Method for loading plasma enhanced chemical vapor deposition equipment and glass panel

An enhanced chemical and vapor deposition technology, which is applied in the direction of gaseous chemical plating, electrical components, semiconductor devices, etc., can solve the problems of high scrap rate of solar cell plates, affecting the quality of coating film, and poor economic benefits, and achieves simple structure and high efficiency. Economic benefits and the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

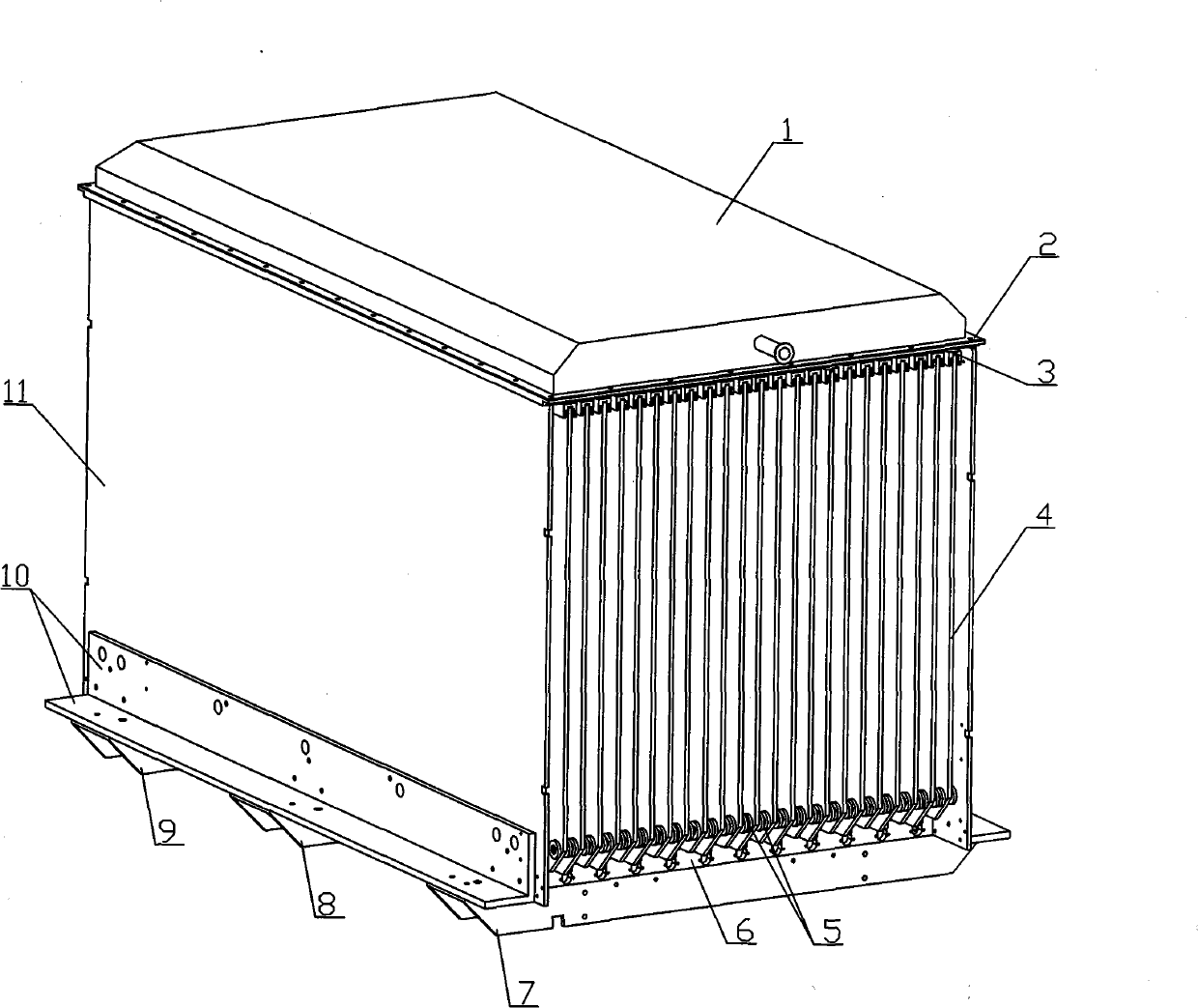

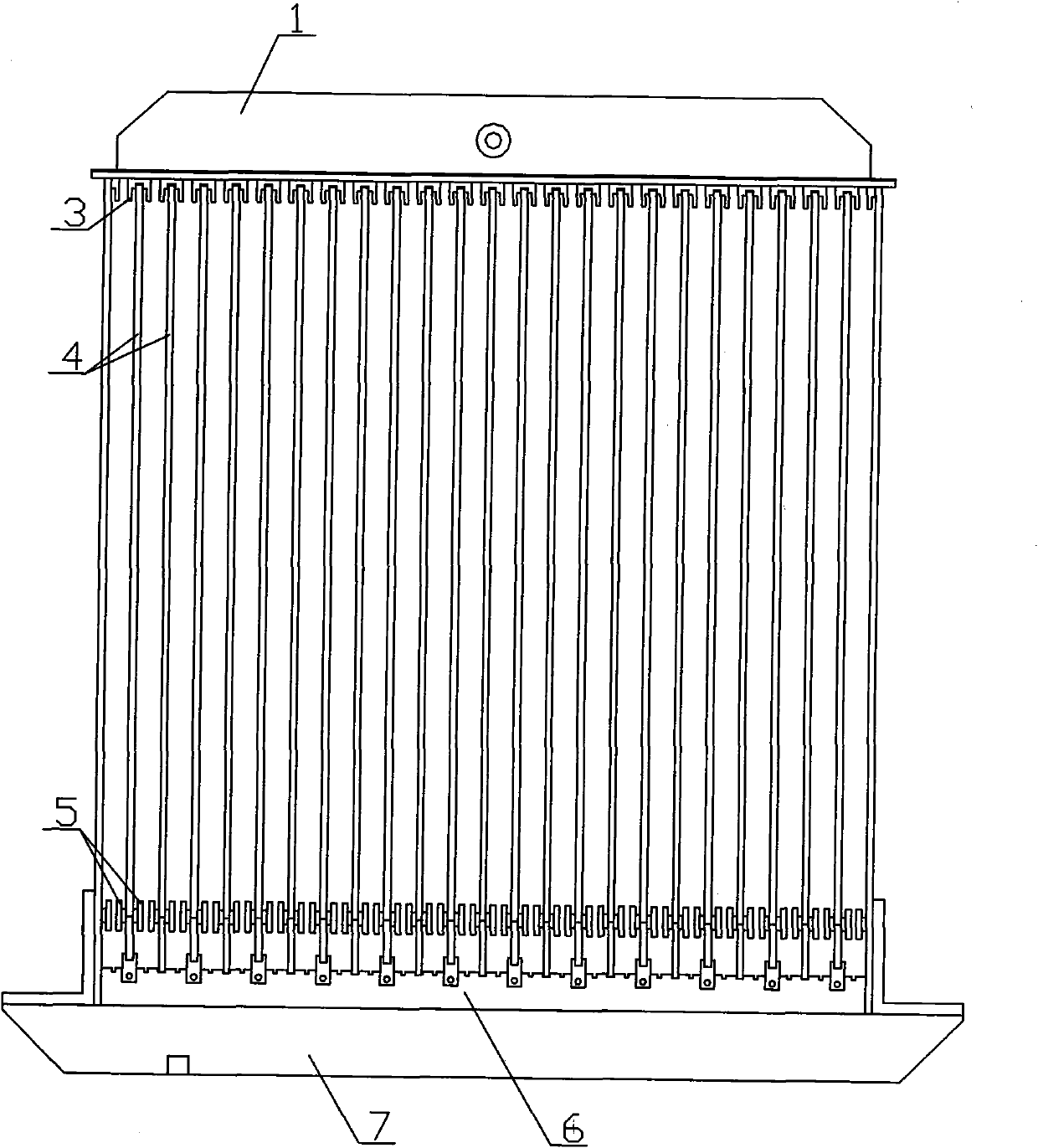

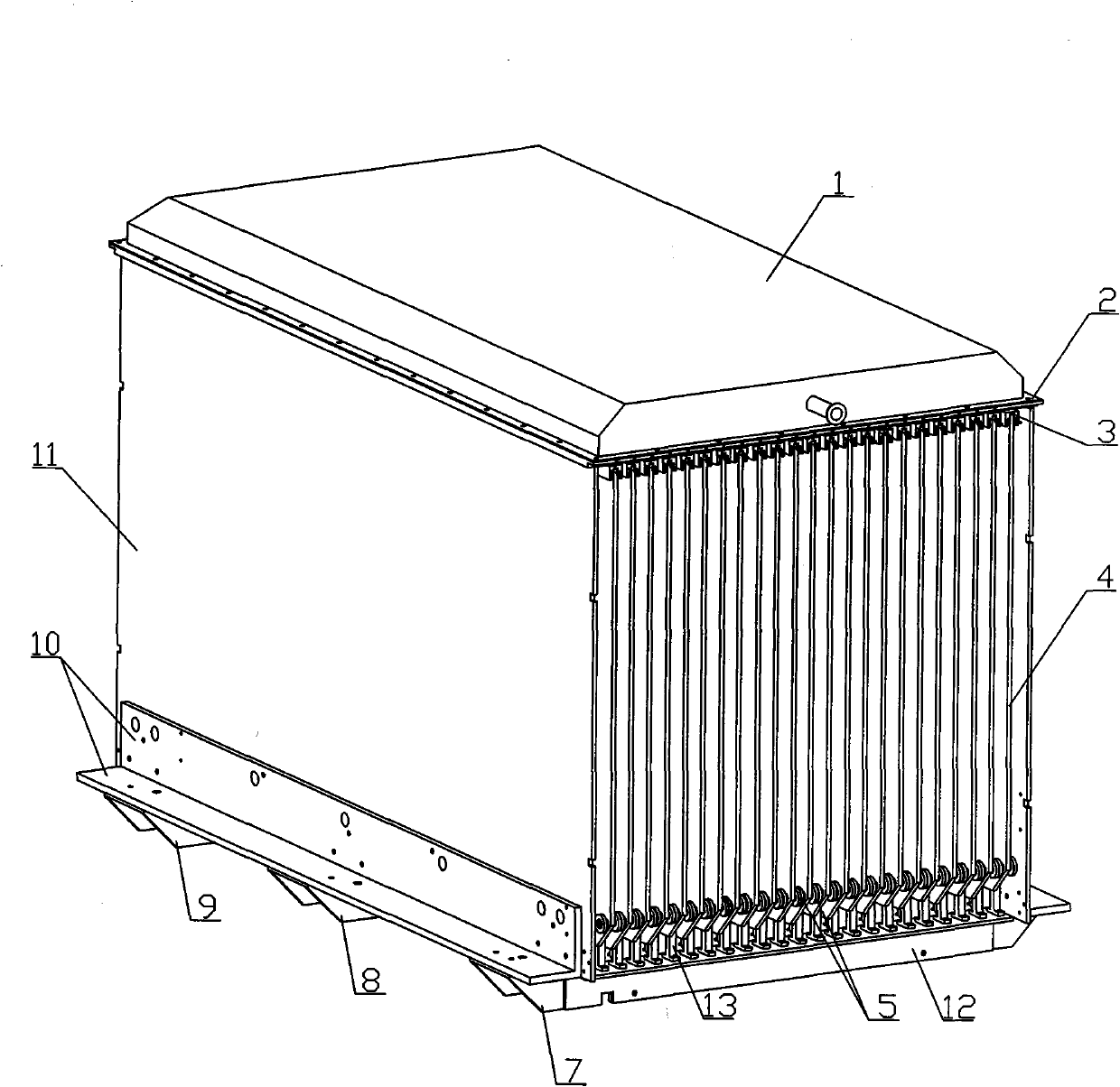

[0069] The invention provides a technical scheme for improving plasma-enhanced chemical vapor deposition equipment, that is, flat-panel PECVD equipment. figure 1 It is a structural schematic diagram of the main part of the flat PECVD equipment in the prior art, including the first U-shaped aluminum groove 7 laid flat on the front end of the bottom of the equipment, the second U-shaped aluminum groove 8 in the middle, and the third U-shaped aluminum groove 9 at the rear end, The two ends of the three U-shaped aluminum grooves are respectively connected by a foot bracket 10 perpendicular to them, and are fixedly connected to the sampans 11 on both sides by the foot bracket 10 . The top of the sampan 11 is connected with a strip top plate 2 by screws, and a top cover 1 is arranged on the strip top plate 2 .

[0070] combine Picture 1-1 As shown, six...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com