Automatic production technology of aluminum composite panel

An aluminum composite panel, automatic production technology, applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of no automation and continuous production, and achieve low production costs, firm bonding, and reduced effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

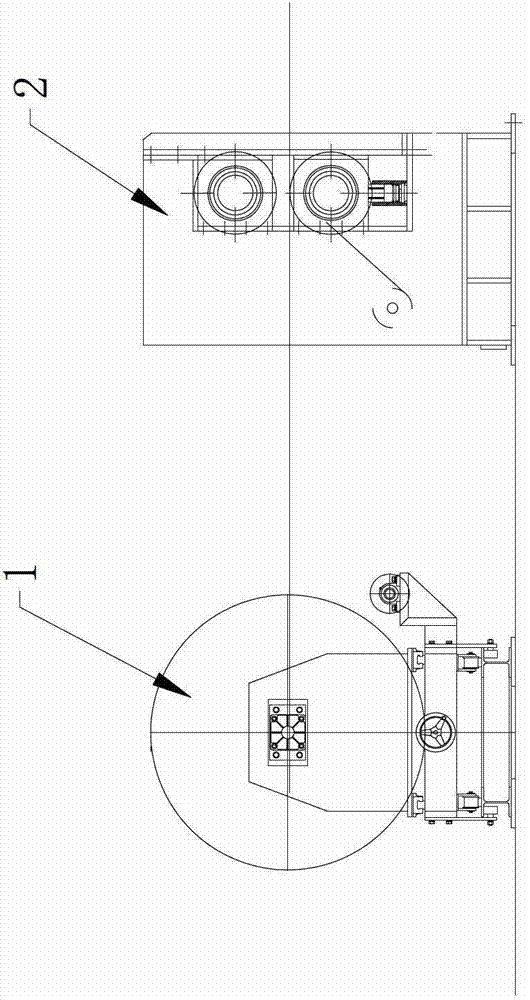

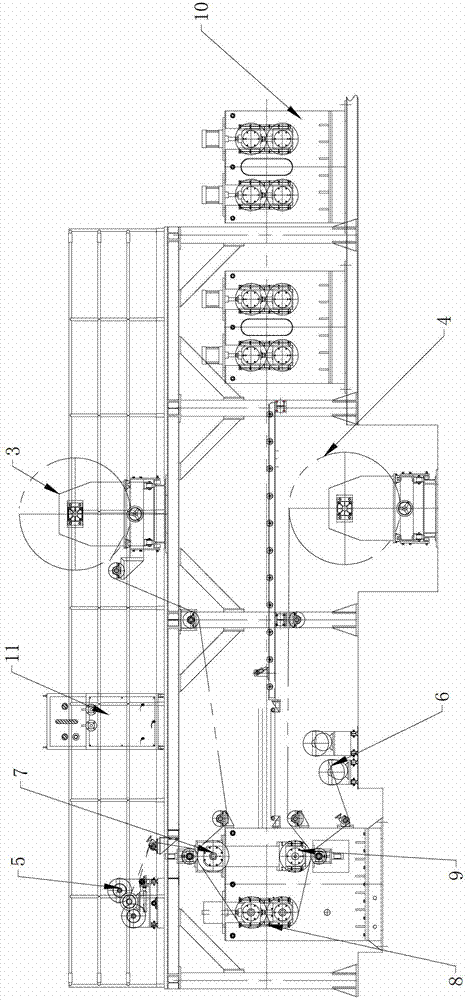

[0030] Such as Figure 1 to Figure 5 As shown, an automatic production process of aluminum composite panels, including:

[0031] (1) Pass the core board 20, surface board 18 and bottom board 24 made of aluminum through the core board 20 unwinding device 1, the surface board 18 unwinding device 3, and the bottom board 24 unwinding device 4. , the upper hot-melt adhesive film 19 and the lower hot-melt adhesive film 23 are unwound by the first film-releasing device 5 and the second film-releasing device 6 respectively; the thickness of the core board 20 is 0.3mm, and the thickness of the surface board 18 0.5mm, the thickness of the bottom plate 24 is 0.5mm, and the thickness of the hot melt adhesive film is 0.1mm. The core board 20, the surface board 18 and the bottom board 24 are all rolled on the corresponding unwinding equipment, and the unwinding equipment is an unwinding machine, and the unwinding machine is the most upstream of the corresponding plate operation. Both the ...

Embodiment 2

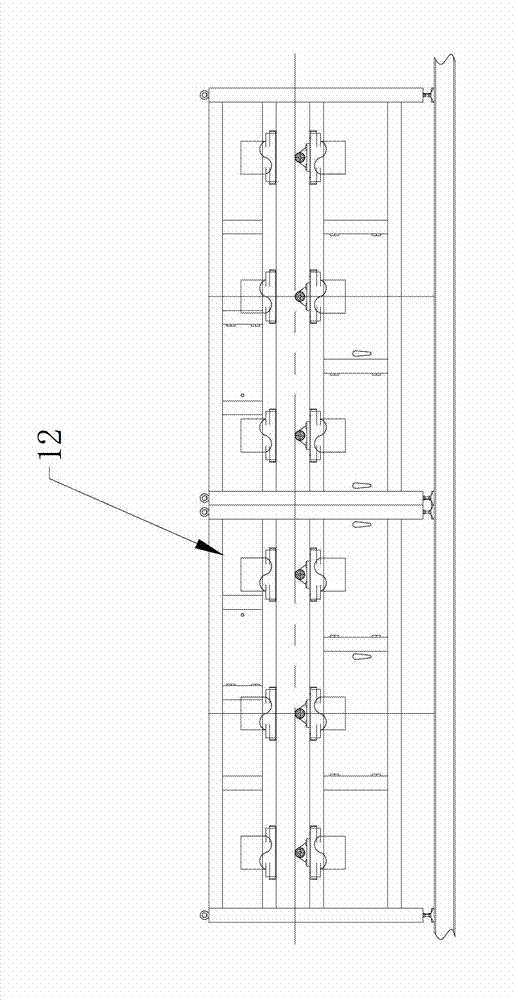

[0039] Such as Figure 6As shown, the production process adopted in this embodiment is the same as that of Example 1, except that the molding machine 2 is slightly adjusted. In the aluminum composite panel produced by this production process, the two board surfaces of the core plate 20 are all pressed with protrusions. Correspondingly, several convex die heads and die cavities are provided on the roll surfaces of the two profiling rollers of the forming machine 2 . Then the convex die head of the upper pressing roller and the concave die cavity of the lower pressing roller cooperate to press the core layer 20 to make it produce a downwardly protruding protrusion, which is called the second protrusion 22; the lower pressing roller The convex die head and the concave die cavity of the upper pressing roller cooperate to make the core plate 20 produce upwardly protruding protrusions, which are called second protrusions 22; the first protrusions 21 are evenly distributed on the pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com