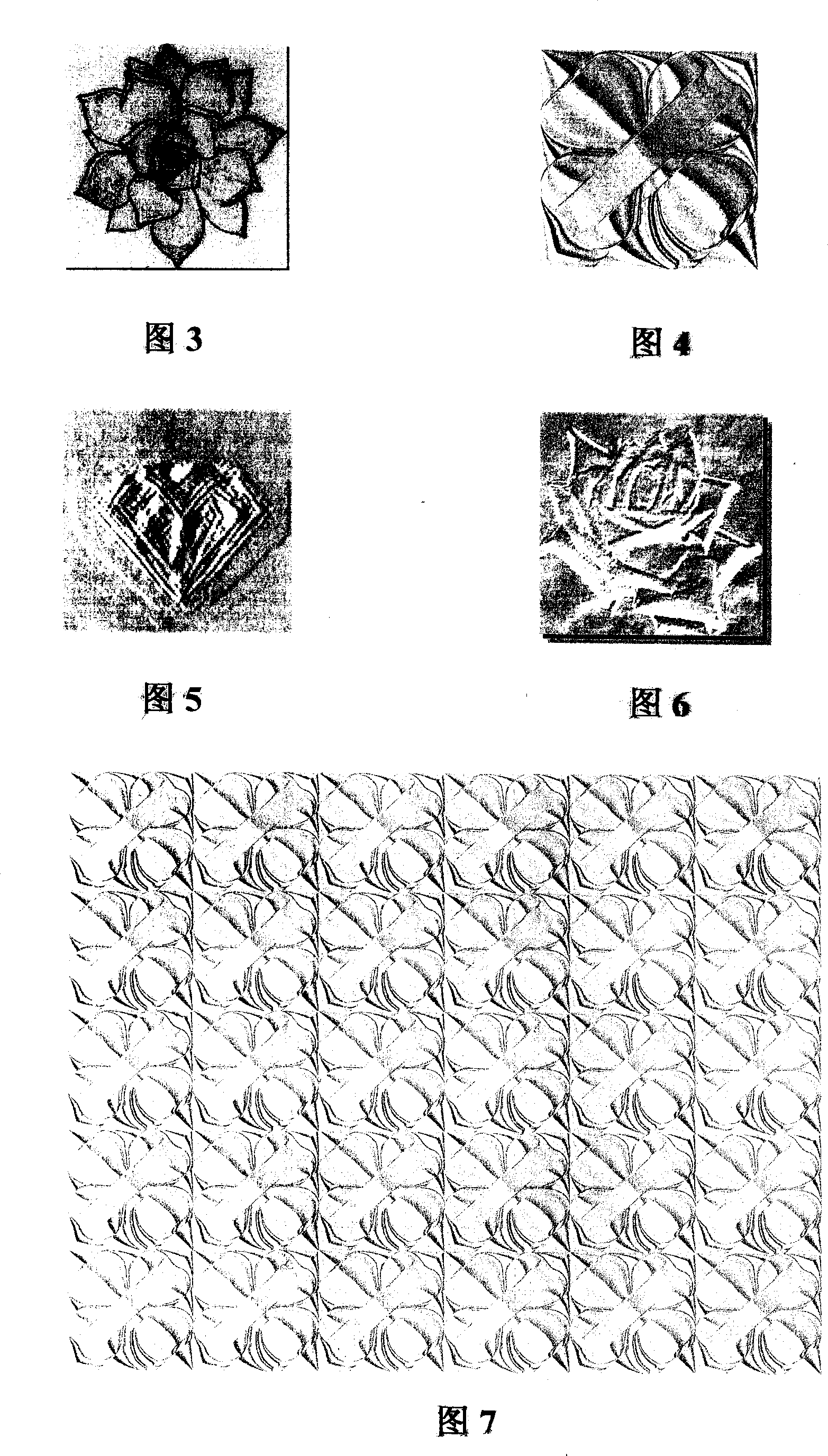

[0111] 1. It is composed of the plane part 1 of the three-dimensional wallpaper; the convex part 2 of the three-dimensional wallpaper; the concave part 3 of the three-dimensional wallpaper; or the three-dimensional wallpaper is made of three-dimensional shape and has convex and concave shape wallpaper;

[0112] and has the following characteristics:

[0113] 2. It has a plate structure. The three-dimensional wallpaper is a single or a single piece. A multi-color three-dimensional wallpaper is formed by splicing, combining and arranging multiple monomers of the same specification and color;

