High-efficiency flexible punching and bending anti-theft door plate forming line

A technology of anti-theft doors and forming lines, applied in the direction of feeding devices, manufacturing tools, positioning devices, etc., can solve the problems of reducing the production efficiency of anti-theft door panels, affecting the popularization and use of anti-theft doors, and increasing the labor intensity of workers, so as to achieve optimal automatic molding process, easy to promote and use, and reduce the effect of the probability of excessive bending springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

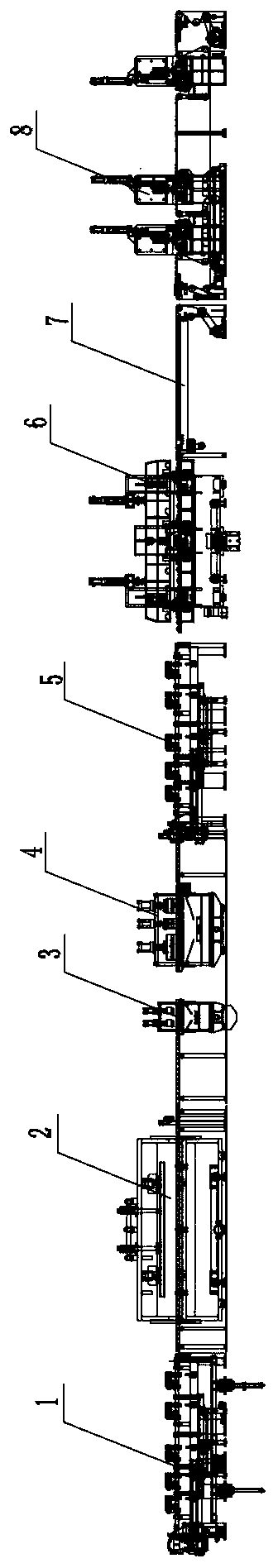

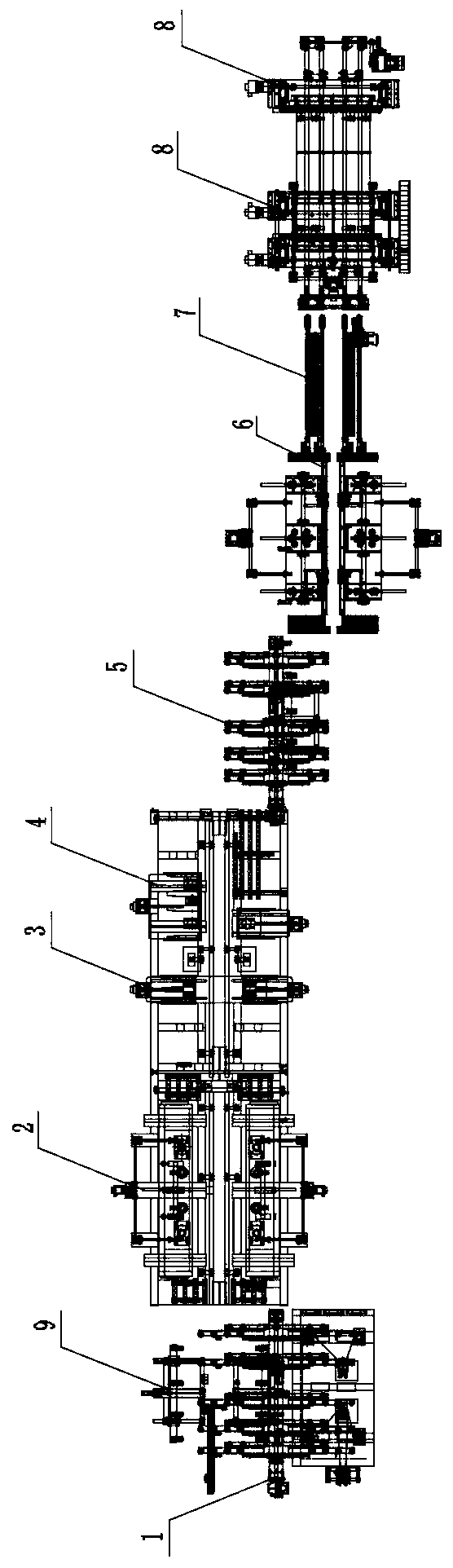

[0050] see Figure 1-11 , the present invention provides a technical solution: a high-efficiency flexible punching anti-theft door panel forming line, including: feeding machine 1, trimming machine 2, No. 1 punching machine 3, No. 2 punching machine 4, turning machine 5 , Side bending machine 6 and end bending machine 8.

