Preparation of baking finish for paint-drying bucket and spraying method

A technology for baking varnishes and barrels, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as low gloss and poor flame resistance, achieve excellent surface effects, huge market potential, and ensure smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

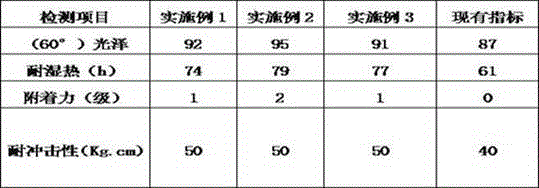

Examples

Embodiment 1

[0027] A method for preparing and spraying baking varnish for a paint bucket, comprising the following steps:

[0028] (1) Ingredients

[0029] Accurately weigh each raw material in turn according to the formula of primer and pearlescent paint;

[0030] (2) pre-mixed

[0031] The prepared water-based resin and amine neutralizer are pre-mixed with a mixer, the time of pre-mixing is 30min, the rotating speed of the mixer is 300r / min, the composition and proportioning of the primer ingredients are water-based resin 40, amino resin 5 , iron oxide red 2, iron oxide yellow 3, amine neutralizer 2, wetting agent 0.3, dispersant 0.3, flame retardant 0.1, epoxy resin 5, defoamer 0.14, cosolvent 8 and leveling agent 0.3 , the composition and ratio of the pearl paint ingredients are acrylic modified polyester resin 38, amino resin 4.5, pearl powder 2, amine neutralizer 2, wetting agent 0.3, dispersant 0.3, flame retardant 0.1, ring Oxygen resin 5, defoamer 0.14, cosolvent 8 and levelin...

Embodiment 2

[0043] A method for preparing and spraying baking varnish for a paint bucket, comprising the following steps:

[0044] (1) Ingredients

[0045] Accurately weigh each raw material in turn according to the formula of primer and pearlescent paint;

[0046] (2) pre-mixed

[0047] The prepared water-based resin and amine neutralizer are pre-mixed with a mixer, the time of pre-mixing is 45min, the rotating speed of the mixer is 400r / min, the composition and proportioning of the primer ingredients are water-based resin 43, amino resin 5.5 , iron oxide red 3.5, iron oxide yellow 4.5, amine neutralizer 3.5, wetting agent 0.4, dispersant 0.4, flame retardant 0.15, epoxy resin 6, defoamer 0.35, cosolvent 10 and leveling agent 0.4 , the composition and proportioning of the pearl paint ingredients are acrylic modified polyester resin 41, amino resin 5, pearl powder 5, amine neutralizer 3.5, wetting agent 0.4, dispersant 0.4, flame retardant 0.15, ring Oxygen resin 6, defoamer 0.35, coso...

Embodiment 3

[0059] A method for preparing and spraying baking varnish for a paint bucket, comprising the following steps:

[0060] (1) Ingredients

[0061] Accurately weigh each raw material in turn according to the formula of primer and pearlescent paint;

[0062] (2) pre-mixed

[0063] The prepared water-based resin and amine neutralizer are pre-mixed with a mixer, the time of pre-mixing is 60min, the rotating speed of the mixer is 500r / min, the composition and proportioning of the primer ingredients are water-based resin 46, amino resin 6 , iron oxide red 5, iron oxide yellow 6, amine neutralizer 5, wetting agent 0.5, dispersant 0.5, flame retardant 0.2, epoxy resin 7, defoamer 0.56, cosolvent 12 and leveling agent 0.5 , the composition and ratio of the pearl paint ingredients are acrylic modified polyester resin 44, amino resin 5.5, pearl powder 7, amine neutralizer 5, wetting agent 0.5, dispersant 0.5, flame retardant 0.2, ring Oxygen resin 7, defoamer 0.56, cosolvent 12 and level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com