Hair iron

a hair iron and cutoff technology, applied in the field of hair irons, can solve the problems of high-temperature steam trapped along the periphery, difficult to disassemble hair irons into components, poor durability, etc., and achieve the effects of improving the steam cutoff property of the void space, facilitating disassembly and assembly, and improving the steam cutoff property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] An embodiment of the present invention is explained according to the drawings.

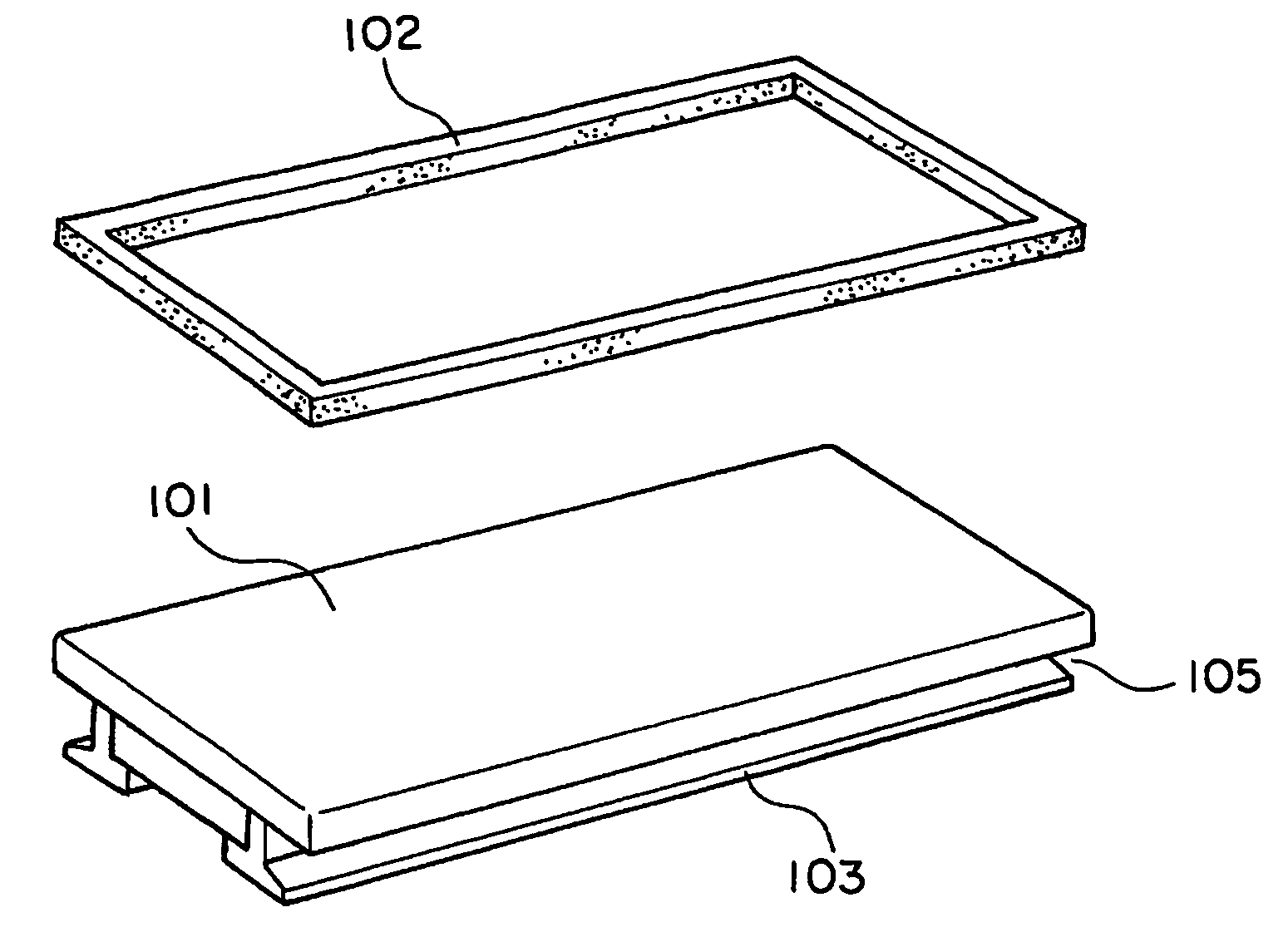

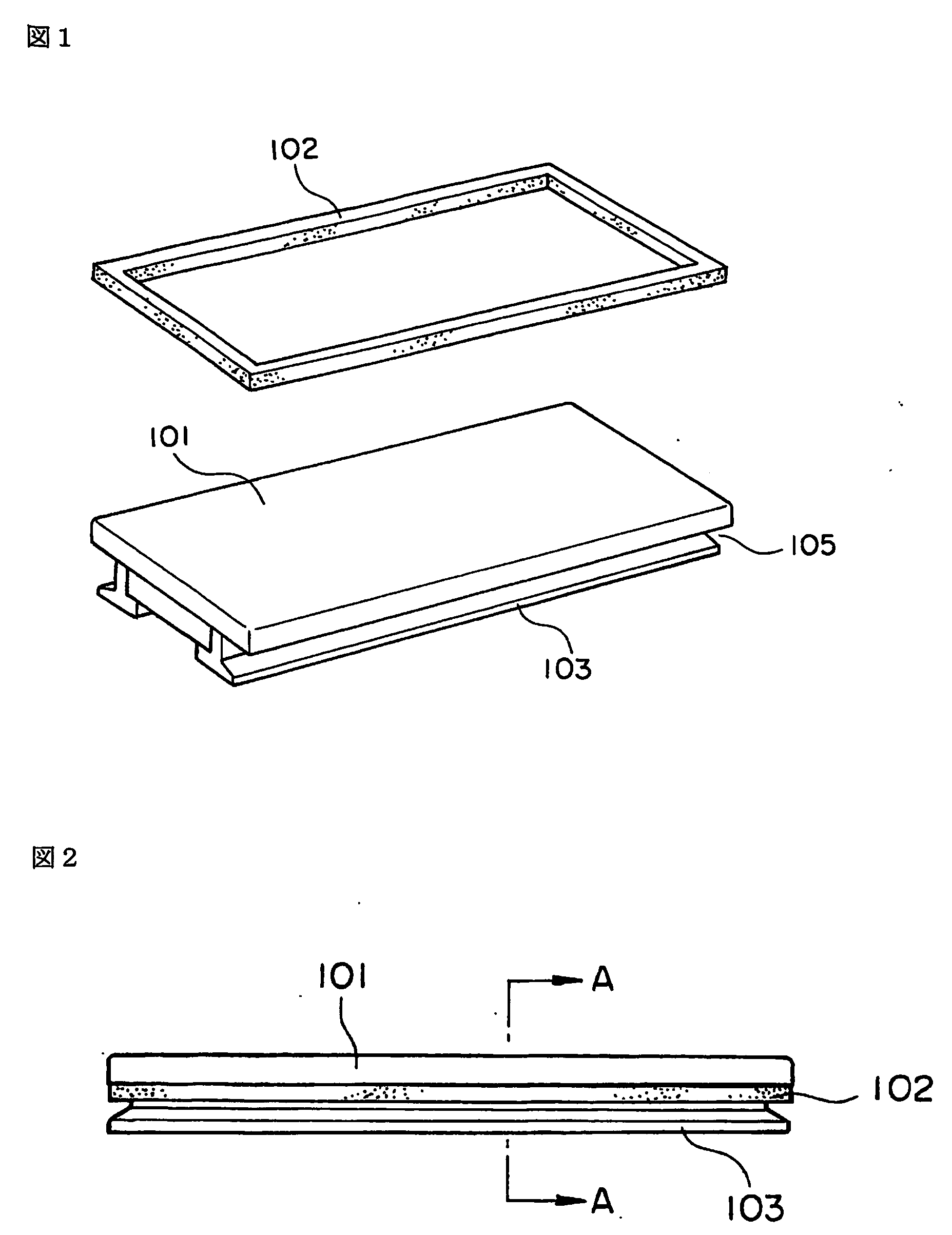

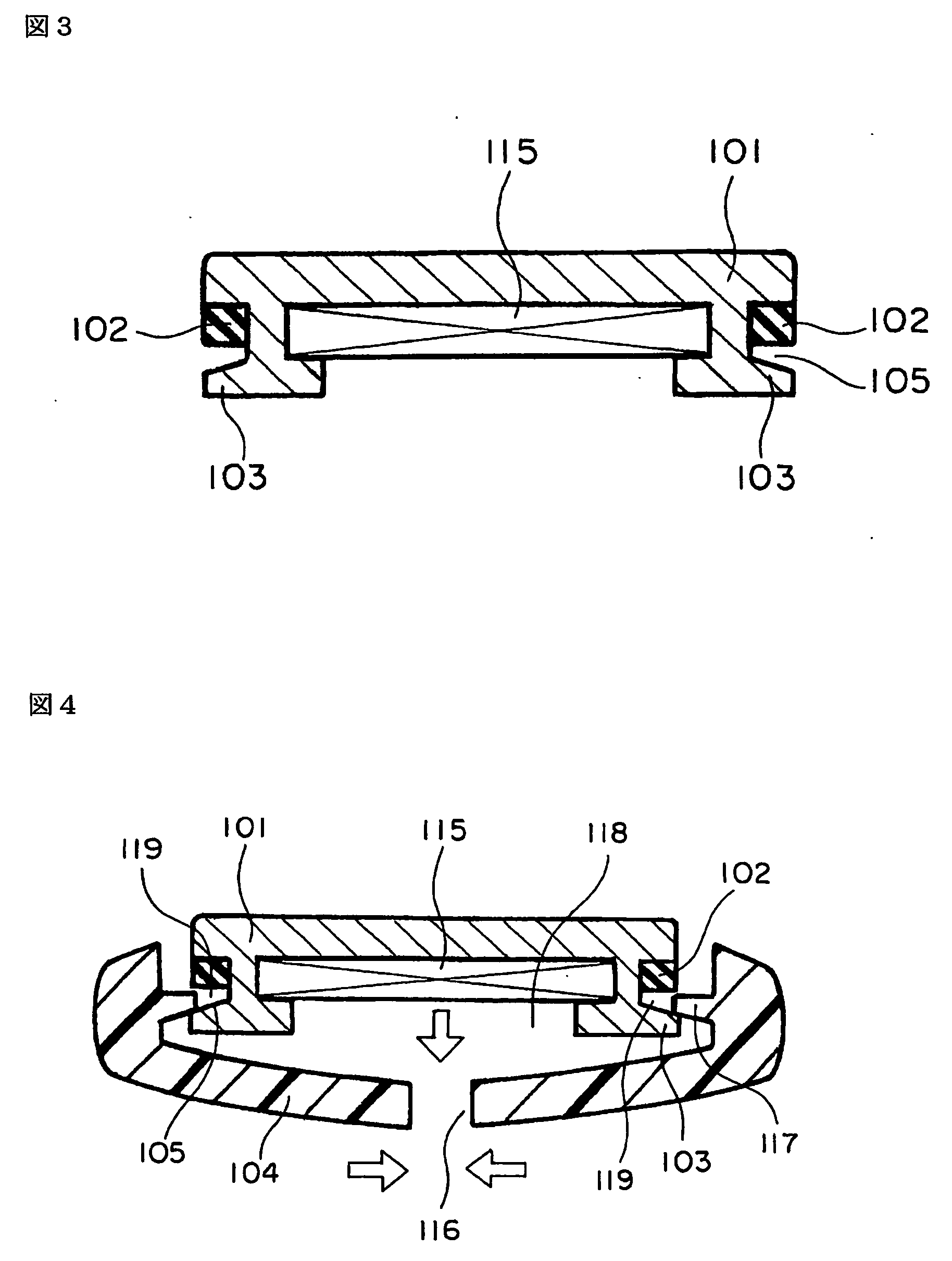

[0058]FIG. 1 shows the heating plate of the V-shaped hair iron proposed by the present invention and the gasket fitted to the heating plate. FIG. 2 is a side view of the gasket-fitted heating plate, while FIG. 3 provides a cross-section view of the gasket-fitted heating plate (cross-section view of the section indicated by the arrows in FIG. 2). FIG. 4 shows a condition before the gasket-fitted heating plate is installed on the iron body, while FIG. 5 shows a condition after the gasket has been fully engaged with the iron body. FIG. 6 shows a side view of the hair-sandwiching arm constituting the hair iron proposed by the present invention, while FIG. 7 shows a cross-section view taken along line B-B of FIG. 6. FIG. 8 is a perspective view of a conventional hair iron of V-shaped, hair-sandwiching arm type, while FIG. 9 is a cross-section view showing how a heating plate is supported on a convention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com