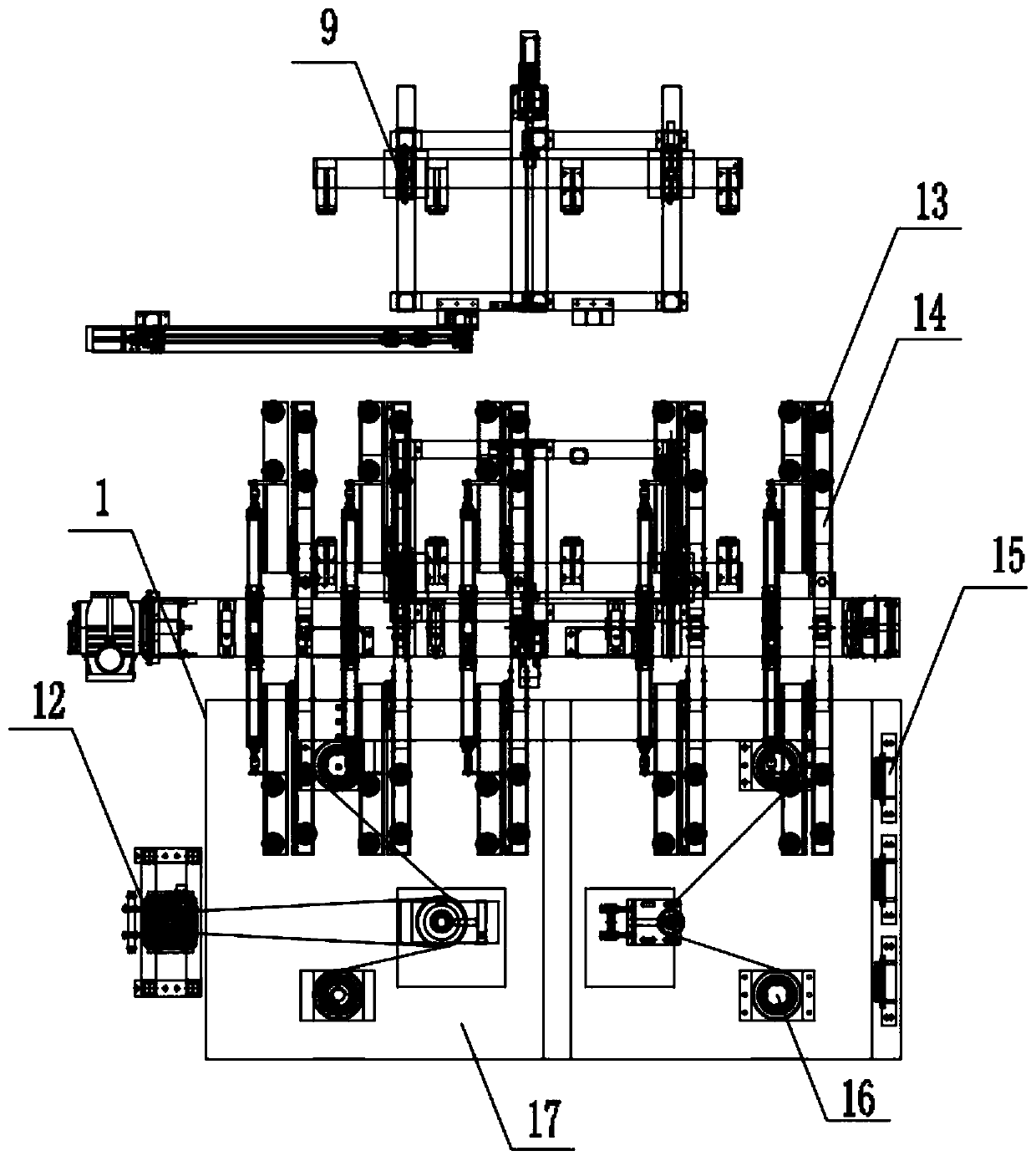

[0051] Wherein, the feeding machine 1 includes a base platform, and one side of the upper end of the base platform is fixed with a No. 1 servo motor 12 and a sprocket screw driving assembly 16 by bolts. The output end of the No. 1 servo motor 12 is connected to the sprocket wire The input ends of the rod drive assembly 16 are connected by belt transmission, the top of the sprocket screw drive assembly 16 is fixedly equipped with a lifting platform 17, and the other side of the upper end of the loading machine 1 is fixedly installed with a feeding turning mechanism. The feeding and turning mechanism includes a motor and a support plate. The upper end of the ...

Embodiment 2

[0082] see Figure 12 , the present invention provides a technical solution: a high-efficiency flexible folding anti-theft door panel forming line, including:

[0083] The manipulator servo adjustment mechanism 11, the manipulator servo adjustment mechanism 11 includes a fixed base plate 27, the upper end side of the fixed base plate 27 is fixedly equipped with a screw mechanism 29, and the screw mechanism 29 includes a No. 3 servo motor 30 and a screw seat , the power output end of the No. 3 servo motor 30 is fixedly connected with a screw rod, and a clamp mechanism 28 is slidably installed on the outside of the screw rod through a sliding nut. The clamp mechanism 28 includes a mounting seat 31, and one end of the mounting seat 31 is A clamp cylinder 33 is fixedly installed by bolts, and the output end of the clamp cylinder 33 is fixedly connected with a clamp head 32 .

[0084] Further, the No. 3 servo motor 30 works to drive the screw to rotate, then the clamp mechanism 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com