Polyamide compound material and production method thereof

A composite material and polyamide technology, applied in the field of materials, can solve problems such as unstable mechanical properties, rough surface, easy discoloration of appearance, etc., and achieve excellent stability, low equipment requirements, and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

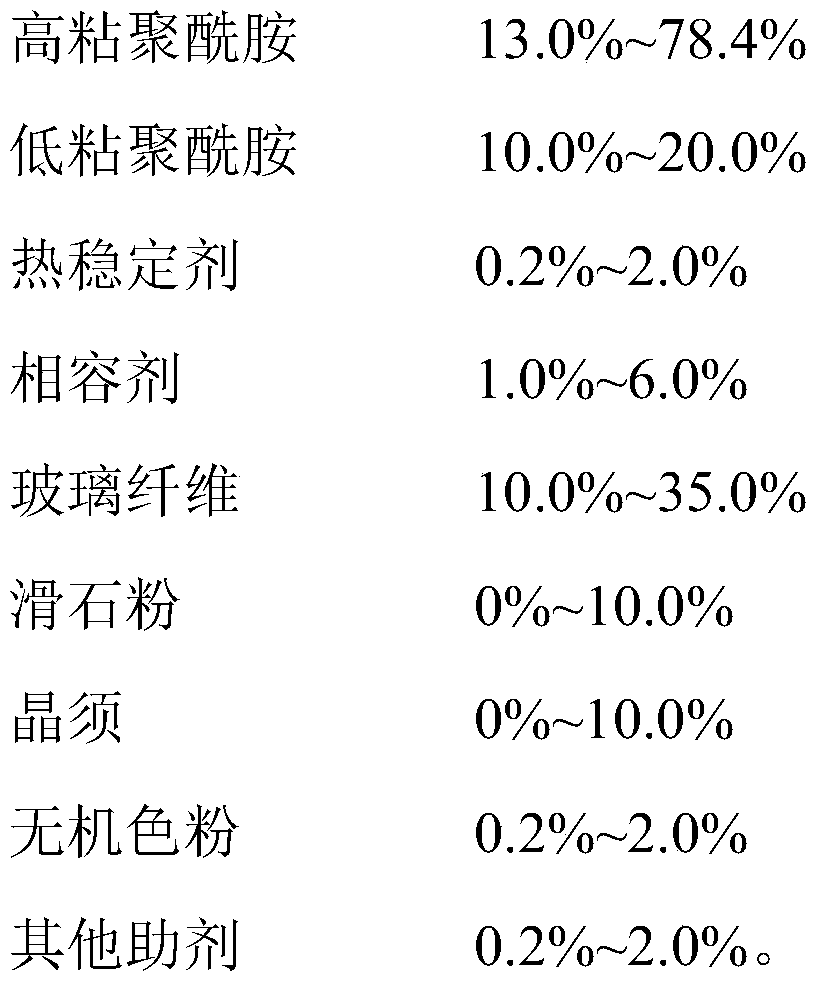

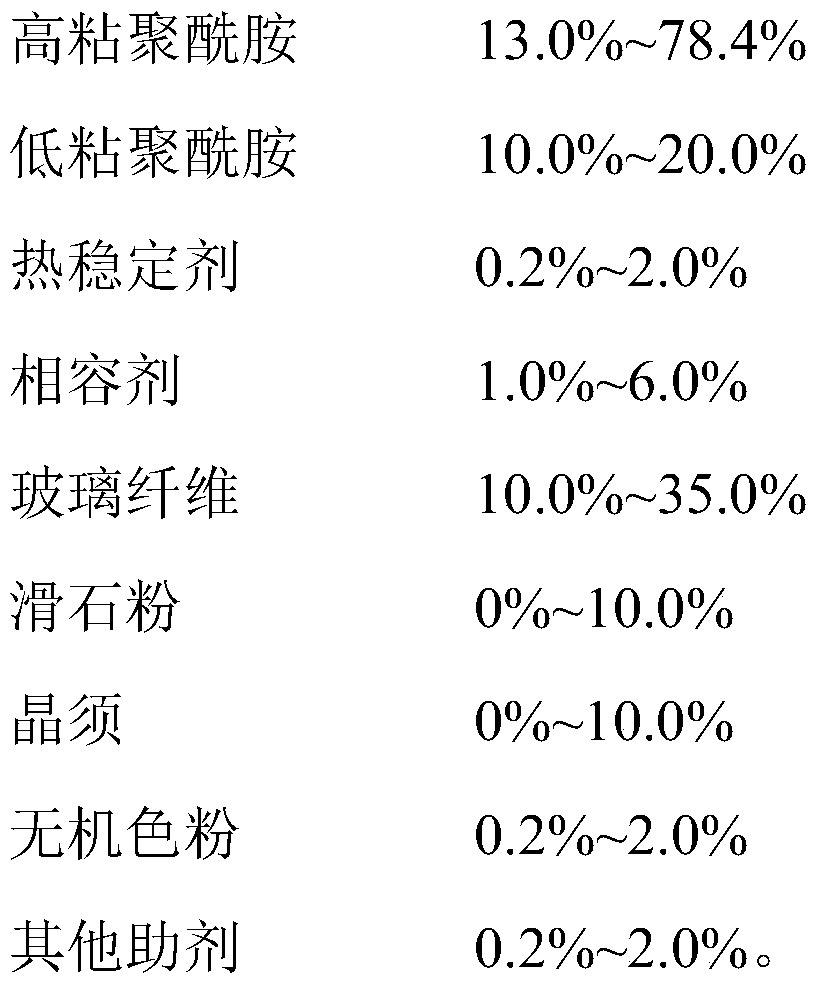

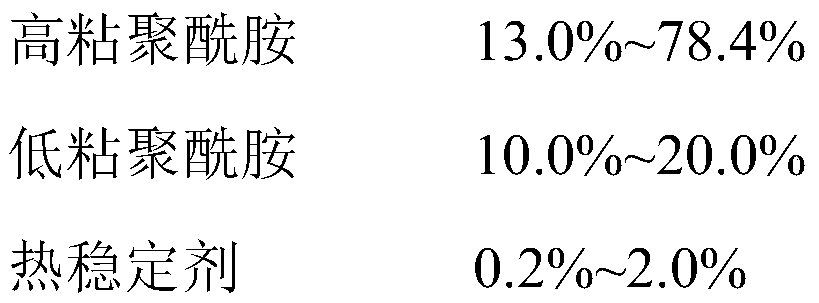

Method used

Image

Examples

preparation example Construction

[0029] Correspondingly, the embodiment of the present invention also provides a preparation method of polyamide composite material. The method comprises the steps of:

[0030] S01. each component is weighed respectively by the composite material of above-mentioned a kind of high and low temperature resistance, stable performance polyamide;

[0031] S02. Mix the high-viscosity polyamide, low-viscosity polyamide, heat stabilizer, auxiliary agent, compatibilizer, talcum powder, whiskers and inorganic toner and put them into the main feeding port of the mixer to obtain the first mixture;

[0032] S03. Put the weighed glass fiber into the side feeding port of the mixer for mixing to obtain the second mixture;

[0033] S04. Melt and mix the second mixture in a twin-screw extruder, then cool, air-dry, pelletize, and mix to obtain a polyamide composite material with high and low temperature resistance and stable performance.

[0034] Specifically, the polyamide composite material w...

Embodiment 1

