Simple flexible pressure equalizing pad for hot press molding of composite material and application thereof

A composite material and thermoforming technology, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of uneven pressure on parts, complex manufacturing process, long preparation cycle, etc. The effect of surface smoothness, low production cost, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

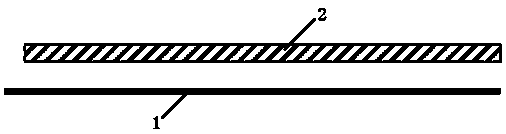

[0024] This implementation is a simple and flexible pressure equalizing pad used for hot pressing of composite materials, such as figure 1 As shown, it includes a release cloth layer 1 and a fiber cloth layer 2, and the release cloth layer 1 is laid on the fiber cloth layer 2 to form a simple flexible pressure equalizing pad 3. Wherein, the release cloth layer 1 is a single-sided rubberized PTFE release cloth, and the rubberized surface is laid on the fiber cloth layer 2; the fiber cloth used in the fiber cloth layer 2 is dry polyester peelable cloth. In some embodiments, a separate polyester peelable cloth can be used to directly cover the prepreg of the composite material, but because it is easy to absorb resin, the thickness of the molded part becomes thinner and the composite material is reduced. Qualified rate. In this implementation, a layer of PTFE release cloth is added on the side where the dry polyester peelable cloth is in contact with the composite prepreg, which ef...

Embodiment 2

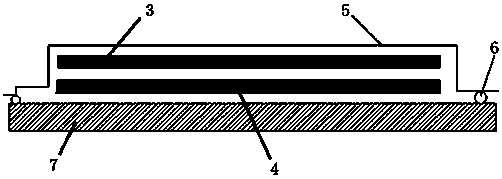

[0028] This embodiment provides an application of the simple flexible pressure equalizing pad described in Embodiment 1, which is mainly used to assist the forming process of a composite material part autoclave, and includes the following steps:

[0029] 1) Covering the pressure equalization pad: spread the release cloth layer 1 of the simple flexible pressure equalization pad 3 described in Example 1 on the composite preformed part 4 with one side facing down;

[0030] 2) Cutting: According to the profile and size of the composite material pre-formed part 4, cut the simple flexible pressure equalizing pad 3 described in step 1 at the corners of the part, the curvature change area, etc., and use pressure-sensitive tape for splicing Fixed to ensure that the simple flexible pressure equalizing pad 3 can completely cover the surface of the composite material preformed part 4;

[0031] 3) Encapsulation: Use the vacuum bag 5 and the sealing tape 6 to encapsulate the composite material pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com