Two-way stretching degradable film and preparation method thereof

A biaxially stretched and degradable film technology, which is applied to chemical instruments and methods, flat products, and other household appliances, can solve problems such as heat-sealing strength and surface smoothness, difficulty in degradation, and negative environmental impacts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

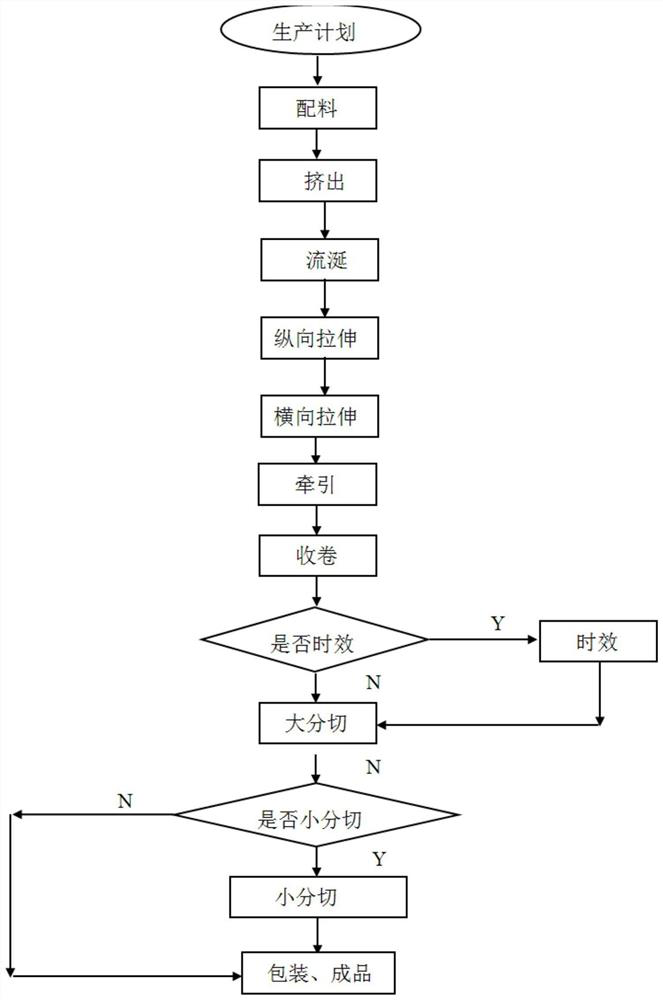

[0041] The present invention also provides a method for preparing the biaxially oriented degradable film described above, comprising the following steps:

[0042] A) extruding and blending the raw materials of layer A, layer B and layer C respectively according to the ratio of raw materials to obtain the blended material of layer A, the blended material of layer B and the blended material of layer C;

[0043] B) Three-layer co-extrusion of the A-layer blend material, B-layer blend material and C-layer blend material, followed by casting, longitudinal stretching and transverse stretching, to obtain a biaxially stretched degradable film.

[0044] In the present invention, the raw material formulations of the A layer, the B layer and the C layer are consistent with the raw material formulations of the A layer, the B layer and the C layer described above, and will not be repeated here.

[0045]In the present invention, the above-mentioned components are blended and extruded in a t...

