Stiffened variable cross section high-pressure jet grouting pile antiskid wall construction method

A technology of high-pressure rotary grouting piles and construction methods, which can be applied to sheet pile walls, excavation, and foundation structure engineering, etc., can solve problems such as poor anti-sliding effect of sliding zone soil, affecting anchoring strength of anchor cables, loss of prestress of anchor cables, etc. Achieve stable anti-slip effect, good anti-slip effect, and improve anti-slip ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

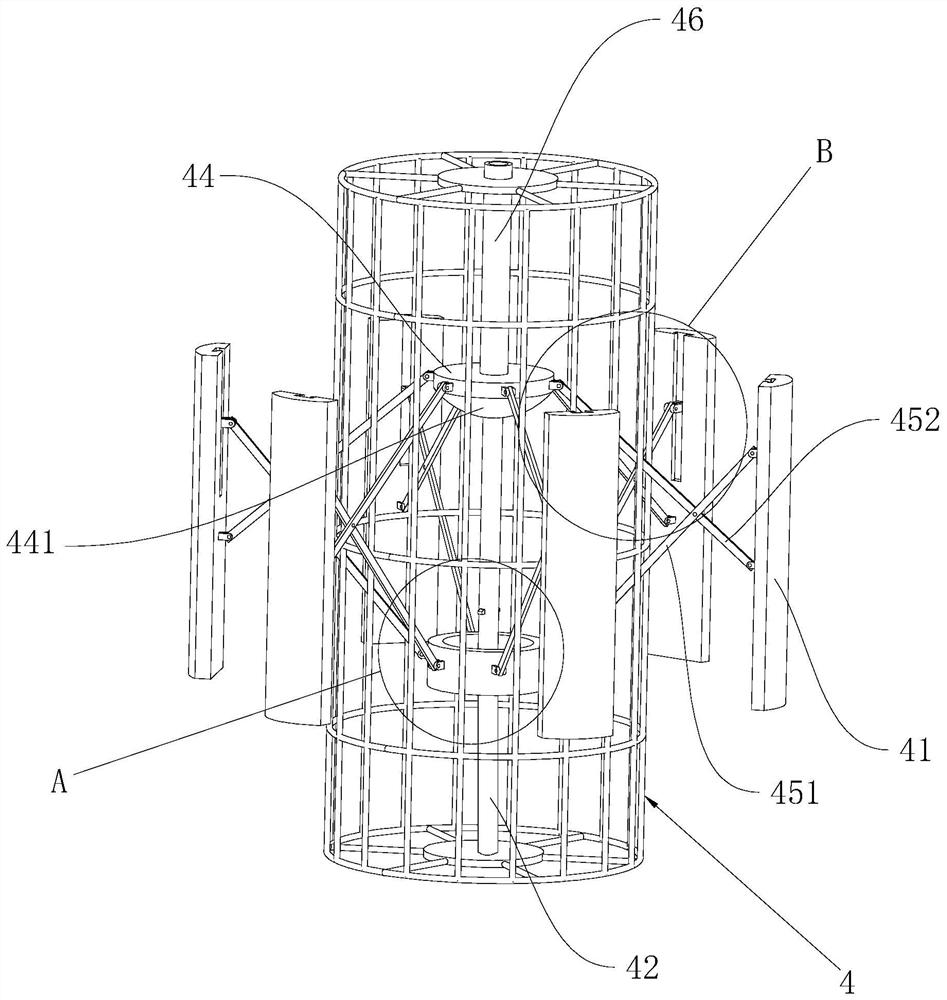

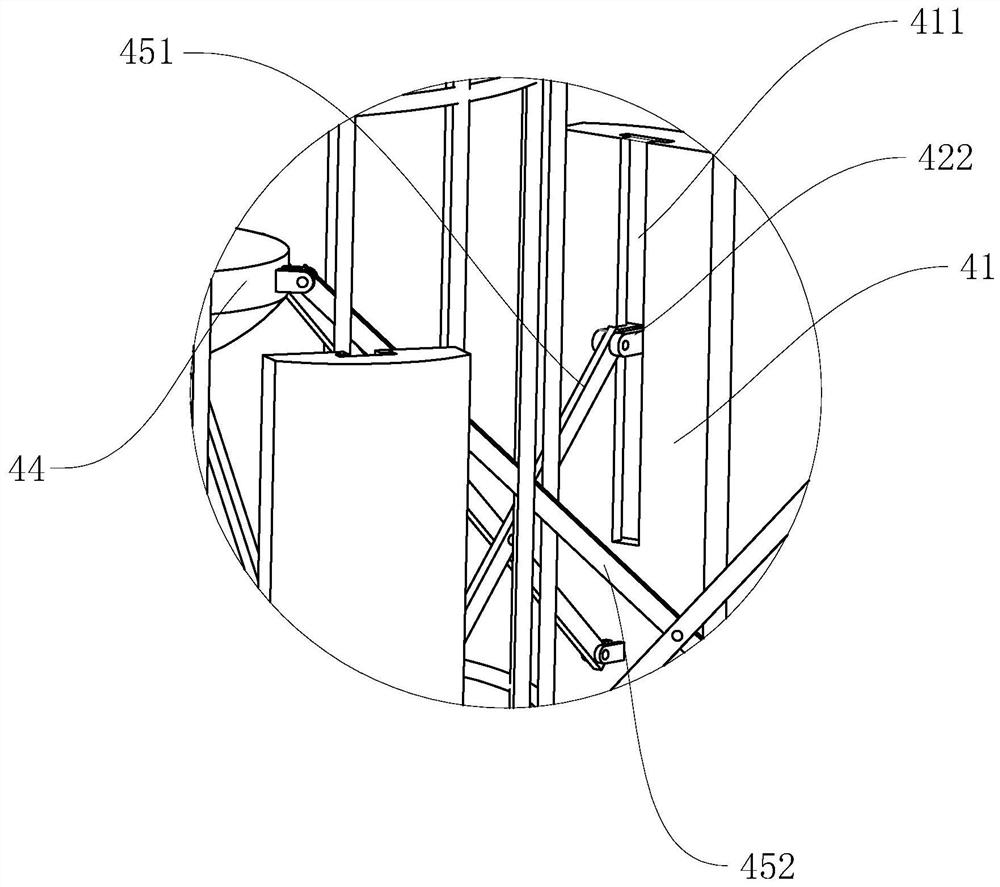

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

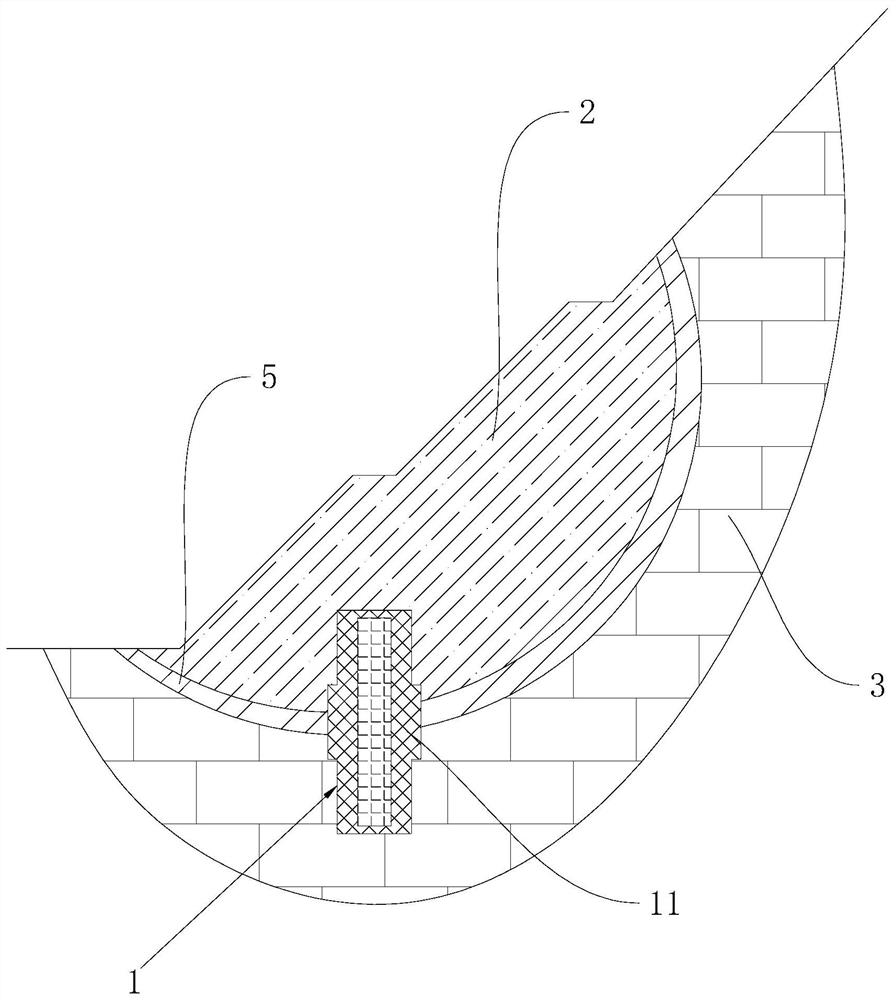

[0038] refer to figure 1 , which is a construction method for the anti-sliding wall of a rigid variable cross-section high-pressure jet grouting pile 1 disclosed by the present invention, comprising the following steps:

[0039] S1. Landslide on-site investigation, surveying and mapping and engineering geological survey, analyze and judge the cause of slope instability and controlling factors; determine the position, thickness, shape and physical and mechanical indicators of the sliding zone soil 5;

[0040]S2. Carry out slope stability analysis according to the site survey, determine the predetermined spatial position of the anti-slide pile wall, determine the number of anti-slide pile walls and the embedding depth;

[0041] S3, the anti-sliding wall is piled, and the predetermined position is drilled and the high-pressure rotary grouting pile 1 is formed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com