Steel bar welding platform for construction engineering

A welding platform and construction engineering technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unable to accelerate the cooling of steel bars, and cannot remove rust on the surface of steel bars, so as to achieve the effect of accelerated cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

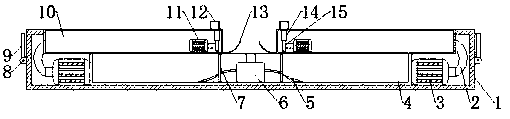

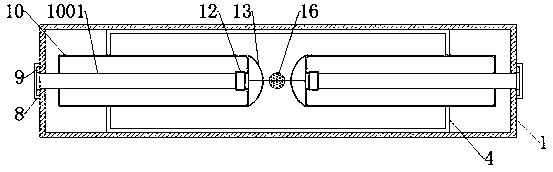

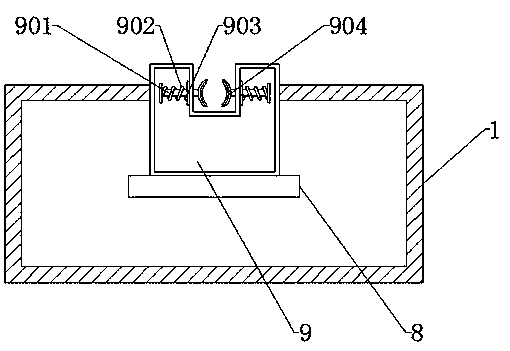

[0029] refer to Figure 1-6 , a steel bar welding platform for construction engineering, comprising a main body 1, the bottom inner wall of the main body 1 is fixedly connected with a water tank 4, the middle part of the bottom inner wall of the water tank 4 is connected with an atomizing nozzle 6 by bolts, and the top of the main body 1 is provided with a bar-shaped Through holes, the main body 1 is fixedly connected with two fixed boxes 10 at the strip-shaped through holes, the bottom inner walls of the two fixed boxes 10 are equipped with motors 11 through bolts, and the top side of the fixed boxes 10 is equipped with a second One through hole, the fixed box 10 is provided with a grinding structure at the first through hole, the grinding structure includes a fixed plate 1401, the fixed plate 1401 is fixedly connected with the fixed box 10, and one side of the fixed plate 1401 is provided with a toothed ring 14, the toothed ring A metal wire 1402 is fixedly connected to the ...

Embodiment 2

[0037] refer to Figure 7 , a steel bar welding platform for construction engineering. Compared with Embodiment 1, in this embodiment, in order to facilitate the handling and movement of the device, the bottom of the main body 1 is provided with four grooves, and the main body 1 is fixedly connected to the grooves. The second rotating shaft 17, the outer wall of the second rotating shaft 17 is fixedly connected with the rotating rod 18, and the bottom end of the rotating rod 18 is fixedly connected with the wheel 19, the rotation of the rotating rod 18 can be controlled by the second rotating shaft 17, thereby the wheel 19 can be controlled shrinkage.

[0038] When in use, first turn on the power, start the motor 11, the rotation of the motor 11 drives the gear 15 to rotate, the gear 15 drives the gear ring 14 to rotate, the gear ring 14 rotates to drive the metal wire 1402 to rotate, and the rotation of the gear ring 14 can drive the fixed cylinder 1403 to rotate , the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com