Metal magnetic-acceleration sand-blasting plating equipment adopting metal plating electro-thermal process

An electrothermal method, metal technology, applied in metal processing equipment, abrasive jet machine tools, used abrasive treatment devices, etc. It can improve the quality of processing, facilitate storage and handling, and ensure the quality of coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

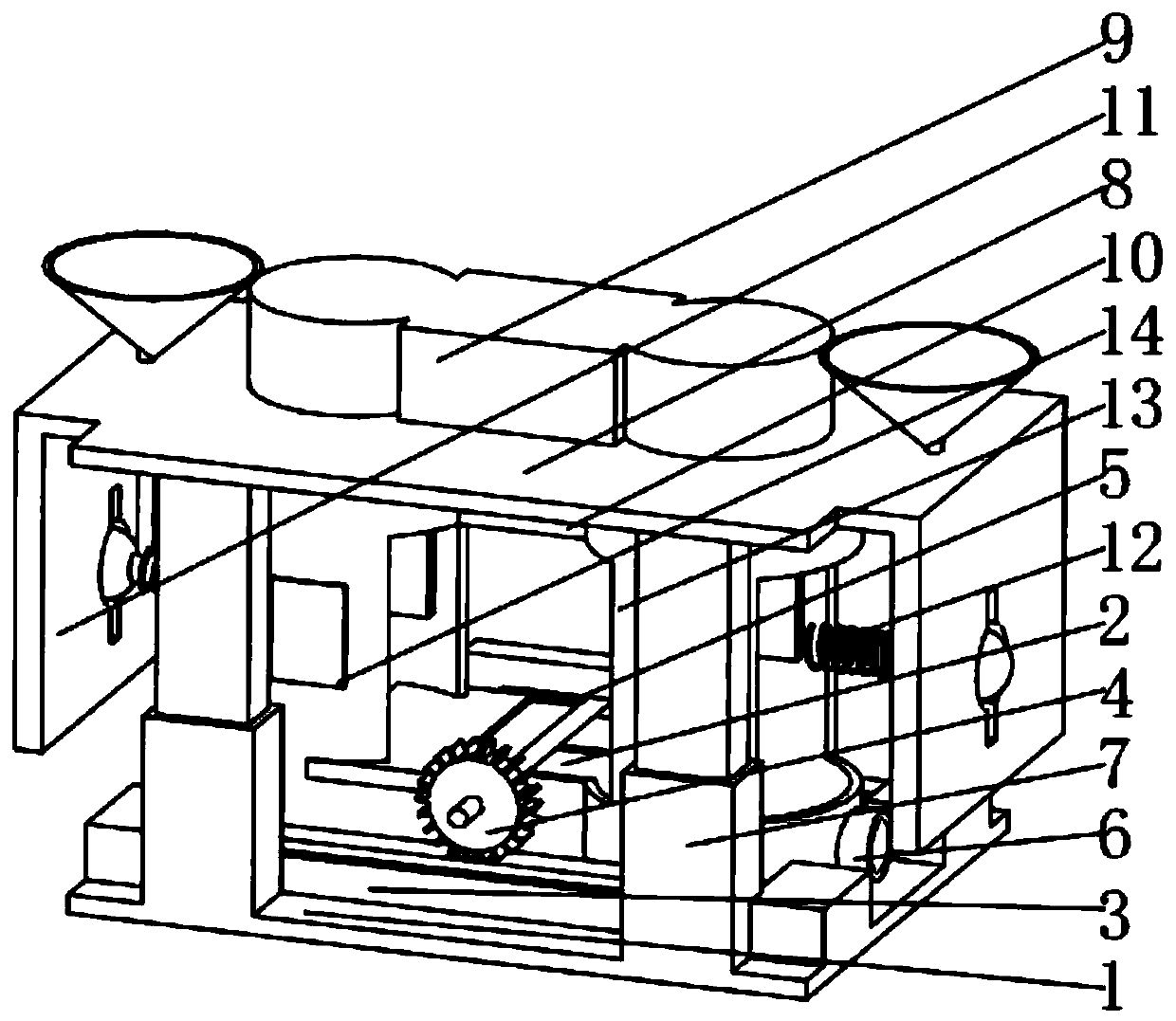

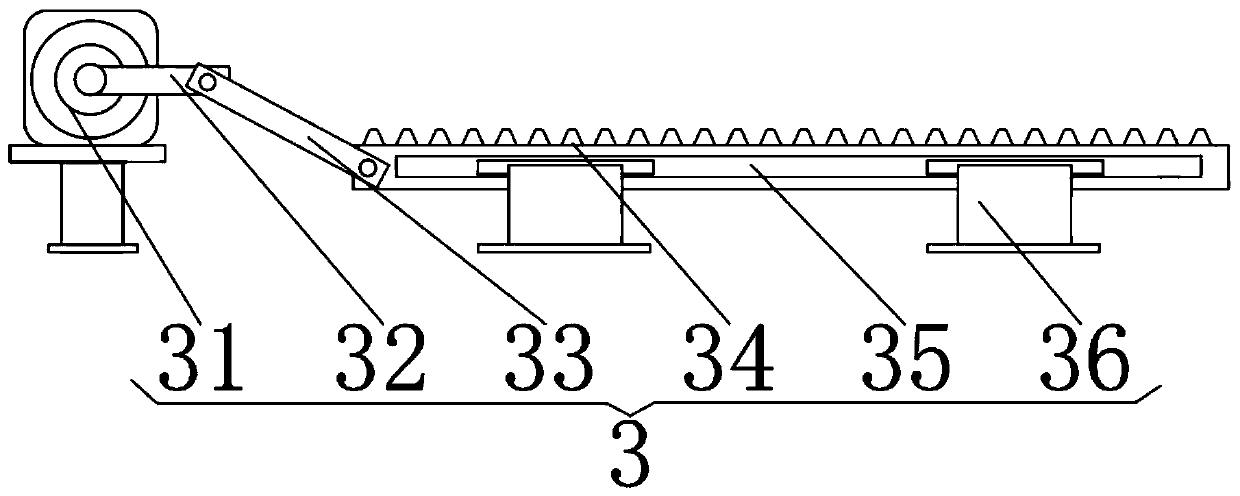

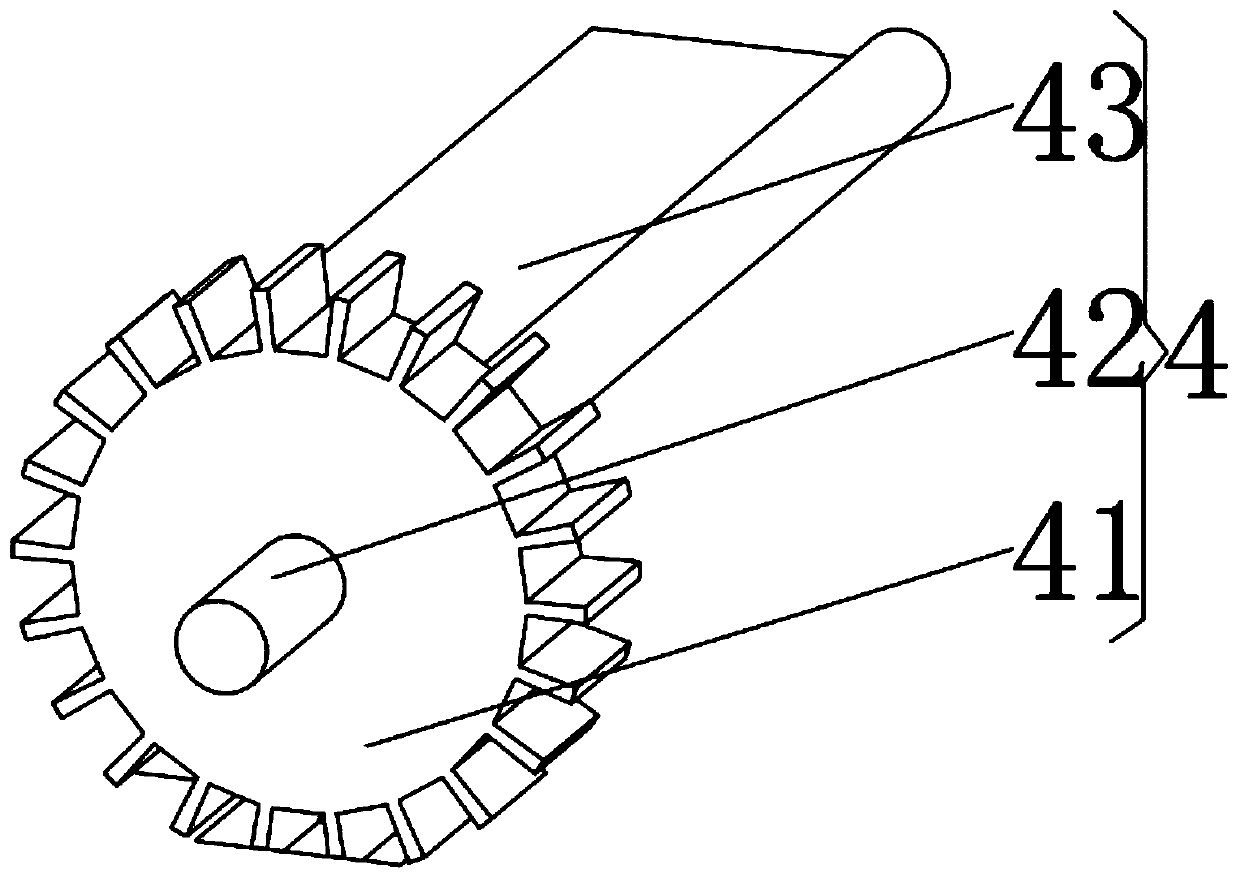

[0036] like Figure 1-5 As shown, a kind of metal plating electrothermal method metal magnetic acceleration sandblasting plating equipment proposed by the present invention includes a base 1, the middle position of the top of the base 1 is fixedly connected with a plating circular groove 2, and the top of the base 1 is