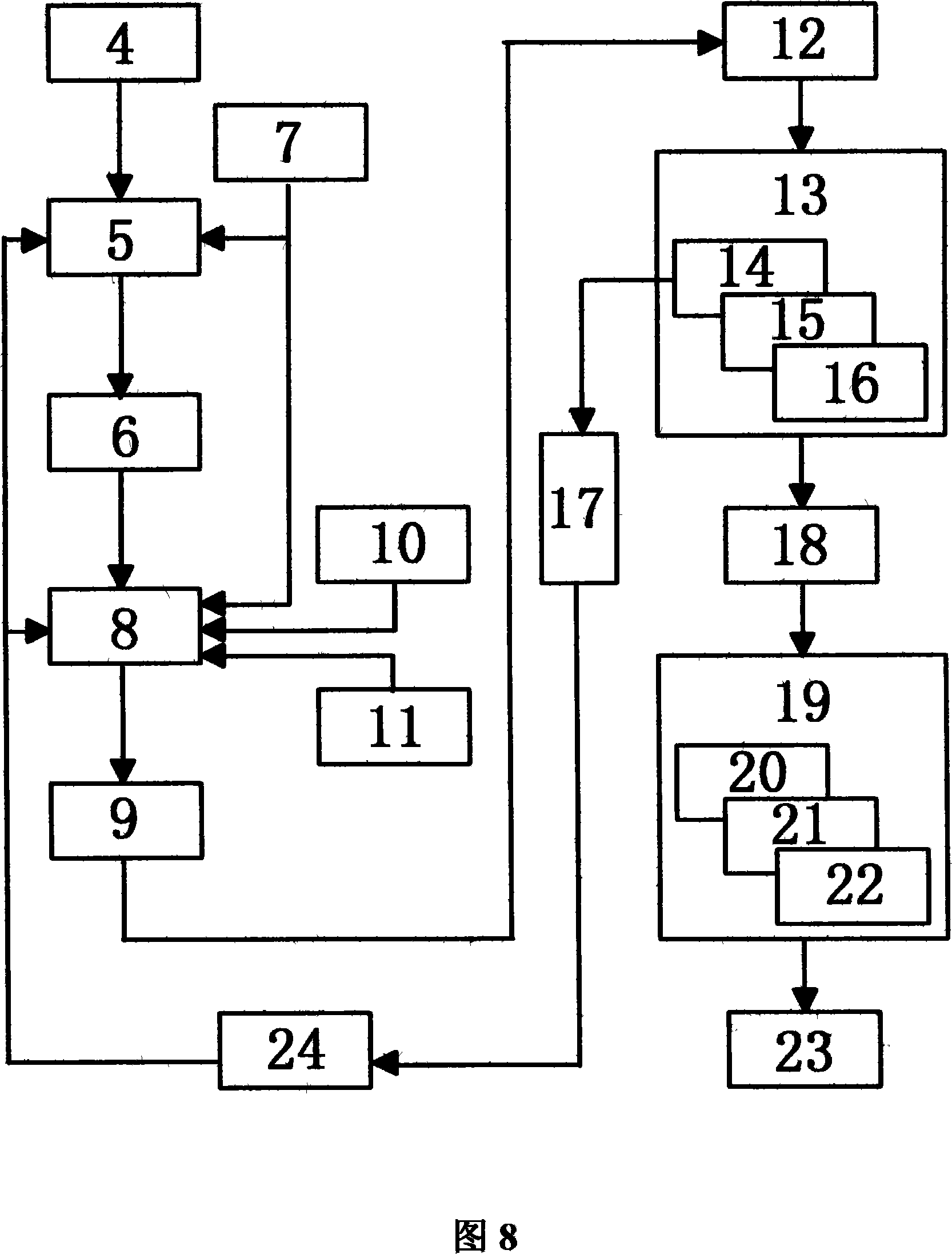

[0114] 3. The three-dimensional wallpaper is made of paper pulp raw materials: either paper pulp raw materials composed of solid fillers and additives added to pure paper pulp or mixed paper pulp raw materials; The paper pulp raw material is composed of coniferous wood pulp, adding one or more of the natural fiber ...

Embodiment 2

[0121] a three-dimensional wallpaper,

[0122] It is characterized in that: In addition to "the three-dimensional wallpaper is composed of papermaking pulp raw materials composed of solid filler 10 and auxiliary agent 11 in papermaking pure wood pulp, and then water with a pH value of 7 or tap water or deionized water 7 is added. The solid filler 10 is: one or more solid fillers in calcium carbonate, talcum powder, titanium dioxide, and fiber reinforced materials, and the auxiliary agent 11 is: one or more of fireproofing agents, waterproofing agents, and adhesives more than one auxiliary agent." Outside, other features are the same as the three-dimensional wallpaper described in embodiment 1.

Embodiment 3

[0124] a three-dimensional wallpaper,

[0125] It is characterized in that: in addition to "the ratio of the thickness of the paper base of the wallpaper to the three-dimensional protruding part is 1:300, the thickness of the three-dimensional wallpaper is between 0.3mm-5mm, the specific gravity is between 03-1.5, and the thickness of the wallpaper paper base is 1.5mm Between -5 millimeters." Outside, other features are identical with the three-dimensional wallpaper described in embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com