Method for coloring pattern or character on surface of aluminum alloy material and product thereof

A technology of aluminum alloy material and surface pattern, which is applied in special artistic surface treatment, device for coating liquid on surface, process for producing decorative surface effect, etc. It can solve the problems of lack of texture, lack of change, monotony, etc. Maintain surface flatness, good quality, rich color change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

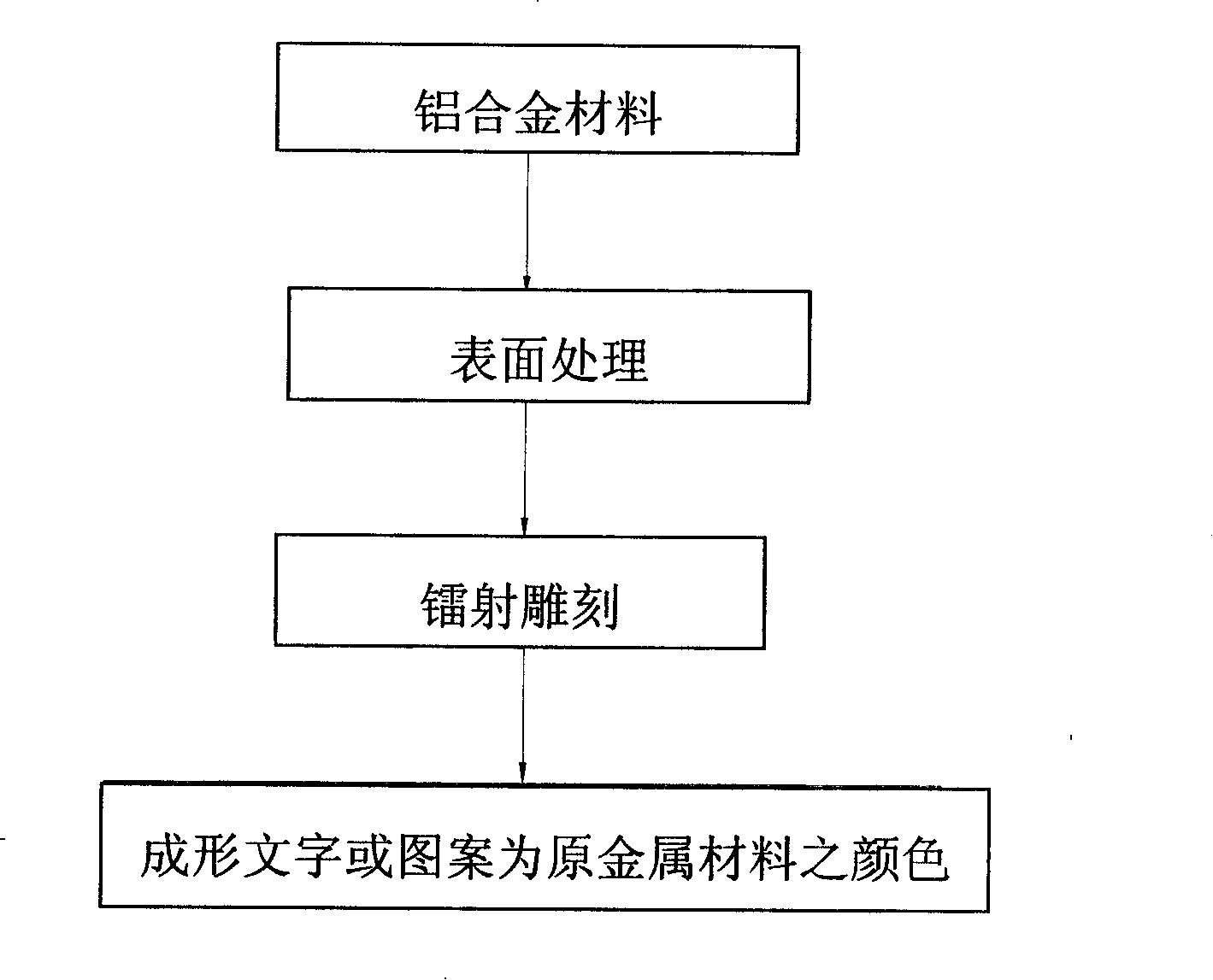

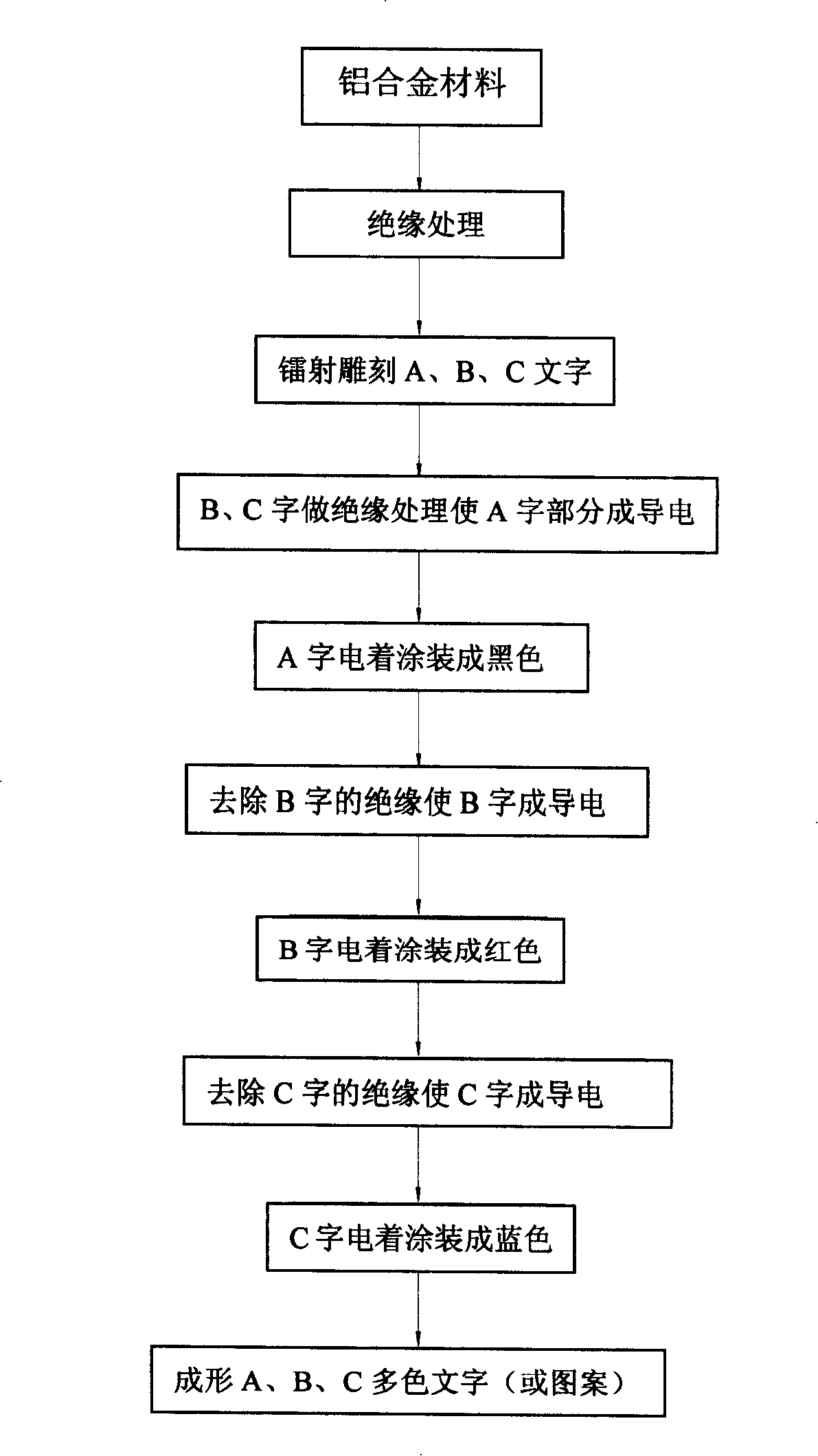

[0019] According to the surface pattern or text coloring method of the aluminum alloy material of the present invention, such as image 3 and Figure 4 As shown, the steps are as follows:

