Zoning ink box for printer

A printing machine and ink fountain technology, which is applied in the field of printing machine ink fountains, can solve the problems of thin elastic ink fountain blades, uneven ink supply, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

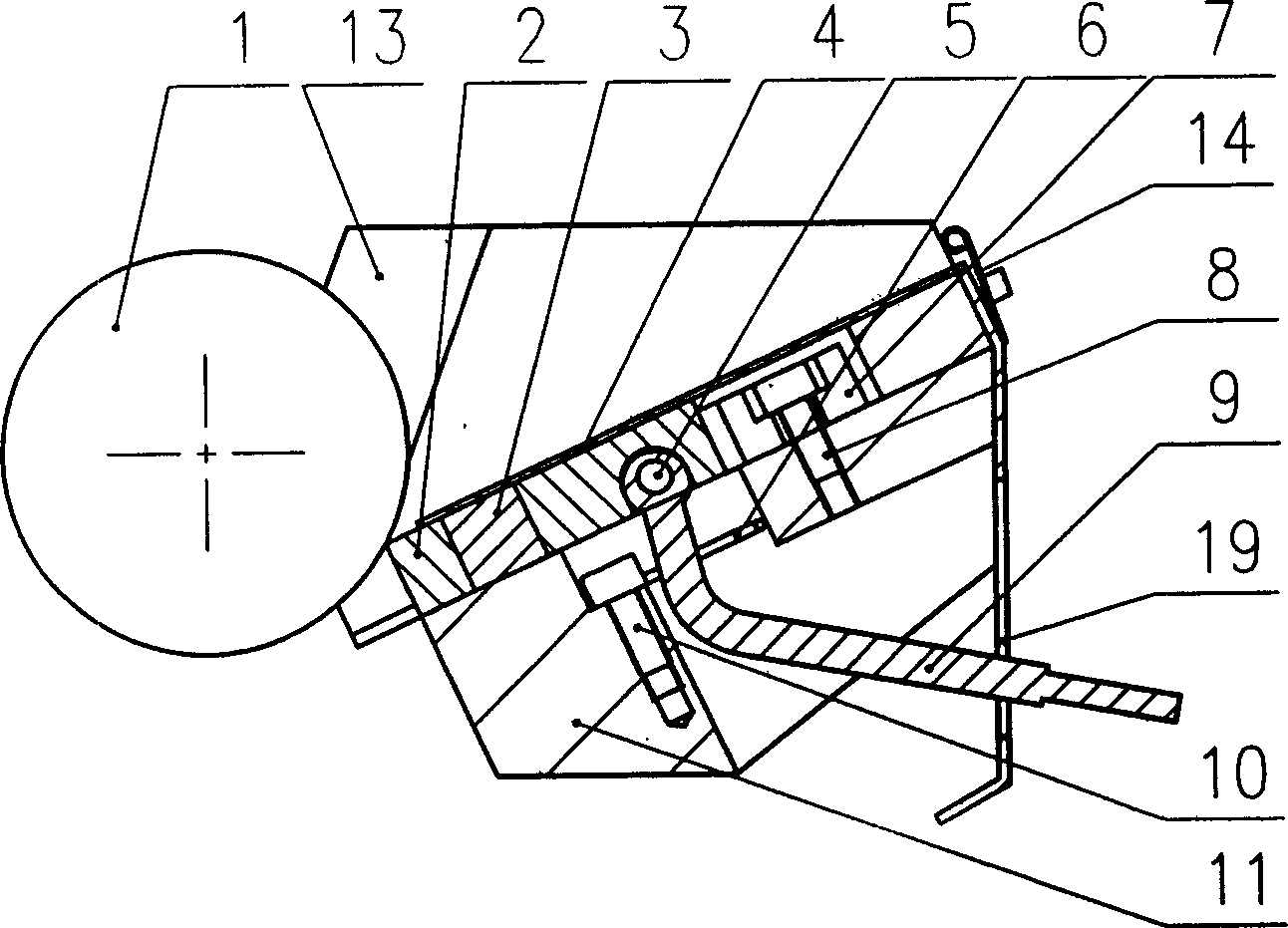

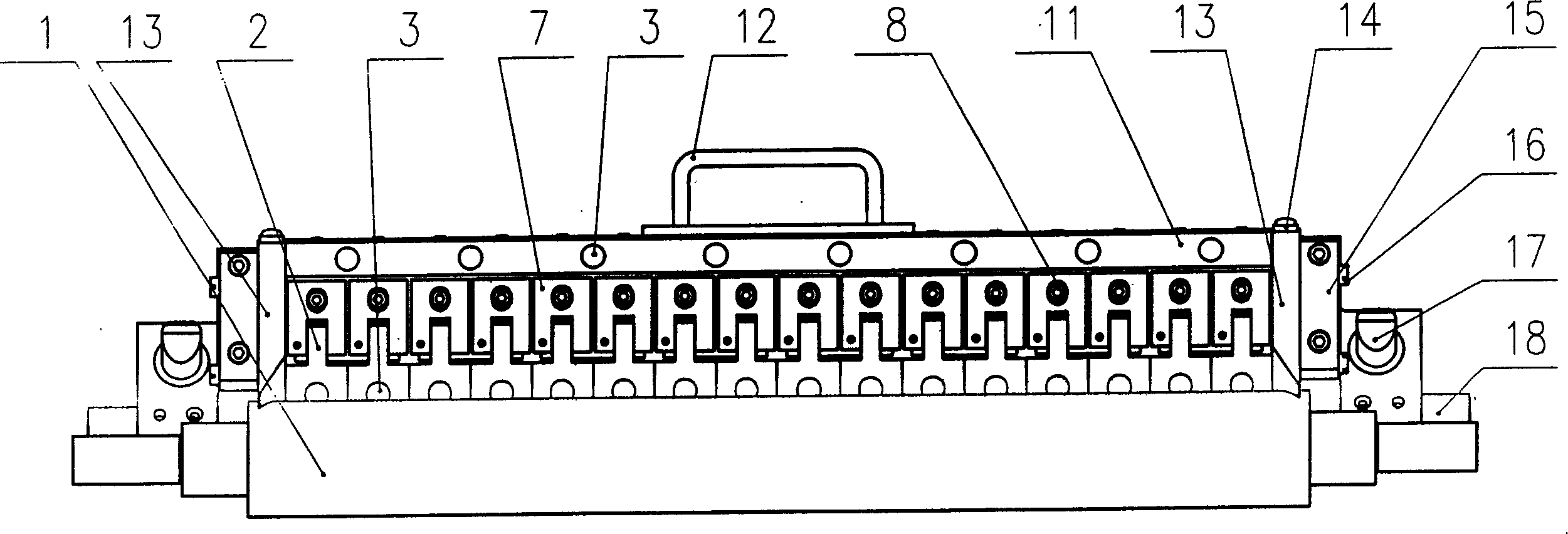

[0012] The partitioned ink fountain of the printing machine shown in the accompanying drawings includes an ink fountain body 11, and stoppers 13 are installed on both sides of the ink fountain body 11, and a spring leaf 14 is installed at the end of the stopper 13, so that the stopper is close to the ink fountain roller 1, and the stopper The front end of the block 13 is provided with an arc groove matching with the ink fountain roller 1, and the outer side of the stop block 13 is provided with a fixed block 15 installed on the ink fountain body 11, and an elastic push post 16 is installed on the fixed block 15 to push against the block. Block 13, to prevent the ink from leaking from both sides, the two ends of the ink fountain body 11 are provided with support shafts 18 connected to the wallboard of the printing machine, and a positioning pillar 17 is also installed on the ink fountain body 11 near the position of the support shaft 18, It is used to adjust the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com