Embodiment 1

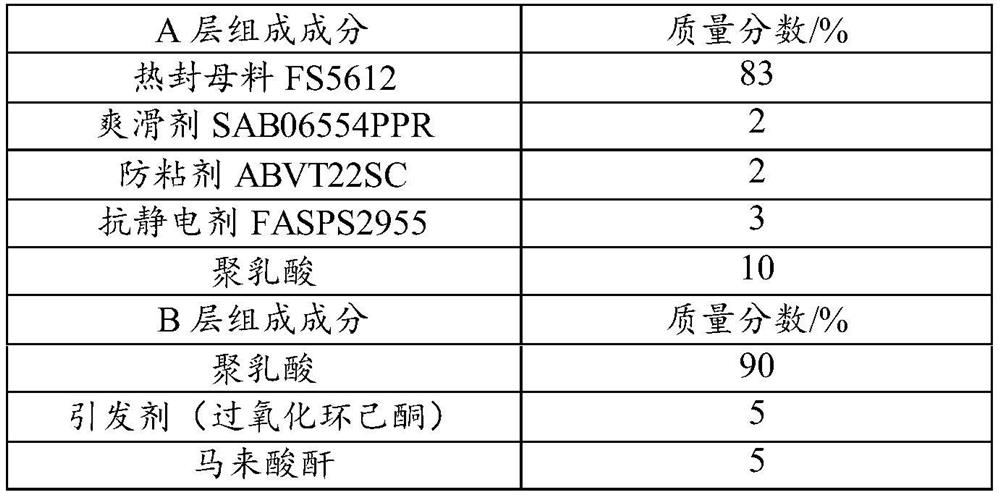

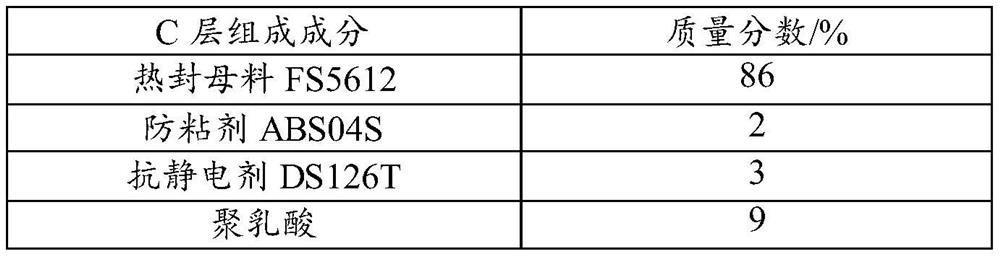

[0056] The composition of each layer is shown in Table 1:

[0057] Table 1

[0058] A layer composition Mass fraction / % Heat seal masterbatch FS5612 85 Slip agent SAB06554PPR 2 Antisticking agent ABVT22SC 3 Antistatic agent FASPS2955 5 polylactic acid 5 B layer composition Mass fraction / % polylactic acid 80 Initiator (tert-butyl peroxybenzoate) 5 maleic anhydride 15 C layer composition Mass fraction / % Heat seal masterbatch FS5612 88 Anti-sticking agent ABS04S 5 Antistatic agent DS126T 5 polylactic acid 2

[0059] Layer A: Blend the blend of anti-sticking agent ABVT22SC, slip agent SAB06554PPR, antistatic agent FASPS2955 and polylactic acid with heat-sealing masterbatch FS5612 in a twin-screw extruder at 190°C;

[0060] Layer B: under the action of an initiator, polylactic acid and maleic anhydride are blended in a twin-screw extruder at 190°C;

[0061] Layer C: Blend the blen...

Embodiment 2

[0064] Table 2

[0065] A layer composition Mass fraction / % Heat seal masterbatch FS5612 84 Slip agent SAB06554PPR 3 Antisticking agent ABVT22SC 3 Antistatic agent FASPS2955 3 polylactic acid 6 B layer composition Mass fraction / % polylactic acid 85 Initiator (tert-butyl peroxybenzoate) 3 maleic anhydride 12 C layer composition Mass fraction / % Heat seal masterbatch FS5612 87 Anti-sticking agent ABS04S 4 Antistatic agent DS126T 4 polylactic acid 5

[0066] Layer A: Blend the blend of anti-sticking agent ABVT22SC, slip agent SAB06554PPR, antistatic agent FASPS2955 and polylactic acid with heat-sealing masterbatch FS5612 in a twin-screw extruder at 190°C;

[0067] Layer B: under the action of an initiator, polylactic acid and maleic anhydride are blended in a twin-screw extruder at 190°C;

[0068] Layer C: Blend the blend of anti-sticking agent ABS04S, antistatic agent DS126T and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com