A prefabricated exterior wall structure

A prefabricated assembly and prefabricated technology, applied to walls, building components, building structures, etc., can solve problems such as inconvenient installation, rising costs, and difficulty in ensuring the integrity of the tenon and tenon surfaces, achieving labor saving and structural Simple, good promotion value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings and embodiments.

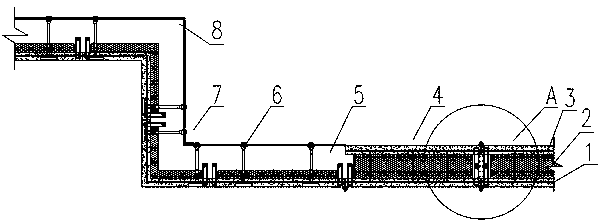

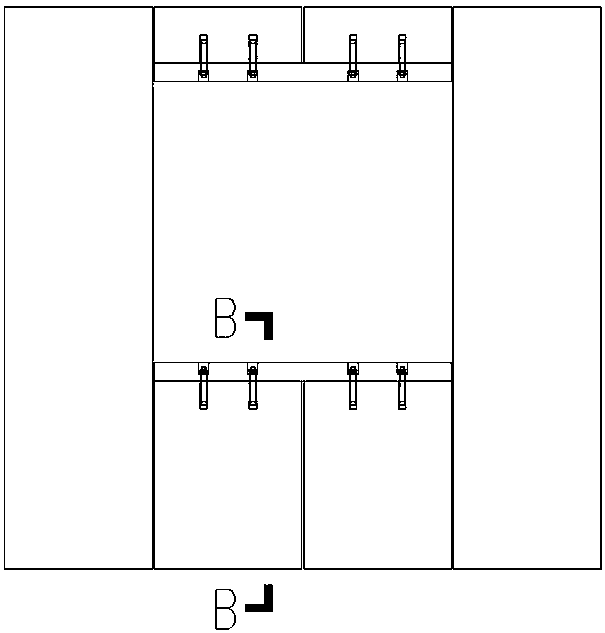

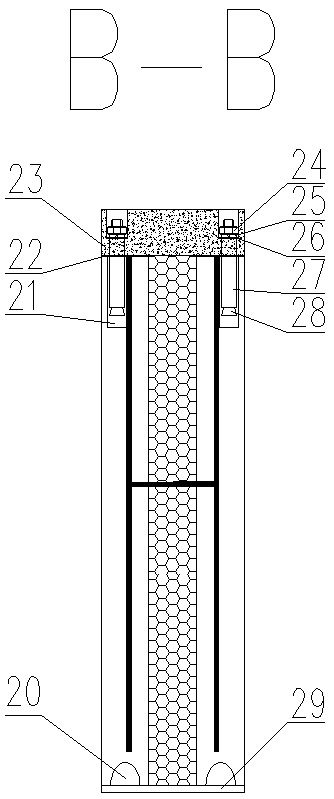

[0042] like figure 1 and figure 2 As shown, an external wall prefabricated structure is composed of thermal insulation composite wall standard parts and auxiliary structures. The thermal insulation composite wall standard parts include prefabricated external wall load-bearing wall standard parts 5, prefabricated external wall non-load-bearing Wall standard parts 4, prefabricated external wall load-bearing wall standard parts 7, prefabricated external wall load-bearing wall internal corner standard parts 8, prefabricated external wall load-bearing wall standard parts 5 Set assembled tie rods for positioning and installation load-bearing Wall Construction Formwork 16.

[0043] Described prefabricated external wall load-bearing wall standard parts 5, prefabricated external wall non-load-bearing wall standard parts 4, prefabricated external wall load-beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com