Ultralow-temperature vacuum multi-channel combined type dewar

A multi-channel, ultra-low temperature technology, used in pressure vessels, container filling methods, fixed-capacity gas storage tanks, etc., can solve the problems of high processing and scrap rates, high prices, and import-dependent components, and achieve the effect of short connection lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

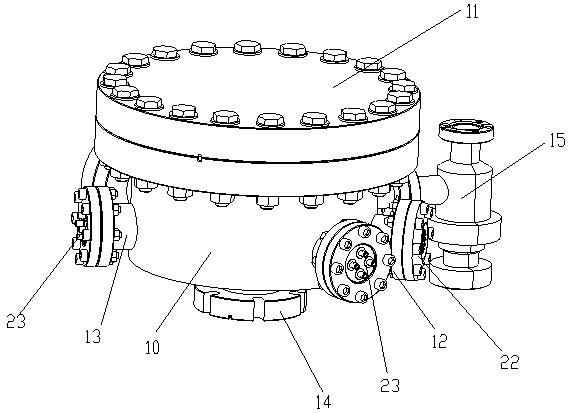

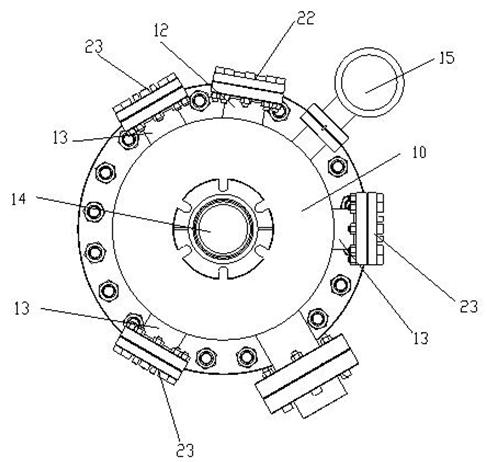

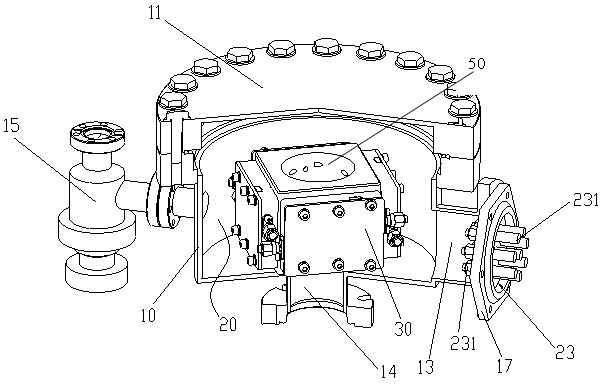

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principle of the present invention will be described through embodiments. Other aspects, features and advantages of the present invention will become clear at a glance through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

[0043] Such as Figures 1 to 3As shown, an ultra-low temperature vacuum multi-channel combined Dewar provided by the embodiment of the present invention includes a Dewar body 10, an airtight cavity 20 is formed in the Dewar body 10, and the bottom of the Dewar body has The flange interface 14 airtightly connected with the refrigerator, the radio frequency circuit 30 operating at ultra-low temperature is installed in the cavity, and the radio frequency circuit 30 is connected with at least one device installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com