Preparing method for coating with controllable crosslinking degree

A technology of cross-linking degree and coating, applied in the field of ion chemical vapor deposition, can solve the problems of coating swelling and peeling, many linear components of coating, restricting the protection ability of substrates, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

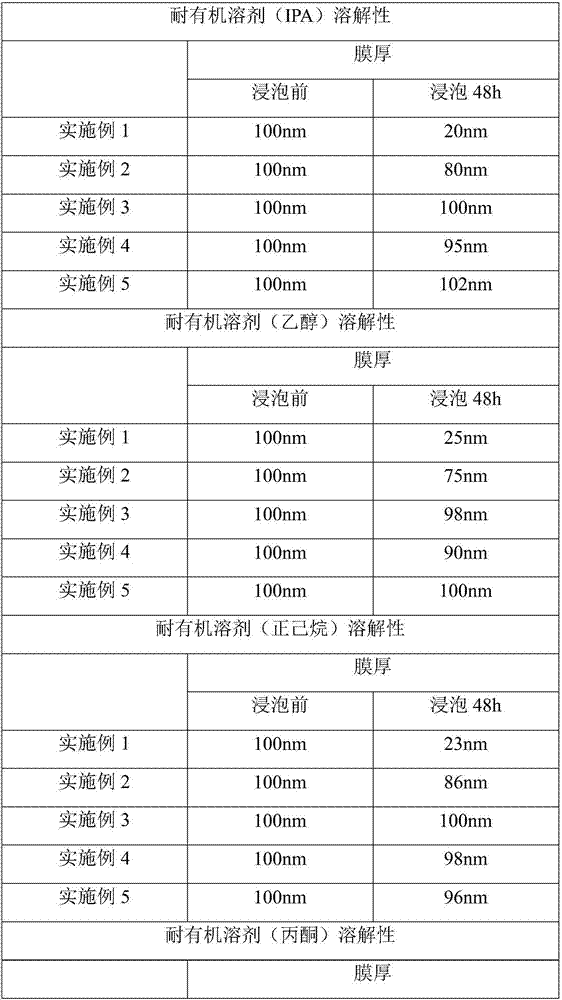

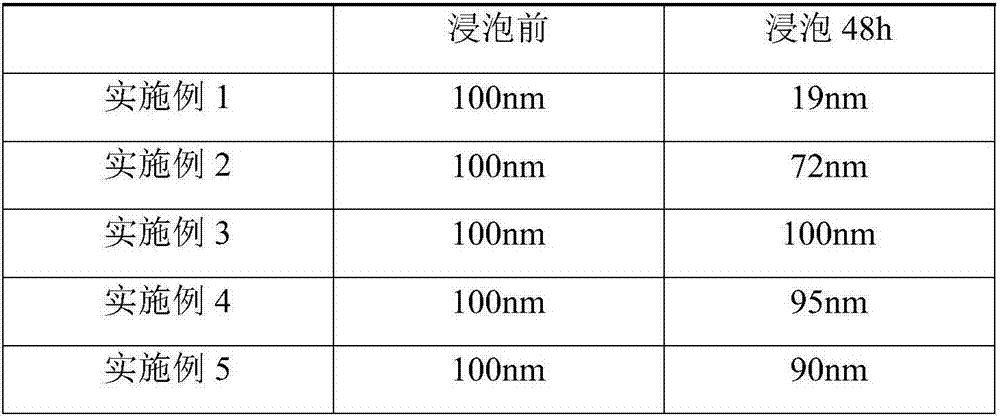

Examples

Embodiment 1

[0033] A method for preparing a coating with a controllable degree of crosslinking, characterized in that it mainly includes the following steps:

[0034] (1) Place the base material in the reaction chamber of the plasma chamber, the base material is a solid material, the solid material is an electronic component, and the reaction chamber is continuously evacuated, and the vacuum degree in the reaction chamber is evacuated to 10 Millitorr, feed nitrogen, provide a stable plasma environment, feed nitrogen flow rate of 5 sccm;

[0035] The volume of the plasma chamber is 50 liters, and the temperature of the plasma chamber is controlled at 30°C.

[0036] (2) Introduce monomer vapor, turn on plasma discharge, and carry out chemical vapor deposition;

[0037] Described monomer steam is:

[0038] A mixture of a monofunctional unsaturated fluorocarbon resin and a polyfunctional unsaturated hydrocarbon derivative, the monofunctional unsaturated fluorocarbon resin is 1H, 1H, 2H, 2H-...

Embodiment 2

[0044] The basic process steps of this embodiment are the same as those of Example 1, and the different process parameters are as follows:

[0045] 1. In step (1), the vacuum in the reaction chamber is evacuated to 50 millitorr, and an inert gas is introduced; the base material is a solid material, and the solid material is an electrical component. The volume of the plasma chamber is 200L, and the temperature of the plasma chamber is controlled at 40° C.; the flow rate of the inert gas is 50 sccm, and the inert gas is helium.

[0046] 2, the monomer vapor that feeds in the step (2) is:

[0047] A mixture of a monofunctional unsaturated fluorocarbon resin and a multifunctional unsaturated hydrocarbon derivative, the monofunctional unsaturated fluorocarbon resin is 2-perfluorooctyl ethyl acrylate, and the multifunctional The unsaturated hydrocarbon derivative is diethylene glycol divinyl ether, and the mass percentage of the polyfunctional unsaturated hydrocarbon derivative in th...

Embodiment 3

[0053] The basic process steps of this embodiment are the same as those of Example 1, and the different process parameters are as follows:

[0054] 1. In step (1), the vacuum in the reaction chamber is evacuated to 200 millitorr, and an inert gas is introduced; the base material is a solid material, and the solid material is clothing. The volume of the plasma chamber is 1000L, and the temperature of the plasma chamber is controlled at 60° C.; the flow rate of the inert gas is 300 sccm, and the inert gas is argon.

[0055] 2, the monomer vapor that feeds in the step (2) is:

[0056] A mixture of a monofunctional unsaturated fluorocarbon resin and two polyfunctional unsaturated hydrocarbon derivatives, the monofunctional unsaturated fluorocarbon resin is 2-(perfluorobutyl) ethyl acrylate, the The two kinds of multifunctional unsaturated hydrocarbon derivatives are diethylene glycol divinyl ether and ethylene glycol diacrylate, and the mass percentage of multifunctional unsatura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com