Novel length measuring and shearing device for soft magnetic stripes

A cutting device and length measurement technology, which is applied in the field of new soft magnetic strip length measurement and shearing device, can solve the problems of high scrap rate, unstable quality, low efficiency, etc., and achieve the effect of stable structure and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

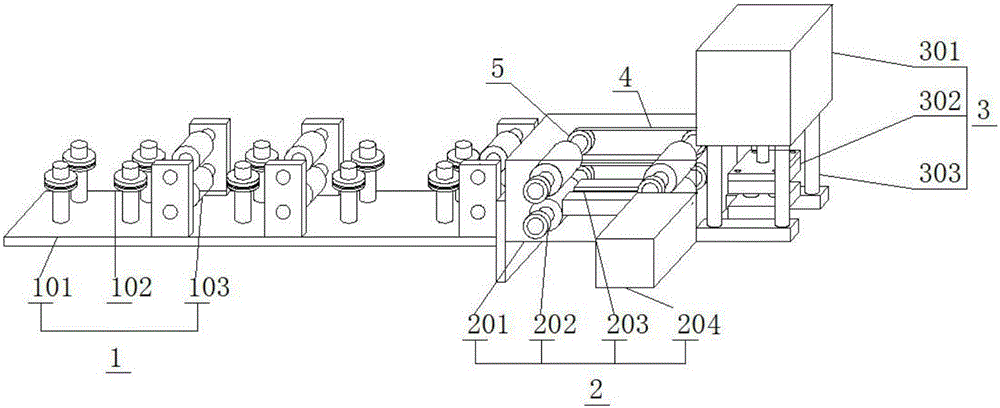

[0014] See the accompanying drawings: a new type of soft magnetic strip length measuring and shearing device, which is characterized in that it includes a magnetic strip straightening device 1 and a magnetic strip sizing conveying device (2, 3), and the magnetic strip straightening device 1 consists of 'T' Shape correction table 101, longitudinal correction pulley 102 and transverse correction pulley 103 are formed, and described magnetic strip sizing conveying device (2,3) comprises magnetic strip sizing device 3 and magnetic strip conveying device 2, and magnetic strip sizing device 3 comprises Cylinder 301, shearing device 302 and support rod 303, magnetic strip conveying device 2 includes protective shell 201, two clamping devices 202, magnetic strip guide groove 203 and servo motor 204, protective shell 201 is divided into magnetic inlet and magnetic outlet A clamping device 202 is installed at the magnetic inlet connected to the magnetic strip straightening device 1, anot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com