located in the plating circular groove 2 The front is fixedly connected with the rotating mechanism 3, and the top of the rotating mechanism 3 is meshed with the installation mechanism 4, and the end of the installation mechanism 4 away from the rotating mechanism 3 is movably connected with the track groove 5, and the middle and lower positions of the outer walls of the plating circular groove 2 are provided with a drain The holes 6 and the four corners of the top of the base 1 are fixedly connected with an adjustment mechanism 7, and the side of the adjustment mechanism 7 away from the base 1 is fixedly connected with a protective top plate 8, and the middle po...

Embodiment 2

[0038] like Figure 1-8 As shown, on the basis of Embodiment 1, the sandblasting mechanism 11 proposed by the present invention includes a connecting guide plate 111, an extruding mechanism 112 is arranged in the middle of the connecting guide plate 111, and an inflating ball 113 is arranged in the middle of the inner cavity of the extruding mechanism 112. The side of the balloon 113 close to the limiting circular groove 10 is connected with a jet pipe 114, the top of the jet pipe 114 is connected with a sand inlet pipe 115 on the side close to the balloon 113, and the inner surface of the balloon 113 is fixed on both the front and the back. A rebound magnet 116 is attached. The extruding mechanism 112 includes an outer restricting guide plate 1121, the inner surface of the outer restricting guide plate 1121 is movably connected with a rotating plate 1122 on the side away from the limiting circular groove 10, and the side of the rotating plate 1122 close to the limiting circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com