Heat insulation-cold stimulated-shell of pipe exterior cold combined gas solid phase fixed bed catalyst chamber

A catalytic reactor and combined technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of affecting the space-time yield of the catalyst, loss of activity of the catalyst, affecting the service life, etc. The effect of longevity and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

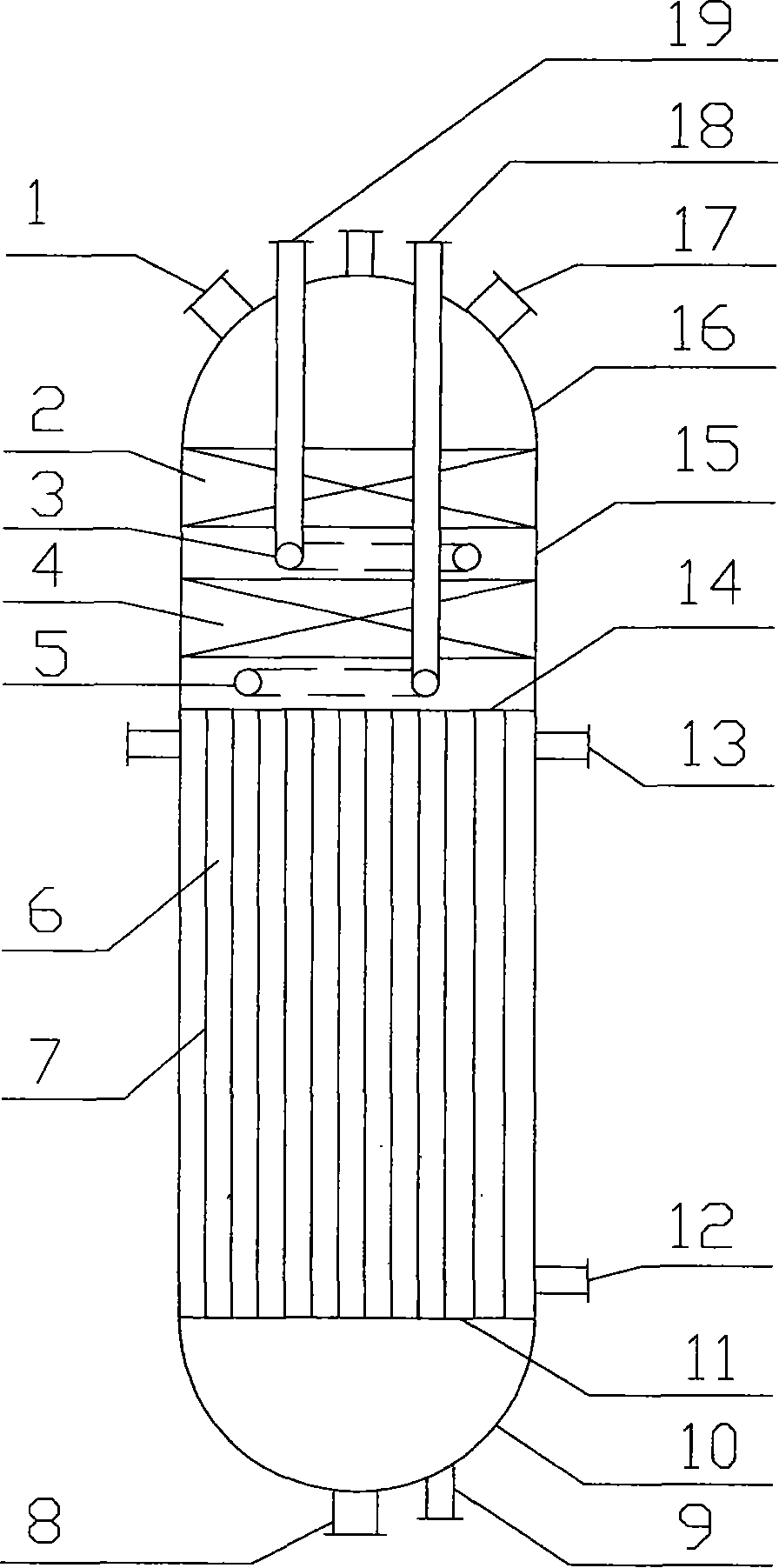

[0027] Hereinafter, specific embodiments of the present invention will be given with reference to the drawings, but the present invention is not limited to the following embodiments.

[0028] A combined gas-solid phase fixed-bed catalytic reactor of adiabatic-cold shock-tube-shell external cooling, consisting of a cylinder 15, an upper head 16, an adiabatic reaction section, a tube-shell outer cooling section, and a lower head 10. A gas inlet 1 and a manhole 17 are arranged on the head 16, and a gas outlet 8 and a catalyst discharge port 9 are arranged on the lower head 10 of the reactor.

[0029] The inner diameter of the cylinder 15 is 3.8 meters, and the upper part is an adiabatic reaction section, which is provided with two adiabatic layers: a first adiabatic layer 2 and a second adiabatic layer 4, the first adiabatic layer 2 is arranged above the second adiabatic layer 4; After the first heat insulation layer 2, there is a cold shock of raw material gas, which is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com