Sliding type ceramic tile surface flatness detection device and method thereof

A surface smoothness and detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of untimely detection, high labor intensity, high detection errors, etc., and achieve stable and reliable work, convenient installation and maintenance, and high precision Detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

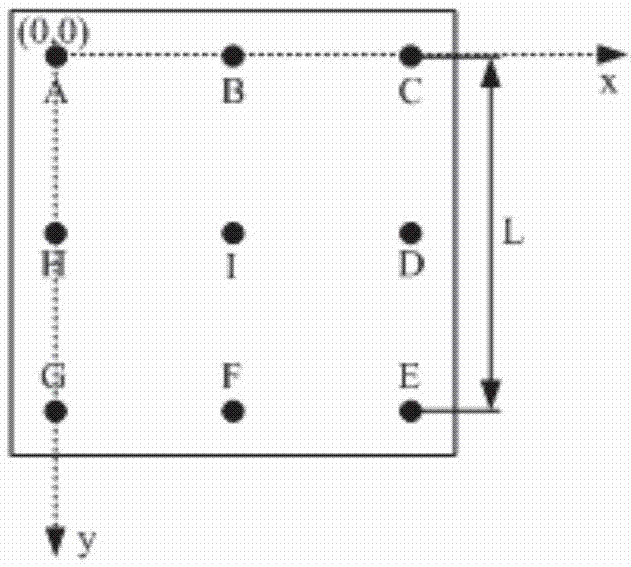

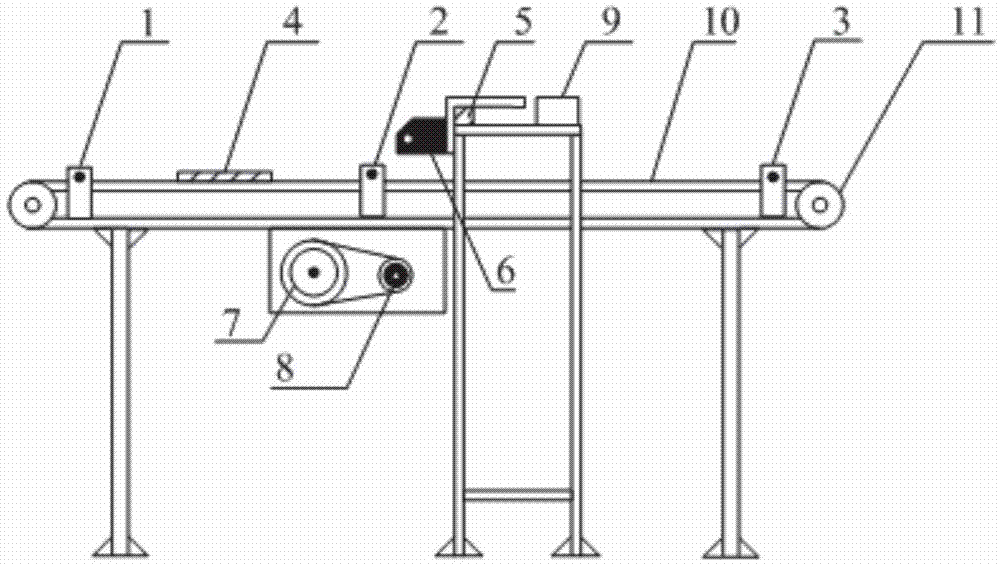

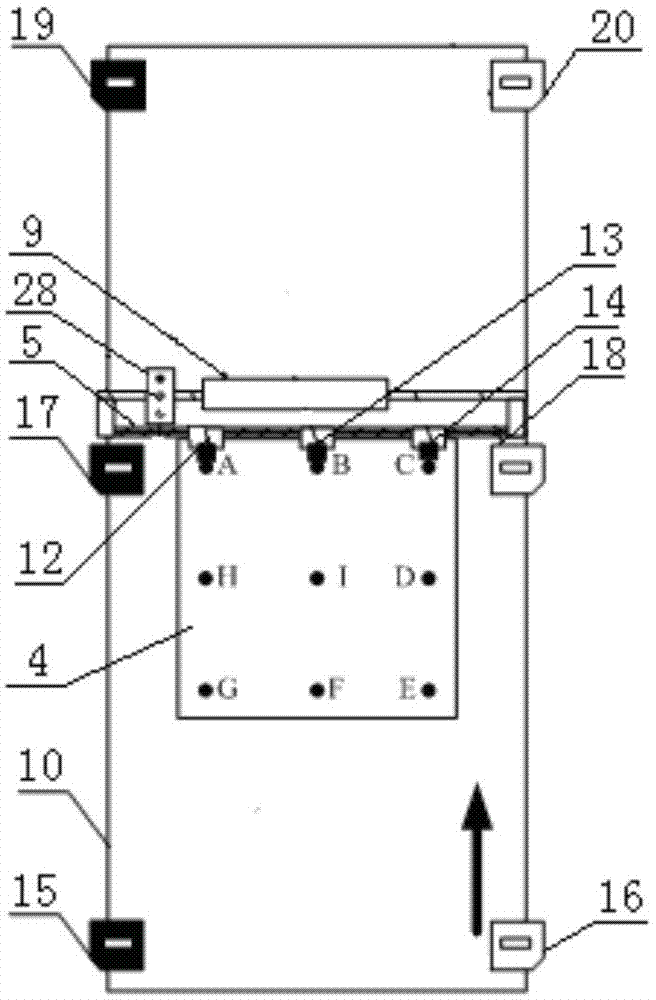

[0028] Such as figure 2 , Figure 4 As shown, a sliding type tile surface smoothness detection device of the present invention includes a laser emitting module, an inductive photoelectric trigger module, a tile transmission module and a data processing module, wherein the tile transmission module is used to transmit the measured ceramic tile 4, and the laser The emitting module is arranged above the ceramic tile transmission module and is connected with the data processing module. The laser emitting module generates a laser beam and obtains the distance information between the surface of the ceramic tile 4 to be tested and the laser emitting module. The data processing module uses In order to process and display the collected surface feature point data of the tested ceramic tile 4 and perform sound and light prompts, the induction photoelectric trigger module is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com