Packaging carrier tape producing device

A technology of production device and mounting frame, which is applied to belts, metal processing, other household appliances, etc., can solve the problems of low strength and easy deformation of packaging carrier tape, and achieve the effect of solving low production efficiency, simple structure and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

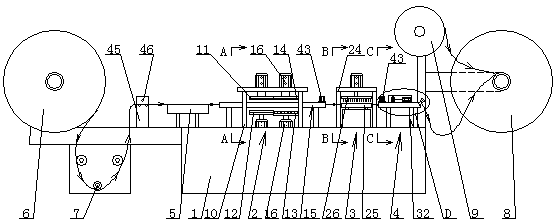

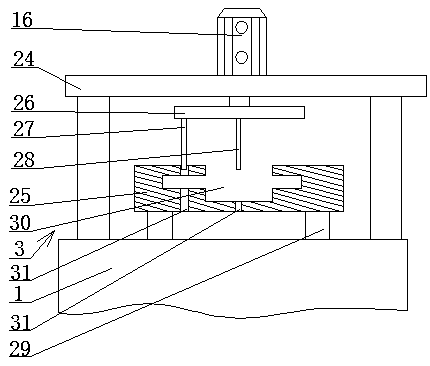

[0028] The packaging carrier tape production device is composed of a machine base 1, a controller, a former 2, a puncher 3 and a tractor 4: the former 2 is arranged on the machine base 1.

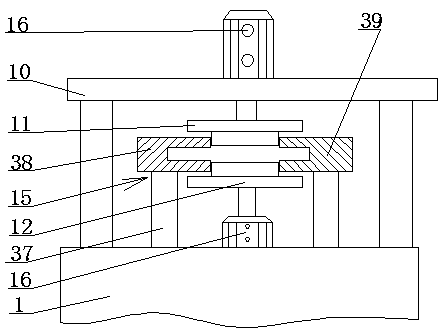

[0029] The forming device 2 is composed of a guide frame A15, an installation frame A10, an upper preheating plate 11, a lower preheating plate 12, a forming convex plate 14 and a forming concave plate 13; the middle part of the base 1 is fixed with a guide frame A15; The upper preheating plate 11 and the forming convex plate 14 are sequentially installed through the mounting frame A10 and the cylinder 16; The original belt can be molded immediately, avoiding when the distance between the upper preheating plate 11 and the forming convex plate 14 is too long, after the preheated original belt cools and hardens, the problem of molding cannot take place.

[0030] On the base 1 below the guide frame A15, a lower preheating plate 12 and a forming concave plate 13 are installed through a cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com