[0040] A kind of polyamide composite material, the component of described polyamide composite material is as follows: wherein, the viscosity of described high-viscosity polyamide PA6 is 2.8, the viscosity of low-viscosity polyamide PA6 is 2.4, and auxiliary agent comprises nucleating agent, lubricating agent Agents, antioxidants, weathering agents. Inorganic toners include titanium yellow and zinc sulfide. The glass fiber is chopped glass fiber coated with maleic anhydride grafted ethylene-octene copolymer.

[0041] The preparation method of the polyamide composite material is: add 47% high-viscosity polyamide, 10% low-viscosity polyamide, 5% compatibilizer, 10% talcum powder, 5% whiskers, 0.5% hot water from the main feeding port Stabilizer, 1.5% additives and 1% inorganic toner, add coated 20% chopped glass fiber from the side feeding port. After melting and blending in a twin-screw extruder, the particles are obtained by cooling, air-drying, pelletizing and homogenizing. ...

Embodiment 2

[0043] A kind of polyamide composite material, the component of described polyamide composite material is as follows: wherein, the viscosity of described high-viscosity polyamide PA6 is 2.8, the viscosity of low-viscosity polyamide PA6 is 2.0, and auxiliary agent comprises nucleating agent, lubricating agent Agents, antioxidants, weathering agents. Inorganic toners include titanium yellow and zinc sulfide. The glass fiber is chopped glass fiber coated with maleic anhydride grafted ethylene-octene copolymer.

[0044] The preparation method of the polyamide composite material is: add 47% high-viscosity polyamide, 10% low-viscosity polyamide, 5% compatibilizer, 10% talcum powder, 5% whiskers, 0.5% hot water from the main feeding port Stabilizer, 1.5% additives and 1% inorganic toner, add coated 20% chopped glass fiber from the side feeding port. After melting and blending in a twin-screw extruder, the particles are obtained by cooling, air-drying, pelletizing and homogenizing. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com