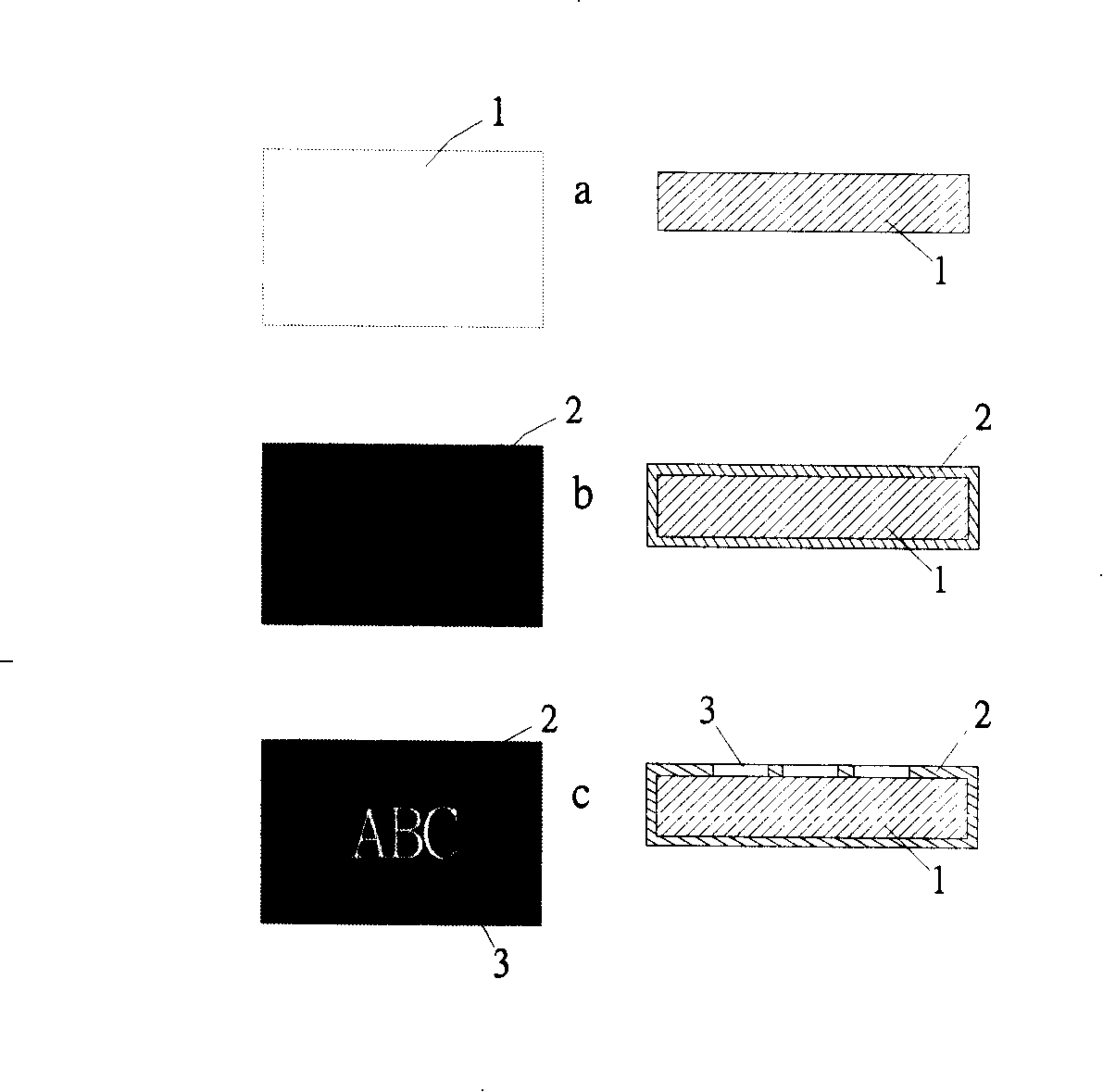

[0020] a. First, an aluminum alloy material 10 to be colored is subjected to insulation treatment, that is, the aluminum alloy material is insulated into a non-conductor, that is, an insulator by means of electro-deposition coating. Of course, at this time, the aluminum alloy material 10 will be Because of its surface forming an insulating layer 20 to change the primary color of the aluminum alloy material such as Figure 4 a with Figure 4 the changes shown in b;

[0021] b. Use laser engraving technology to engrave text or patterns 30 on predetermined parts of the surface of the aluminum alloy material 10, such as Figure 4 A, B, C and other characters shown in c, or such as Figure 5 The whale pattern 40, such as Figure 6 There are three descriptive characters 50, and the characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com