Pile grinding device for concrete pipe piles

A concrete pipe pile and mill technology, which is applied in the directions of grinding drive device, grinding machine, grinding feed motion, etc., can solve the problems affecting the progress and quality of the project, uneven contact of the end face of the pipe wall, and the flatness of the end face of the pipe wall is not easy to achieve. Standard requirements and other issues, to achieve the effect of easy flatness and uniform contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings, and those skilled in the art can clearly understand the present invention and implement the present invention according to the detailed description. Without departing from the principles of the present invention, the features in different embodiments can be combined to obtain new implementations, or some features in certain embodiments can be replaced to obtain other preferred implementations.

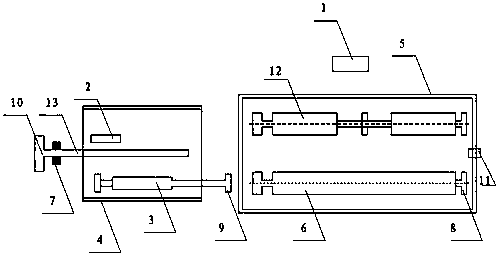

[0030] refer to figure 1 , figure 1 A pile grinding device for concrete pipe piles according to a preferred embodiment of the present invention is shown, which includes: a first speed-regulating motor 1, a second motor 2, a mill 3, a dovetail groove 4, a chassis 5, from Moving supporting roller 6, leading screw tile seat 7, supporting roller bearing tile seat 8, grinding disc 9, leading screw handwheel 10, positioning bearing 11, driving supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com