Method of manufacturing liquid crystal display panel

A technology for a liquid crystal display panel and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of high cost, reduced product yield, and cannot guarantee the surface flatness of glass substrates, and achieves high strength and avoids damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

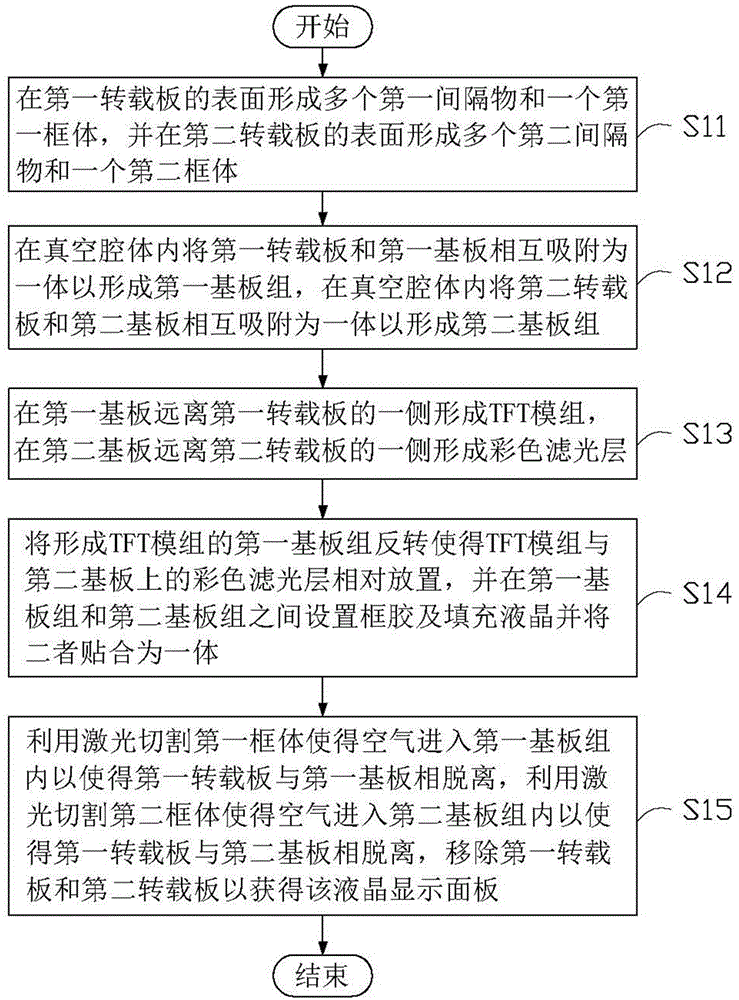

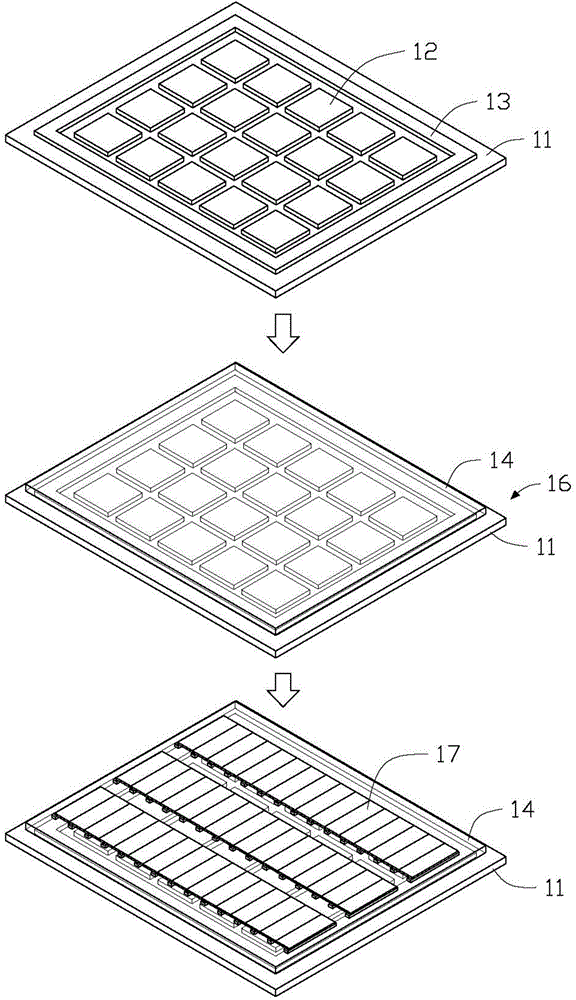

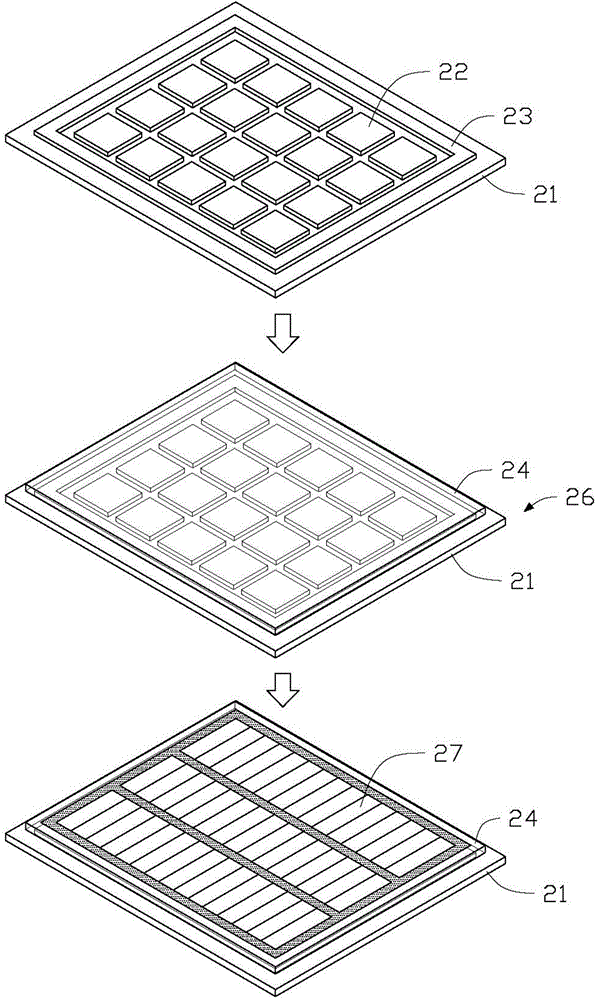

[0022] Please also refer to Figure 1 to Figure 5 , which is a flow chart of a method for manufacturing the liquid crystal display panel 10 in a preferred embodiment. Figure 2-Figure 4 for figure 1 The structure diagram corresponding to each process step shown, Figure 5 for Figure 4 A cross-sectional view of the first substrate group 16 and the second substrate group 26 along the V-V direction. In this embodiment, the liquid crystal display panel 10 is a thin film transistor (TFT-LCD) panel. In other alternative embodiments, the liquid crystal display panel 10 can also be an active matrix organic light emitting diode (AMOLED) panel.

[0023] Step S11 , forming a plurality of first spacers 12 and a first frame body 13 on the surface of the first transfer plate 11 , and forming a plurality of second spacers 22 and a second frame body on the surface of the second transfer plate 21 twenty three. The plurality of first spacers 12 are located in the first frame body 13 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com