Method for testing flatness of stator core

A stator core and testing method technology, applied to measuring devices, instruments, optical devices, etc., can solve the problems of inability to guarantee the dynamic balance requirements of parts, large initial unbalance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

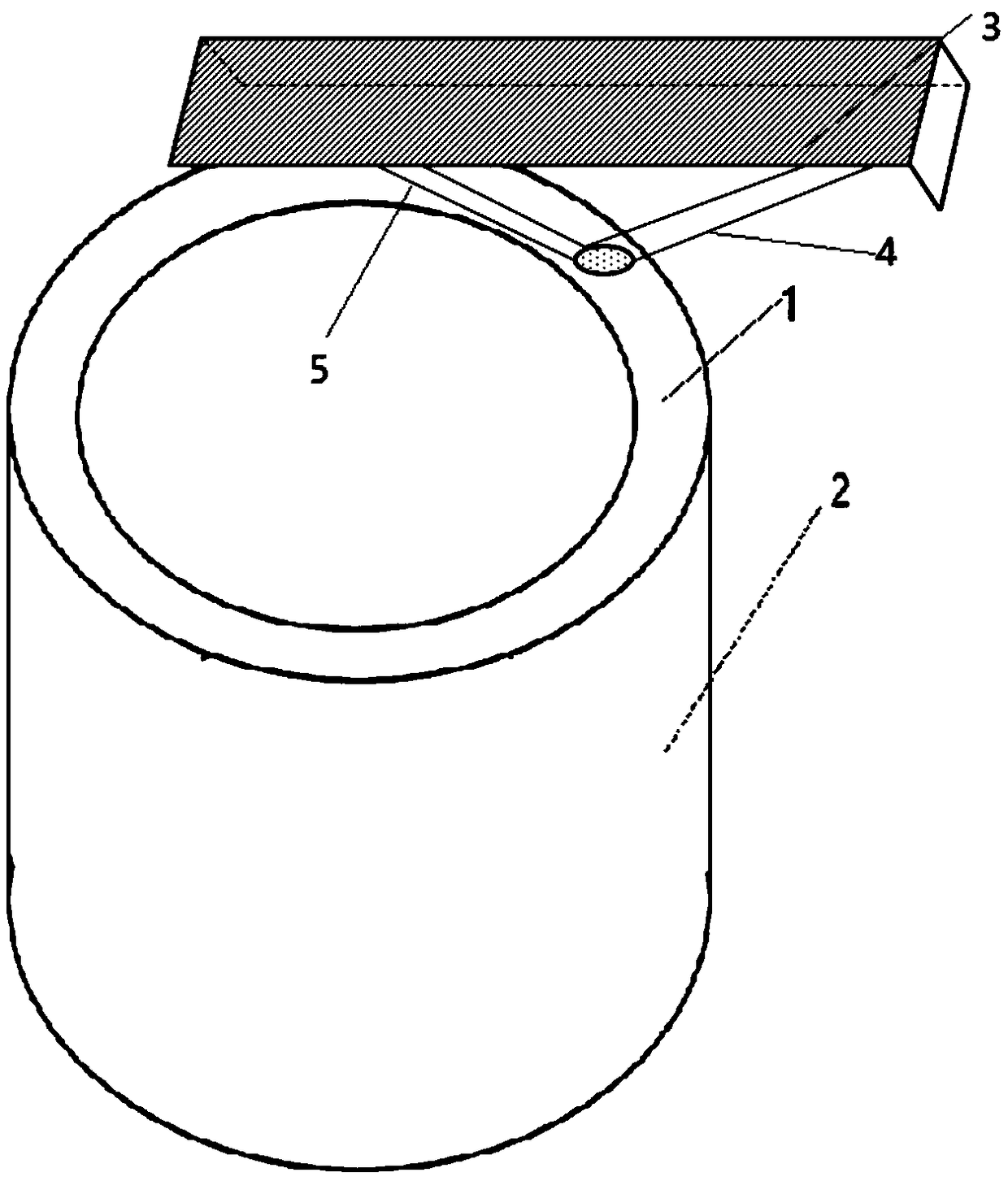

[0015] A method for testing the flatness of a stator core, including a stator core that has been die-cast at high temperature and high pressure, a laser oscillator, a mobile work platform that moves according to a certain working cycle, a timer, and a sensor that detects the mobile work platform. The timer receives The sensor transmits the signal of the movement of the working platform to start timing. The laser oscillator is installed on the mobile working platform 3. The working platform also includes a light receiving and processing device. The laser oscillator scans the end face of the stator core and the outer circumference. The iron core, the light receiving and processing device receives and processes the reflected light, analyzes the deviation value, and records the position of the deviation value, that is, the uneven position. The working platform makes a spiral movement along the upper end of the stator core end face, and The incident angle of the oscillator on the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com