Cable insulating layer specimen cutting device and cutting method

A technology for cable insulation and cutting devices, applied in the direction of sampling devices, etc., can solve the problems of sample waste, limited surface smoothness of samples, and inability to investigate the difference of insulating layer materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

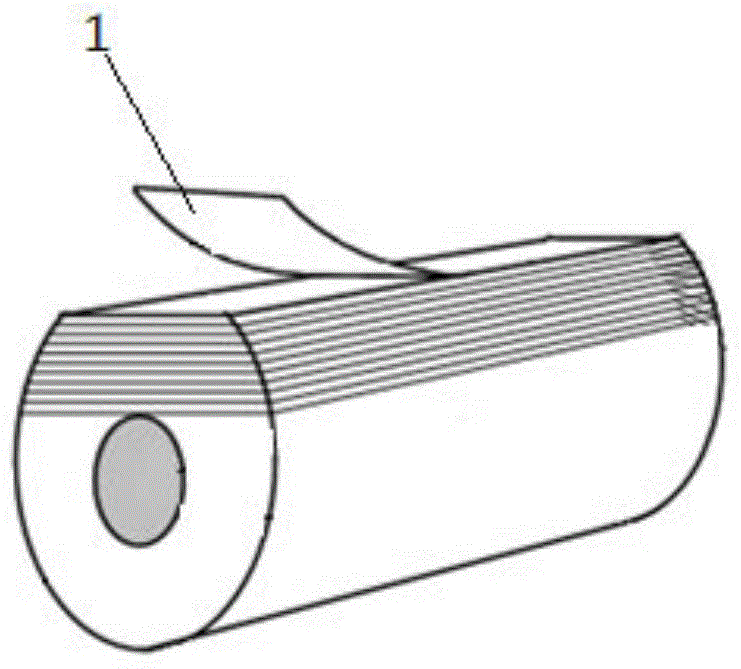

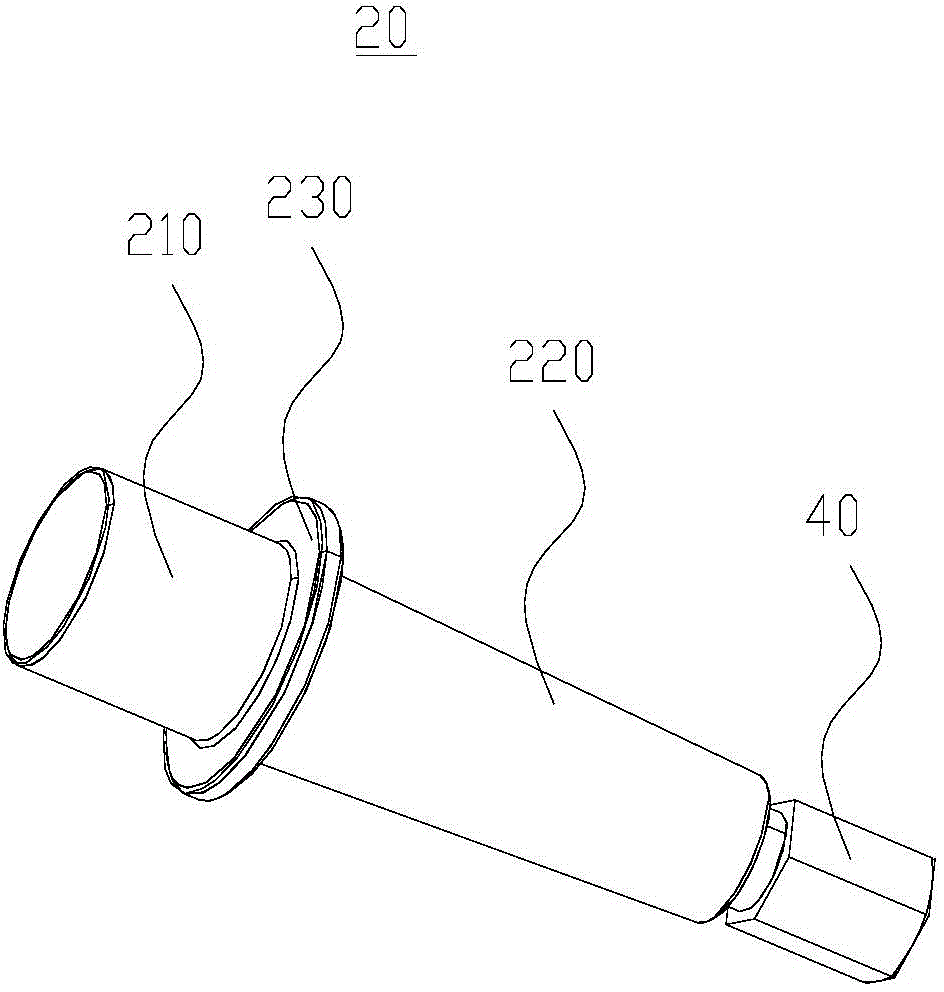

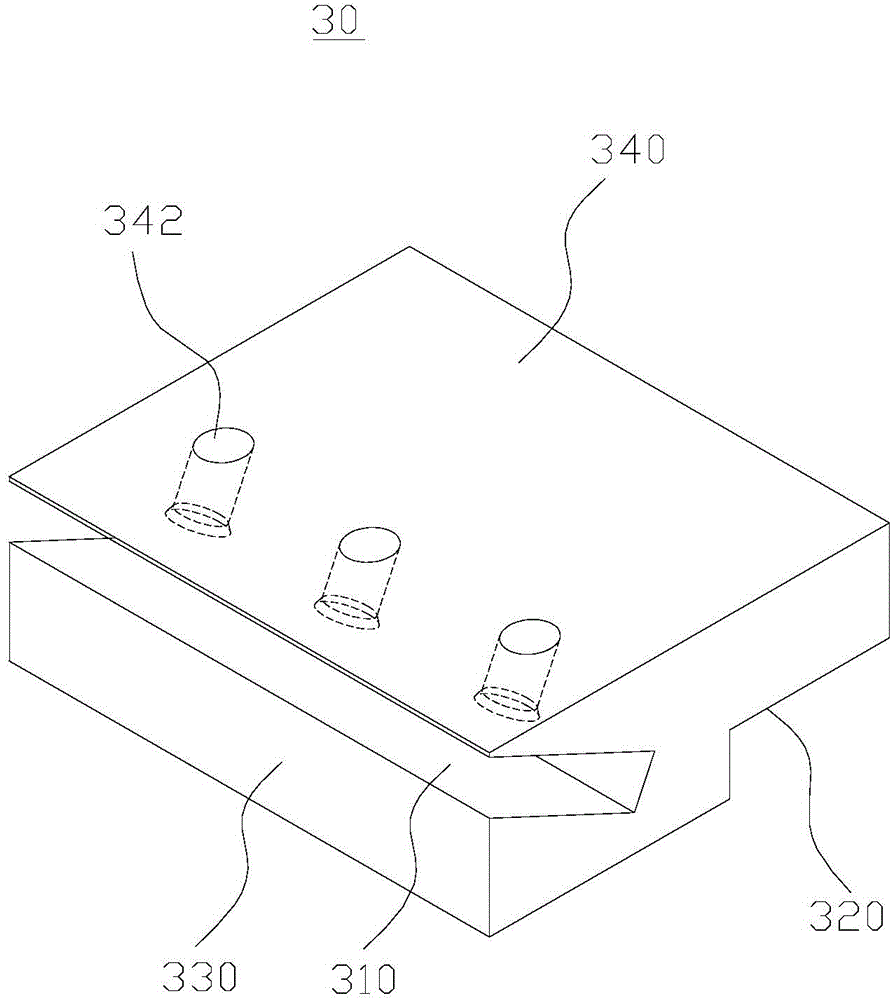

[0033] Such as Figure 2 to Figure 4 As shown, a cable insulation layer sample cutting device includes a blade 10, a fixed shaft 20, and a fixed base 30. The fixed shaft 20 includes a first installation section 210 and a second installation section 220 connected to each other. The installation section 210 is connected to the rotating shaft of the lathe, the cable insulation layer sample 2 is set on the second installation section 220, the fixed base 30 is installed on the lathe, and the fixed base 30 is provided with a knife groove 310 matching the blade 10 , the blade 10 is fixedly installed in the groove 310 , and the cutting edge of the blade 10 is parallel to the axial direction of the fixed shaft 20 .

[0034] By setting the fixed shaft 20, the cable insulation layer sample 2 is arranged on its second installation section 220, and the cable insulation layer sample 2 does not move or rotate relative to the fixed shaft 20, and its first installation section 210 and the rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com