Method for determining wing-shaped oblique-flow cooling fan of automobile engine

A technology for automotive engines and cooling fans, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as large deviations in design results, long design change cycles, and unreasonable distribution of optimal flow rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

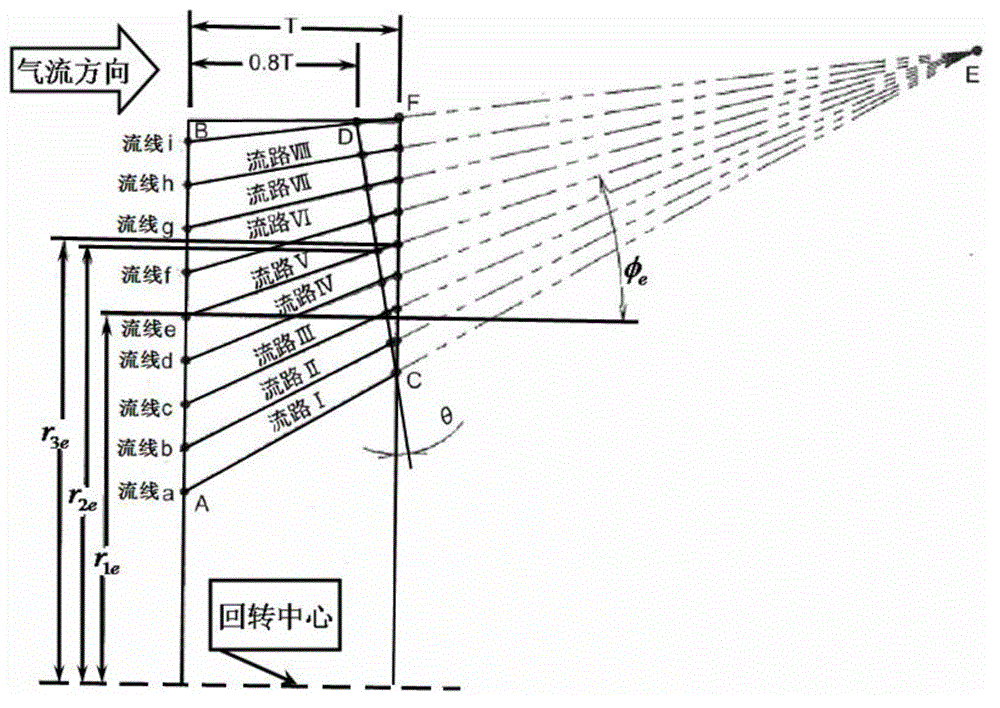

[0142] Such as Figure 4 As shown, it is a schematic diagram of the front structure of the airfoil oblique flow cooling fan of the automobile engine of the present invention. The shape of the blades is complex, and a plurality of blades are arranged on a cylindrical shaft disk, sucking air from the axial direction, and then to the oblique rear or radial direction blow out. Combining the advantages of centrifugal fans and axial flow fans, it is between centrifugal and axial flow within a certain specific speed range. It has the advantages of large flow and high pressure, and has the large flow coefficient, high efficiency and high efficiency of axial flow fans. Centrifugal fans have the advantages of high pressure coefficient and wide working range, especially suitable for compact car engine compartments, and are ideal cooling fans.

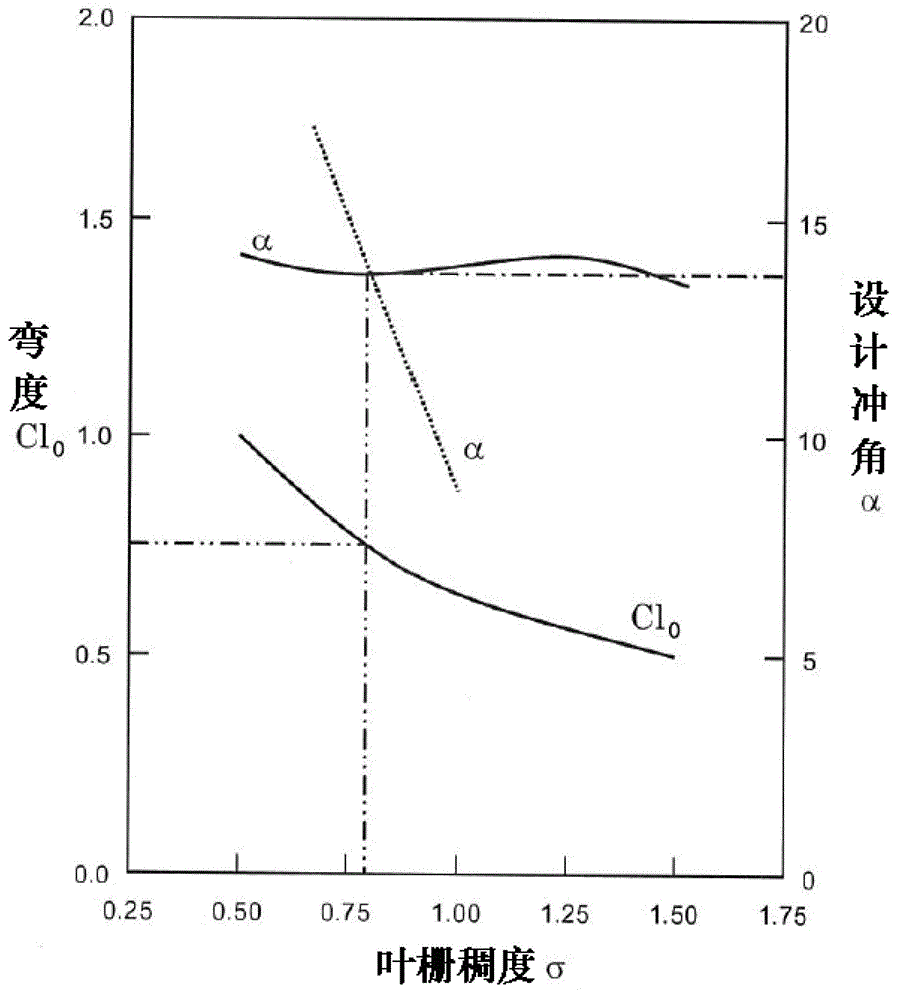

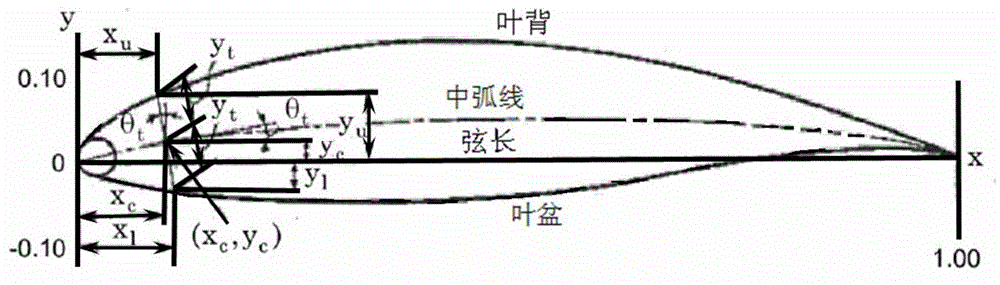

[0143] The method for determining the oblique flow cooling fan of the automobile engine airfoil of the present invention is implemented accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com